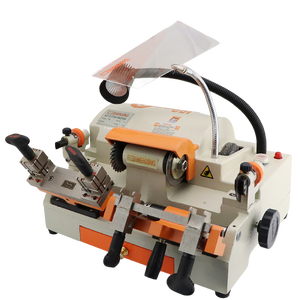

Kroger Key Maker

About kroger key maker

Where to Find Kroger Key Maker Suppliers?

China remains the central hub for key cutting and duplication machinery manufacturing, with supplier clusters concentrated in Henan and Guangdong provinces. Henan-based suppliers dominate volume production of mechanical key duplicators, leveraging regional logistics advantages and vertically integrated component sourcing. Guangdong, particularly Shenzhen, specializes in electronic key programming systems and remote control chip solutions, supported by dense electronics supply chains and R&D expertise in automotive diagnostics.

These industrial ecosystems enable rapid prototyping and scalable production, with many suppliers operating end-to-end facilities that integrate CNC machining, assembly, and quality testing under one roof. Buyers benefit from localized access to molds, motors, and electronic modules, reducing lead times by 20–30% compared to offshore alternatives. The average production cycle for standard key makers ranges from 15 to 30 days, with express processing options available for orders under 10 units. Regional specialization allows for both cost-effective mechanical models and advanced programmable systems tailored to retail and locksmith applications.

How to Choose Kroger Key Maker Suppliers?

Procurement decisions should be guided by technical capability, transaction reliability, and post-sale support verification.

Technical and Functional Compliance

Ensure equipment compatibility with common key profiles used in commercial settings, including flat steel keys, tubular keys, and transponder-equipped automotive keys. For suppliers offering electronic key programmers, confirm firmware support for major brands (e.g., Toyota, Volkswagen, Ford) and verify inclusion of diagnostic tools or cloud-based software updates. While formal certifications like CE or RoHS are not universally declared in supplier data, request compliance documentation where applicable—especially for EU or North American market distribution.

Production and Customization Capacity

Evaluate suppliers based on demonstrated flexibility:

- Minimum Order Quantity (MOQ) ranging from 1 to 4 pieces, indicating suitability for small retailers or pilot testing

- Customization capabilities including logo labeling, color variation, packaging design, and machine engraving options

- Availability of multi-functional models supporting both cutting and remote programming

Prioritize suppliers advertising customization tags and low MOQs for agile sourcing strategies.

Transaction Reliability Indicators

Analyze performance metrics provided by digital platforms:

- On-time delivery rates exceeding 97% signal operational efficiency

- Response times under 3 hours reflect strong customer service infrastructure

- Reorder rates above 25% indicate buyer satisfaction and product reliability

Cross-reference these metrics with annual online revenue estimates (e.g., US $300,000+ performers) to assess scalability and market validation.

What Are the Best Kroger Key Maker Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Henan Locks Trading Co., Ltd. | Henan, CN | Key Cutting Machines, Car Key Copiers | $70–$500 | 1–2 pieces | 99% | ≤1h | US $210,000+ | 18% |

| Hunan Kukai Electromechanical Co., Ltd. | Hunan, CN | Locksmith Programmers, Copy Key Machines | $1,895–$2,995 | 1–2 sets | 100% | ≤5h | US $3,000+ | - |

| Shenzhen Automan Technology Co., Ltd. | Guangdong, CN | Car Key Remotes, Diagnostic Tools | $25–$99 | 1 box | 94% | ≤4h | US $90,000+ | 18% |

| Henan Jinfuda Trading Co., Ltd. | Henan, CN | Automatic Key Cutters, Chip Copy Machines | $79–$2,145 | 1 piece | 98% | ≤3h | US $570,000+ | <15% |

| Shenzhen Topbest Technology Co., Limited | Guangdong, CN | Smart Key Makers, Horizontal Cutters | $75–$2,250 | 1–2 pieces | 100% | ≤3h | US $310,000+ | 27% |

Performance Analysis

Henan-based suppliers offer competitive pricing on mechanical key duplicators, with models starting at $70 and strong fulfillment records (98–99% on-time delivery). Shenzhen’s technology-focused vendors provide higher-value solutions such as programmable remote makers and diagnostic-compatible devices, though at elevated price points. Notably, Shenzhen Topbest Technology stands out with a 27% reorder rate and full on-time delivery record, suggesting high end-user satisfaction despite mid-tier response speed. Henan Jinfuda leads in transaction volume (US $570,000+), indicating robust export activity and broad market reach. For budget-conscious buyers, entry-level cutters from Hunan Kukai or Shenzhen Automan present viable options, while large-scale operators may prioritize customizable, high-throughput machines from verified multispecialty suppliers.

FAQs

How to verify Kroger key maker supplier reliability?

Cross-check on-time delivery rates and response times against platform-verified transaction histories. Request evidence of after-sales support, such as firmware update policies or technical troubleshooting channels. For electronic models, verify compatibility with common key types through product specifications or sample testing.

What is the typical lead time for key maker orders?

Standard production and dispatch take 15–25 days post-payment confirmation. Express processing may reduce this to 7–10 days for single-unit shipments. Add 5–12 days for international air freight depending on destination region.

Can suppliers customize key making machines?

Yes, multiple suppliers explicitly list customization options—including color, material, logo imprinting, packaging, and label design—allowing branding alignment for retail deployment. Confirm tooling requirements and associated NRE (non-recurring engineering) fees before order placement.

Do suppliers offer free samples?

Sample availability varies. Some suppliers may provide paid samples at near-production cost (e.g., $70–$150), which can be credited toward bulk orders. Free samples are uncommon unless MOQ thresholds exceed five units.

Are there shipping and import considerations?

Most suppliers support global shipping via air or sea freight under FOB or CIF terms. Buyers must verify voltage compatibility (e.g., 110V vs. 220V), ensure compliance with local electrical safety standards, and account for potential import duties on electromechanical equipment.