Lathe Machine Turning Operation

CN

CN

About lathe machine turning operation

Where to Find Lathe Machine Turning Operation Suppliers?

China remains the global epicenter for lathe machine manufacturing, with key production clusters in Guangdong and Liaoning provinces driving innovation and cost efficiency. Shenzhen-based suppliers dominate the mid-range manual and combo lathe segment, leveraging dense industrial ecosystems for rapid component sourcing and assembly. Dalian and Hangzhou manufacturers specialize in high-precision CNC and heavy-duty models, benefiting from proximity to advanced metallurgical and automation supply chains that reduce material costs by 15–25% compared to non-Asian producers.

These regions support vertically integrated operations—from gear machining and spindle fabrication to final testing—enabling lead times as low as 20–35 days for standard configurations. The concentration of technical talent and logistics infrastructure allows suppliers to scale production efficiently, offering MOQs starting at 1 set while maintaining competitive pricing across manual, semi-automatic, and CNC categories. Buyers gain access to flexible production runs, robust customization options, and reliable export channels serving North America, Europe, and Southeast Asia.

How to Choose Lathe Machine Turning Operation Suppliers?

Effective supplier selection requires a structured evaluation of technical, operational, and transactional performance metrics:

Technical & Quality Compliance

Verify adherence to international quality standards such as ISO 9001. For CNC and high-precision models, confirm CE marking to ensure compliance with European safety and electromagnetic compatibility directives. Request documentation on spindle runout tolerance (typically ≤0.005mm), surface finish consistency, and dynamic balancing reports for rotating components.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area exceeding 3,000m² for sustained output

- In-house capabilities in gear cutting, spindle grinding, and control system integration

- Dedicated R&D or engineering teams supporting custom modifications

Cross-reference online revenue indicators and on-time delivery rates (target ≥90%) to assess operational stability and order fulfillment reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with delivery milestones. Prioritize suppliers with documented quality control processes, including pre-shipment inspection protocols and traceable component sourcing. Conduct sample testing to validate swing diameter accuracy, feed rate consistency, and tool post rigidity before scaling orders.

What Are the Best Lathe Machine Turning Operation Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization | Product Range | Min. Order |

|---|---|---|---|---|---|---|---|---|

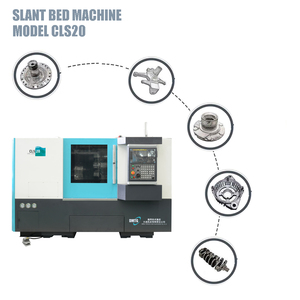

| Dalian Jori Co., Ltd. | Liaoning, CN | US $320,000+ | 100% | 40% | ≤2h | Yes | CNC, Slant Bed, Universal | 1 unit |

| Hangzhou Techmax Precision Machinery Co., Ltd. | Zhejiang, CN | US $600,000+ | 100% | <15% | ≤4h | Yes | CNC, Heavy-Duty, Automatic | 1 set |

| Shenzhen Integrity Industry Co., Ltd. | Guangdong, CN | US $120,000+ | 93% | 15% | ≤2h | Yes | Manual, Bench, Multi-Purpose | 1 set |

| Shenzhen Richon Industry Co., Ltd. | Guangdong, CN | US $290,000+ | 88% | 15% | ≤2h | Yes | Combo, Mini, Inclined Bed | 1 set |

| Shenzhen Shengmingfa Technology Co., Ltd. | Guangdong, CN | US $30,000+ | 100% | 20% | ≤5h | No | Manual, Used, Heavy-Duty | 1–2 sets |

Performance Analysis

Dalian Jori stands out with a 40% reorder rate and full on-time delivery record, indicating strong customer satisfaction and process reliability, particularly in CNC and automated lathe segments. Hangzhou Techmax leads in revenue volume and technical capability, offering high-precision CNC lathes with customization support despite a lower reorder rate, suggesting focus on larger, infrequent contracts. Shenzhen-based suppliers provide cost-effective solutions for entry-level and multi-functional machines, with response times under 2 hours enhancing buyer engagement. Shengmingfa distinguishes itself by offering used and refurbished units at competitive prices, though limited customization and longer response windows may affect complex procurement needs.

FAQs

How to verify lathe machine supplier reliability?

Validate certifications through issuing bodies and request audit trails for quality control procedures. Analyze transaction history, focusing on consistent on-time delivery, dispute resolution transparency, and verifiable customer feedback regarding machine durability and after-sales service.

What is the typical lead time for lathe machines?

Standard manual and bench lathes ship within 20–30 days. CNC and heavy-duty models require 35–50 days due to complex assembly and calibration. Custom configurations may extend lead times by an additional 10–15 days.

Can suppliers accommodate customization requests?

Yes, leading suppliers offer modifications including variable speed spindles, specialized tool posts, custom chuck diameters, and branding elements like logo engraving. Confirm feasibility through technical drawings and prototyping agreements prior to order placement.

What are common MOQs for lathe machines?

Most suppliers list MOQs at 1 set or unit, especially for high-value CNC and industrial models. Some may require 2 sets for discounted or refurbished units. Bulk pricing typically applies at 5+ units.

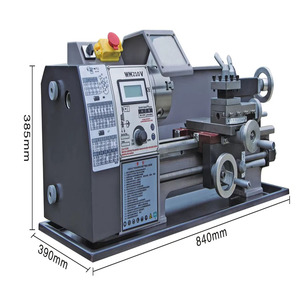

How to evaluate machine specifications before purchasing?

Review critical parameters: swing over bed (ranging from 200mm to 630mm), distance between centers, spindle bore diameter, motor power, and feed mechanism type. Request test cut videos or dimensional accuracy reports to validate performance claims.