Ice Sphere Maker Clear

CN

CN

About ice sphere maker clear

Where to Find Ice Sphere Maker Clear Suppliers?

China remains the dominant manufacturing hub for clear ice sphere makers, with key suppliers concentrated in Guangdong and Fujian provinces. These regions host vertically integrated production ecosystems specializing in refrigeration equipment and food-grade plastic molding. Guangzhou-based manufacturers focus on commercial-grade automatic ice sphere machines using direct-cooling technology, achieving crystal-clear block ice output through controlled freezing cycles. Meanwhile, Shenzhen and Xiamen factories specialize in consumer-level silicone molds and reusable acrylic ice alternatives, leveraging advanced injection molding and polymer processing techniques.

The industrial clusters enable cost efficiency and rapid prototyping, supported by localized access to compressors, refrigerants, food-safe silicones, and packaging components. Buyers benefit from scalable production capacity—ranging from small-batch artisanal trays to fully automated 25kg/hour industrial units—with lead times typically between 15–30 days for standard orders. The proximity of material suppliers and logistics networks reduces component procurement delays, allowing for faster fulfillment compared to non-specialized regions.

How to Choose Ice Sphere Maker Clear Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical & Material Compliance

Verify that products meet food safety standards such as FDA, LFGB, or RoHS compliance, particularly for silicone molds and BPA-free plastics. For commercial refrigeration units, confirm adherence to international electrical and mechanical safety norms. Insist on documentation for compressor types (e.g., Danfoss or equivalent), refrigerant class (e.g., R404A, R134a), and cooling cycle efficiency.

Production Capability Assessment

Evaluate supplier infrastructure based on:

- Minimum factory area supporting dedicated assembly lines for ice-making machinery or mold fabrication

- In-house design and tooling capabilities for custom mold configurations (sphere size, cavity layout, ejection mechanism)

- Integration of semi-automatic or fully automatic control systems in machine builds

Cross-reference claimed output capacity with verified order history and on-time delivery performance (target ≥97%).

Customization and Quality Control

Prioritize suppliers offering configurable options including sphere diameter (typically 2–3 inches), freezing time optimization, cabinet insulation thickness, and branding elements (logo imprinting, color variants). Confirm QC protocols such as leak testing for refrigerant circuits, durability testing for mold flexibility, and optical clarity validation for final ice output. Request sample batches to assess consistency in finish, cycle time, and structural integrity.

What Are the Best Ice Sphere Maker Clear Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Koller Refrigeration Equipment Co., Ltd. | Guangdong, CN | Commercial transparent ice block machines, automatic whiskey ice makers | $5,500–$35,800 | 1 set | 84%–100% | ≤4h | 15%–35% | US $120,000+ |

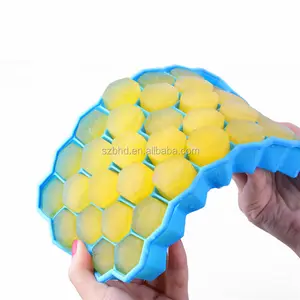

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Guangdong, CN | Silicone ice trays, patented clear ice ball molds | $2.48–$18.80 | 50–100 sets | 97% | ≤3h | 22% | US $230,000+ |

| Xiamen Theone Household Products Co., Ltd. | Fujian, CN | Reusable fake ice cubes, BPA-free plastic molds | $0.02–$21.62 | 3–500 pcs | 98% | ≤2h | <15% | US $10,000+ |

| Yongkang Purplewind Industry & Trade Co., Ltd. | Zhejiang, CN | Silicone ice ball molds, specialty shape trays | $0.80–$12.50 | 3–100 sets | 100% | ≤20h | - | US $2,000+ |

Performance Analysis

Guangzhou Koller stands out for commercial refrigeration solutions, offering high-capacity direct-cooling machines with customization in gearbox, control panels, and refrigerant type. Despite a lower reorder rate at one entity, its dual listings indicate strong market presence and engineering depth. Shenzhen Benhaida leads in consumer mold innovation, backed by patent-protected designs and private-label support, reflected in the highest online revenue and robust reorder metrics. Xiamen Theone excels in low-cost reusable alternatives, catering to event and display markets with ultra-low MOQs and rapid response times. Yongkang Purplewind delivers competitive pricing on silicone molds but shows longer response windows, suggesting limited staffing for international coordination.

FAQs

How to verify ice sphere maker supplier reliability?

Cross-check certifications (ISO 9001, CE, RoHS) with issuing bodies and request test reports for compressor lifespan, freezing cycle stability, and material safety. Analyze transaction data including on-time delivery rates, response speed, and verifiable customer reviews focusing on after-sales service and defect resolution.

What is the average lead time for ice sphere maker orders?

Standard orders typically ship within 15–30 days. Custom configurations involving unique mold dimensions, control systems, or branding may extend lead times to 45 days. Air freight adds 5–10 days globally; sea freight ranges from 25–40 days depending on destination port.

Can suppliers provide free samples?

Sample availability depends on product complexity. For plastic or silicone molds, many suppliers offer paid samples ($10–$20) deductible against future orders. Industrial machines generally require sample fees covering 30–50% of unit cost, non-refundable unless a bulk order follows.

Do manufacturers support OEM/ODM services?

Yes, most verified suppliers offer full customization including logo engraving, color matching (Pantone), packaging design, and technical modifications. Minimum requirements vary: silicone molds often accept 100-unit OEM runs, while industrial machines may require 5+ units for configuration changes.

What are typical payment terms for first-time buyers?

Common structures include 30% T/T deposit with 70% before shipment, or use of trade assurance programs for escrow protection. Letters of credit (L/C) are available for large-scale industrial purchases. Negotiate milestone payments for custom-engineered systems exceeding $10,000.