Label Machine For Jars

CN

CN

Top sponsor listing

Top sponsor listing

1/24

1/24

1/22

1/22

1/13

1/13

About label machine for jars

Where to Find Label Machine for Jars Suppliers?

China remains the global epicenter for labeling machinery manufacturing, with key production clusters in Guangdong, Zhejiang, and Tianjin offering specialized capabilities for jar and bottle labeling systems. Guangdong’s Dongguan and Shenzhen regions host advanced automation suppliers leveraging integrated electronics and precision engineering ecosystems. Zhejiang’s Hangzhou and Wenzhou zones focus on intelligent control systems and high-speed rotary labeling technology, supported by regional R&D investments exceeding $50 million annually. Tianjin’s proximity to Beijing-Tangshan industrial corridors enables cost-efficient access to mechanical components and CNC fabrication resources.

These hubs provide vertically integrated supply chains—spanning servo motor sourcing, stainless steel fabrication, and PLC programming—allowing rapid prototyping and scalable production. Buyers benefit from localized vendor networks where assembly, testing, and packaging occur within 30–50 km radii, reducing logistics overhead. Typical lead times range from 15–30 days for standard units, with production costs 20–35% below Western counterparts due to optimized labor and material efficiency. The concentration of OEMs and ODMs supports both bulk procurement (MOQs as low as 1 set) and technical customization across labeling accuracy, container compatibility, and integration with existing packaging lines.

How to Choose Label Machine for Jars Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

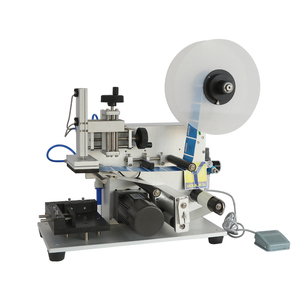

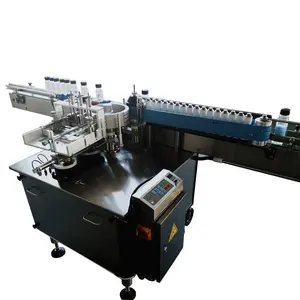

Verify adherence to international safety and performance standards such as CE and ISO 9001. For export-bound equipment, confirm electrical compatibility (e.g., 220V/50Hz or 110V/60Hz configurations) and compliance with destination-market regulations. Assess design flexibility—top suppliers offer customization in labeling speed (up to 600 bottles/min), label size (height: 20–150mm), container diameter (φ20–150mm), and mounting configurations (desktop, inline, or standalone).

Production Infrastructure Assessment

Evaluate core manufacturing competencies through objective indicators:

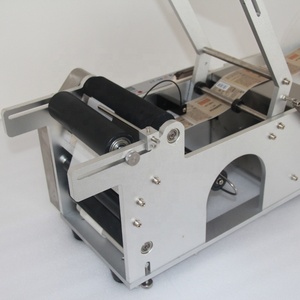

- Facility scale supporting dedicated assembly lines for semi-automatic and fully automatic models

- In-house engineering teams capable of modifying HMI interfaces, sensor calibration, and conveyor integration

- On-site testing protocols for adhesive consistency, label registration accuracy (±0.5mm), and machine durability under continuous operation

Cross-reference response time metrics (target ≤4 hours) and on-time delivery rates (preferably ≥97%) as proxies for operational reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms tied to milestone verification, especially for first-time engagements. Prioritize suppliers with documented quality control processes, including pre-shipment inspection reports and video validation of functional tests. Request sample units to evaluate labeling precision, noise levels (<75 dB), and ease of changeover between jar types. Confirm after-sales support availability for troubleshooting and spare parts replacement.

What Are the Best Label Machine for Jars Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Product Range |

|---|---|---|---|---|---|---|---|---|

| Guangdong Smart Weigh Packaging Machinery Co., Ltd. | Guangdong, CN | Multi-Function Packaging Machines, Filling Machines, Vacuum Packers | Labeling logo, tray size, graphic weigher, packaging type | 100% | ≤4h | <15% | US $500+ | 15+ models |

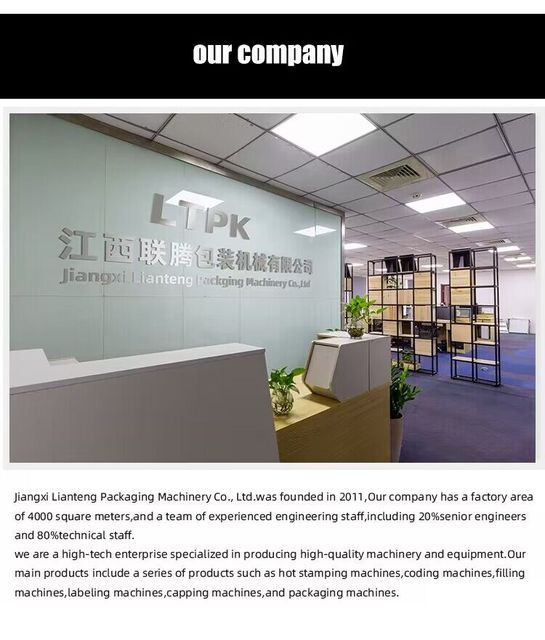

| Zhejiang Lianteng Intelligent Equipment Co., Ltd. | Zhejiang, CN | Semi-Automatic & High-Speed Desktop Labelers | Label height, material size, color, packaging style | 97% | ≤6h | 17% | US $370,000+ | 5 models |

| Tianjin Futa Machinery Equipment Co., Ltd. | Tianjin, CN | Semi-Automatic & Automatic Plastic Labelers | Single/double-side labeling, sticker type, container shape | 100% | ≤2h | 28% | US $60,000+ | 5 models |

| Dongguan Skyone Tech Co., Ltd. | Guangdong, CN | Automatic Round Bottle & Desktop Labeling Machines | Label placement, speed settings, machine footprint | 100% | ≤3h | 18% | US $50,000+ | 5 models |

| Shenzhen Yichengxing Electronic Co., Ltd. | Shenzhen, CN | Manual & Small-Scale Label Applicators | Orientation labeling, handheld configuration, compact design | 100% | ≤4h | <15% | US $7,000+ | 5 models |

Performance Analysis

Guangdong-based suppliers like Guangdong Smart Weigh and Dongguan Skyone demonstrate strong integration with broader packaging lines, making them suitable for businesses seeking end-to-end automation. Zhejiang Lianteng stands out with a high online revenue volume and offerings in high-speed desktop systems, indicating market trust and export readiness. Tianjin Futa excels in responsiveness (≤2h average reply) and repeat business (28% reorder rate), suggesting robust customer satisfaction despite mid-tier revenue. All top-tier suppliers maintain 100% on-time delivery except Zhejiang Lianteng (97%), a minor deviation within acceptable thresholds for high-volume exporters. Manual and entry-level equipment from Shenzhen Yichengxing serves startups and small-batch producers with budget constraints, priced as low as $85 per unit.

FAQs

How to verify label machine supplier reliability?

Validate certifications (CE, ISO) through official registries and request product test videos demonstrating labeling accuracy and cycle stability. Analyze transaction history, focusing on consistent delivery performance and post-sale communication. Third-party inspection services can audit factory operations remotely or on-site prior to large orders.

What is the typical lead time for label machines?

Standard models ship within 15–20 days after order confirmation. Customized systems require 25–35 days depending on complexity. Air freight delivers samples in 5–7 days; sea freight takes 20–40 days based on destination port congestion.

Can suppliers accommodate low MOQs?

Yes, most suppliers list minimum orders of 1 set, particularly for semi-automatic and desktop models. This enables pilot testing and scalability assessment without significant upfront investment.

Do manufacturers support technical customization?

Leading suppliers offer modifications in labeling mechanism (wrap, front/back, top), sensor type (optical, capacitive), power supply, and integration with conveyors or fillers. Provide detailed specifications including jar dimensions, label material (paper, PVC, PET), and production line speed for accurate quoting.

Are samples available before bulk ordering?

Sample availability varies. Some suppliers offer paid samples (typically 30–50% of unit cost) refundable against future orders. Free samples are rare but negotiable for high-potential long-term contracts.