Hard Disk Case Producer

1/17

1/17

1/34

1/34

1/26

1/26

1/9

1/9

1/13

1/13

About hard disk case producer

Where to Find Hard Disk Case Producers?

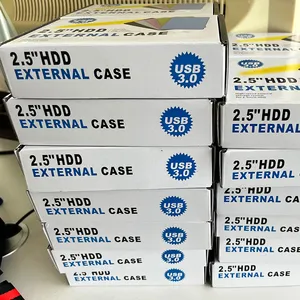

China remains the global epicenter for hard disk case manufacturing, with Shenzhen and Guangzhou serving as primary hubs due to their dense electronics supply chains and specialized OEM infrastructure. These regions host vertically integrated facilities capable of end-to-end production—from injection molding and CNC machining to final assembly—enabling rapid prototyping and scalable output. Suppliers in this ecosystem typically operate dedicated production lines for HDD enclosures, supporting both standard 2.5-inch SATA models and advanced NVMe/M.2 variants with USB 3.0, Type-C, or Thunderbolt 3 interfaces.

The industrial clusters offer significant cost advantages, with localized access to ABS/PC plastics, aluminum extrusions, PCB controllers, and connectors reducing material lead times by up to 40%. This integration allows manufacturers to maintain competitive pricing while achieving monthly production capacities ranging from 10,000 to over 100,000 units per facility. Buyers benefit from flexible MOQs—some as low as one piece—and fast turnaround, with average lead times of 7–15 days for sample orders and 20–30 days for bulk shipments.

How to Choose Hard Disk Case Producers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Production Capabilities

Verify that the manufacturer operates an in-house production line with control over key processes: precision molding for plastic cases, aluminum die-casting or sheet metal fabrication for metal enclosures, and automated PCB integration for data transfer stability. Look for evidence of R&D investment, such as proprietary heat dissipation designs or dual-protocol support (SATA/NVMe). Suppliers advertising "own production line" typically offer better customization flexibility and quality traceability compared to trading companies.

Quality Assurance Metrics

Prioritize partners with documented quality control systems. While formal ISO 9001 certification is not universally listed, performance indicators such as on-time delivery rates above 95%, response times under 3 hours, and reorder rates exceeding 20% correlate strongly with operational reliability. Cross-check these metrics against order history and customer feedback where available. For export compliance, ensure products meet RoHS and CE standards, particularly for European markets.

Procurement Terms & Customization

Assess MOQ requirements relative to your demand volume. Several producers offer single-piece sampling, facilitating low-risk testing. Unit prices vary significantly based on materials and interface type—basic plastic 2.5” cases start below $2.00, while aluminum NVMe enclosures with high-speed protocols can exceed $50.00. Most suppliers accommodate OEM requests including custom branding, color finishes, packaging, and firmware configurations. Confirm whether tooling costs apply for fully customized molds.

What Are the Top Hard Disk Case Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Guangzhou Fengwu New Energy Technology Co., Ltd. | Guangzhou, CN | HDD Enclosure, Hard Drives, RAMs, Testing Equipment | US $50,000+ | 95% | ≤3h | 22% | 10–100 pieces |

| Shenzhen Ayogoo Technology Co., Ltd. | Shenzhen, CN | HDD Enclosure, Hard Drives, RAMs | US $10,000+ | 97% | ≤1h | 21% | 1 piece |

| Shenzhen Greenxi Technology Co., Ltd. | Shenzhen, CN | HDD Enclosure, Optical Drives, Data Cables | US $80+ | 50% | ≤7h | <15% | 1–2 pieces |

| Shenzhen Hongchuangxin Information Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer – HDD Enclosures | US $20,000+ | 94% | ≤1h | 21% | 1 piece / 1 dozen |

| Guangzhou Rihao Electronic Technology Co., Ltd. | Guangzhou, CN | HDD Enclosure, SSD Cases, Data Cables, USB Drives | US $9,000+ | 100% | ≤2h | <15% | 1–100 pieces |

Performance Analysis

Guangzhou Rihao stands out with a perfect 100% on-time delivery record and capabilities in premium segments like Thunderbolt 3 and multi-bay enclosures, though its lower reorder rate suggests room for improvement in customer retention. Shenzhen Ayogoo and Hongchuangxin demonstrate strong responsiveness (≤1h) and low MOQs, ideal for startups or small-scale testing. Guangzhou Fengwu offers broad product diversification and high reorder frequency, indicating stable post-sale satisfaction. In contrast, Shenzhen Greenxi’s 50% on-time delivery rate presents a notable risk despite competitive pricing, warranting deeper due diligence before engagement.

FAQs

How to verify a hard disk case producer’s manufacturing capability?

Request factory audit reports or video tours confirming in-house molding, assembly, and testing lines. Ask for proof of direct ownership via business licenses or equipment registration. Evaluate technical documentation such as compatibility matrices, signal integrity tests, and EMI shielding specifications.

What is the typical sampling timeline?

Standard samples are usually dispatched within 3–7 days. Custom designs involving new molds or circuitry may require 15–25 days for development and validation. Air shipping adds 5–10 days internationally.

Can hard disk case producers handle global exports?

Yes, most established suppliers have experience shipping worldwide via express, air, or sea freight. Confirm Incoterms (e.g., FOB Shenzhen), customs documentation support, and compliance with destination regulations for electronic peripherals.

Do manufacturers provide free samples?

Policies vary. Some suppliers offer paid samples refundable against future orders, while others charge full cost for prototypes. Free samples are rare unless backed by a confirmed purchase intent or long-term partnership discussion.

How to initiate customization projects?

Submit detailed specifications including case dimensions, material preference (ABS, aluminum), supported drive types (SATA/NVMe), interface requirements (USB 3.0, Type-C, Thunderbolt), and branding elements. Reputable producers will respond with engineering drawings, BOMs, and prototype timelines within 48–72 hours.