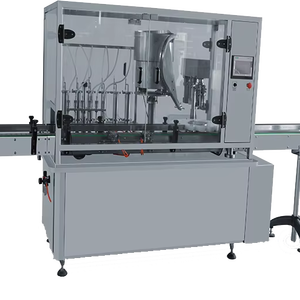

Linear Screw Capping Machine

About linear screw capping machine

Where to Find Linear Screw Capping Machine Suppliers?

China remains the global epicenter for linear screw capping machine manufacturing, with key production clusters in Guangdong and Shanghai driving innovation and cost efficiency. Guangdong-based suppliers leverage proximity to advanced electronics and automation component hubs, enabling integration of servo-driven controls and digital HMI interfaces at competitive price points. Shanghai’s industrial ecosystem specializes in high-speed, fully automatic packaging lines, offering integrated solutions that combine filling, capping, and labeling systems.

These regions benefit from vertically integrated supply chains—spanning CNC machining, electrical assembly, and robotic integration—allowing for rapid prototyping and scalable production. Facilities typically operate within 50km of critical subsystem suppliers, reducing lead times by up to 25% compared to decentralized markets. Buyers gain access to standardized models with lead times averaging 30–45 days, while custom configurations are fulfilled within 45–60 days. Cost advantages range from 20–35% over European or North American manufacturers due to lower labor and overhead expenses.

How to Choose Linear Screw Capping Machine Suppliers?

Selecting reliable partners requires adherence to structured evaluation criteria:

Technical Compliance

Verify ISO 9001 certification as a baseline for quality management systems. For export to regulated markets (EU, USA), confirm CE marking and compliance with machinery safety directives (e.g., 2006/42/EC). Request documentation on motor ratings, torque control systems, and material compatibility—particularly for corrosive or viscous liquids. Stainless steel (SUS304/SUS316) contact parts should meet food-grade or pharmaceutical standards where applicable.

Production Capability Audits

Assess infrastructure maturity through objective metrics:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house engineering teams capable of customizing cap diameter, bottle height, and torque settings

- On-site CNC machining and welding capabilities to ensure component traceability

Cross-reference online revenue data and on-time delivery rates (target ≥90%) to validate operational stability and order fulfillment consistency.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services until post-delivery performance verification. Prioritize suppliers with documented reorder rates above 40%, indicating customer satisfaction and product reliability. Conduct pre-shipment inspections or request factory videos demonstrating live machine testing under real operating conditions. Sample validation is recommended—test capping accuracy across 1,000 cycles to assess torque consistency and cap alignment.

What Are the Best Linear Screw Capping Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shanghai Grepack Packing Machinery Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $1,000,000+ | 100% | ≤3h | 50% | $5,000–20,000 | Yes |

| Guangdong Shanghang Technology Limited | Guangdong, CN | Custom Manufacturer | US $1,200,000+ | 95% | ≤4h | 19% | $4,799–8,499 | Yes |

| Nantong Yuquan Machinery Technology Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $140,000+ | 75% | ≤2h | 50% | $1,350–8,200 | Yes |

| YUXUN INDUSTRY INC | Unknown | Not Specified | Not Disclosed | Not Available | ≤4h | Not Available | $3,100–5,300 | Limited Data |

Performance Analysis

Shanghai Grepack stands out with a 100% on-time delivery rate and a 50% reorder rate, indicating strong customer retention and process reliability. Its higher price band reflects investment in servo-driven systems and full-line integration capabilities. Guangdong Shanghang offers premium build quality with ZONESUN-branded machines targeting cosmetic and dropper applications, though its lower reorder rate suggests room for improvement in after-sales service. Nantong Yuquan provides the broadest price range, including semi-automatic options ideal for SMEs, supported by responsive communication and mid-tier performance metrics. YUXUN presents entry-level pricing but lacks verifiable delivery and revenue data, warranting additional due diligence before procurement.

FAQs

How to verify linear screw capping machine supplier reliability?

Cross-check ISO and CE certifications with issuing bodies. Request third-party audit reports covering design validation, material sourcing, and quality control procedures. Analyze transaction history for consistent on-time delivery and examine customer reviews focusing on technical support responsiveness and machine uptime.

What is the average sampling timeline?

Standard sample production takes 15–25 days. Customized units with specialized grippers, torque sensors, or PLC programming require 30–45 days. Air freight shipping adds 7–10 days internationally.

Can suppliers ship globally?

Yes, most established manufacturers offer FOB and CIF shipping terms with containerized sea freight as the economical choice for full-line installations. Confirm compliance with destination country electrical standards (voltage, frequency) and customs requirements for industrial machinery.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for orders exceeding one unit; others charge 30–50% of unit cost, redeemable against future bulk purchases. Fully automated models rarely qualify for free sampling due to high setup costs.

How to initiate customization requests?

Submit detailed specifications including bottle dimensions (diameter, height), cap type (screw, dropper, pump), required torque range (N·cm), and production speed (bottles per minute). Leading suppliers provide CAD drawings or 3D renderings within 72 hours and functional prototypes within 3–4 weeks.