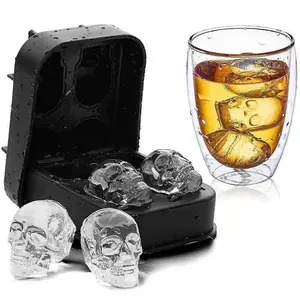

Ice Cube Maker Whiskey

About ice cube maker whiskey

Where to Find Ice Cube Maker Whiskey Suppliers?

China serves as the central hub for ice cube maker whiskey production, with key manufacturing clusters concentrated in Guangdong and Jiangmen regions. These areas host vertically integrated supply chains specializing in food-grade silicone and plastic molding, enabling high-volume output at competitive unit costs. Guangzhou and Shenzhen-based suppliers leverage proximity to polymer processing facilities and export ports, reducing logistics lead times by 20–30% compared to inland manufacturers.

The region’s industrial ecosystem supports rapid prototyping and scalable production runs, with many factories operating dual-material injection molding lines capable of producing BPA-free plastic and platinum-cure silicone variants. Average monthly production capacity among verified suppliers exceeds 100,000 units, supported by automated demolding systems and inline quality inspection protocols. This infrastructure allows for efficient fulfillment of both bulk orders and customized configurations, with typical lead times ranging from 15 to 25 days post-sample approval.

How to Choose Ice Cube Maker Whiskey Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure product compliance and operational reliability:

Material & Food Safety Compliance

Confirm that all products are manufactured using FDA-approved, BPA-free materials. Suppliers must provide test reports verifying compliance with LFGB (Germany), FDA 21 CFR §177.2600 (USA), and EU Regulation (EC) No 1935/2004 for food contact materials. Silicone molds should meet ASTM D2240 Shore A hardness standards (typically 40–60A) for durability and flexibility.

Production and Customization Capability

Assess technical infrastructure through the following benchmarks:

- Minimum factory area of 1,000m² with dedicated clean-room molding sections

- In-house mold design and CNC tooling capabilities for custom cavity development

- Capacity to support Pantone color matching, logo embossing, and multi-cavity configurations (up to 104-grid designs observed)

- Ability to produce both plastic and silicone variants across multiple hardness grades

Cross-reference declared customization options with actual product listings to verify execution capability. Prioritize suppliers offering 3D renderings or physical prototypes within 7–10 days for new designs.

Order Fulfillment Metrics

Analyze supplier performance indicators including on-time delivery rate (>95% recommended), reorder rate (indicative of customer satisfaction), and response time (<4 hours preferred). Minimum order quantities (MOQ) vary significantly—from 50 to 1,000 pieces—impacting suitability for small businesses versus enterprise buyers. Escrow payment terms and transaction protection mechanisms should be standard practice.

What Are the Best Ice Cube Maker Whiskey Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order Quantity | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Raybin Homewares Co., Ltd. | Guangdong, CN | US $590,000+ | 93% | 26% | ≤2h | 100 pcs | Color, material, size, logo, packaging | Plastic ice balls, grid molds |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Shenzhen, CN | US $250,000+ | 93% | <15% | ≤3h | 12–100 sets | Tooling, shape, color, packaging, drawings | Silicone sphere, square crystal, rhombus |

| Shenzhen Huilian Xing Technology Co., Ltd. | Shenzhen, CN | US $300,000+ | 98% | 17% | ≤2h | 50–100 pcs | Color, size, logo, material, packaging | Portable 6-hole, single sphere, iron-clad silicone |

| Jiangmen TW Industry Co., Ltd. | Jiangmen, CN | US $40,000+ | 100% | 42% | ≤4h | 300–1,000 pcs | Limited (customization not emphasized) | Large square, rectangle, Collins molds |

| ShenZhen WeiBu Technology Limited | Shenzhen, CN | US $120,000+ | 93% | 33% | ≤5h | 100 sets | Color, size, logo, packaging, label | Diamond shape, football-shaped, Halloween 3D |

Performance Analysis

Guangzhou Raybin leads in volume scalability and customization breadth, backed by strong online sales performance and responsive communication. Shenzhen Benhaida stands out for technical precision, offering full tooling and shape development services despite a lower reorder rate, suggesting room for service improvement. Shenzhen Huilian Xing demonstrates near-perfect on-time delivery (98%) and low MOQs, making it ideal for niche or trial orders. Jiangmen TW Industry achieves the highest reorder rate (42%), indicating strong buyer retention, though its higher MOQs (500+ units) may limit accessibility for smaller buyers. ShenZhen WeiBu excels in thematic and 3D mold innovation, catering to seasonal or promotional demand cycles.

FAQs

How to verify ice cube maker whiskey supplier reliability?

Validate material certifications (FDA, LFGB, RoHS) through third-party labs like SGS or TÜV. Request batch-specific test reports and conduct factory audits via video walkthroughs focusing on molding lines, QC stations, and packaging areas. Review transaction history for consistent fulfillment patterns and dispute resolution transparency.

What is the average sampling timeline?

Standard samples take 5–10 days for existing molds. Custom designs requiring new tooling typically require 12–18 days, including mold fabrication and first-article inspection. Air shipping adds 3–7 days depending on destination.

Can suppliers ship globally?

Yes, all listed suppliers have established export operations. Confirm Incoterms (FOB, CIF, DDP) during negotiation. Most offer consolidation services for LCL shipments and can provide customs documentation for food-contact goods.

Do suppliers offer free samples?

Policies vary. Some waive fees for qualified buyers committing to minimum volumes (e.g., 500+ units). Others charge partial sample costs (30–70% of unit price), refundable against future orders. Silicone molds often incur higher sampling fees due to tooling complexity.

How to initiate customization requests?

Submit detailed specifications including desired cavity count, dimensions (mm), material type (silicone/plastic), hardness grade, color (Pantone code), and branding requirements (logo placement, packaging design). Reputable suppliers will respond with CAD drawings or 3D models within 72 hours and initiate mold development upon approval.