Lmw Cnc Machine Price In Coimbatore

About lmw cnc machine price in coimbatore

Where to Find LMW CNC Machine Suppliers in Coimbatore?

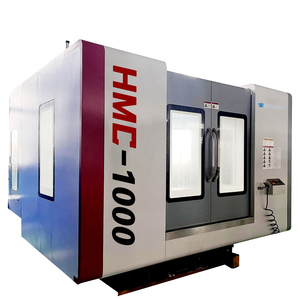

While Coimbatore serves as a key industrial hub in South India for precision engineering and machine tool adoption, the manufacturing base for LMW-branded CNC machines is primarily concentrated in China. Indian buyers sourcing "LMW CNC machine price in Coimbatore" typically engage with Chinese suppliers who export directly or through regional distributors. Major production clusters are located in Shandong and Jiangsu provinces, where vertically integrated facilities support end-to-end machining center production.

These regions benefit from mature supply chains for cast iron beds, ball screws, linear guides, and servo systems, enabling competitive pricing and scalable output. Shandong-based manufacturers, in particular, operate large-scale plants with dedicated R&D units focused on vertical machining centers (VMC) and CNC lathes—core product lines associated with LMW-class performance standards. Export-oriented factories maintain inventory buffers and pre-shipment testing protocols, ensuring lead times of 30–45 days for standard configurations. Buyers in Coimbatore gain cost advantages of 20–30% compared to European or Japanese suppliers, with flexibility for technical customization.

How to Choose LMW CNC Machine Suppliers?

Selecting reliable suppliers requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm alignment with LMW-equivalent specifications: FANUC-compatible controls, BT40/BT50 spindle interfaces, and three-axis travel ranges typical of VMC850, VMC1160, and VMC1580 models. Request documentation on static and dynamic rigidity tests, thermal compensation systems, and positioning accuracy (typically ±0.005mm). For high-precision applications, verify availability of 4-axis or 5-axis configurations with rotary tables and dual-nut ball screws.

Production Infrastructure Assessment

Evaluate supplier capacity using these benchmarks:

- Minimum factory area of 3,000m² to ensure stable production flow

- In-house assembly lines with vibration aging treatment for machine bases

- Dedicated quality inspection stations using laser interferometers and ballbar testers

Cross-reference online revenue indicators and reorder rates to assess market confidence. Prioritize suppliers with ≥90-day consistent on-time delivery records and response times under 3 hours.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services tied to shipment milestones. Require detailed pre-shipment inspection reports including no-load run tests, coolant system pressure checks, and tool changer cycle validation. Where possible, request video audits of final assembly stages to confirm build quality before dispatch. Sample orders are advisable for first-time engagements, especially when specifying non-standard features like extended Z-axis travel or high-speed spindles (≥10,000 RPM).

What Are the Leading LMW CNC Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shandong Yijin Cnc Machine Tool Co., Ltd. | Shandong, CN | Machining Centre (3,350), CNC Lathe (662) | $14,000–49,999 | 1 set | 100% | ≤1h | 50% | US $40,000+ |

| Jinan Taihe Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathe (152), Machining Centre (148) | $6,500–20,000 | 1 set | 100% | ≤1h | - | - |

| Jinan Hongda Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathe (715), Machining Centre (430) | $9,000–18,000 | 1 set | 100% | ≤1h | 30% | US $990,000+ |

| Shandong Mainland Cnc Equipment Co., Ltd | Shandong, CN | CNC Lathe (497), Manual Mills (326) | $11,300–46,000 | 1 set | 100% | ≤3h | 25% | US $180,000+ |

| Xiongyi Intelligent Machinery (Changzhou) Co., Ltd. | Jiangsu, CN | CNC Lathe (172), Machining Centre (81) | $12,300–40,000 | 1 set | 100% | ≤3h | <15% | US $10,000+ |

Performance Analysis

Shandong Yijin stands out with the highest reorder rate (50%) and broadest product range, indicating strong customer retention and technical versatility. Jinan Hongda demonstrates significant export volume (US $990,000+ online revenue), suggesting robust international distribution networks. All five suppliers maintain perfect on-time delivery records, but response efficiency varies—Shandong and Jinan-based firms consistently reply within one hour, enhancing communication agility for time-sensitive negotiations. Pricing reflects machine class differentiation: entry-level VMC850 models start at $6,500, while heavy-duty 4-axis VMC1580 systems exceed $45,000. Buyers should align budget parameters with structural integrity, spindle power (7.5kW–22kW), and control system brand (Syntec, Siemens, or Fanuc clones).

FAQs

How to verify LMW CNC machine supplier reliability?

Validate ISO 9001 certification status and request copies of equipment test certificates. Analyze supplier tags for reorder rate, response time, and delivery consistency. Conduct virtual factory tours to observe machining bed scraping processes, spindle mounting procedures, and final calibration workflows.

What is the typical lead time for CNC machine delivery?

Standard models require 30–45 days after deposit confirmation. Customized machines with multi-axis integration or special tool changers may extend to 60 days. Air freight is not viable due to weight; sea freight (FCL/LCL) remains standard, adding 15–25 days for Indian port clearance and inland transport to Coimbatore.

Do suppliers offer customization options?

Yes, most suppliers support tailored specifications including rapid traverse rates, ATC capacity (8–24 tools), CNC controller brands, and work envelope adjustments. Technical drawings and 3D models are typically provided within 72 hours for review prior to order confirmation.

Is onsite installation and training available?

Installation guidance is commonly included via instructional videos and manuals. Onsite technician deployment may incur additional fees. Buyers should confirm whether commissioning support covers leveling, dry-run diagnostics, and operator training modules.

Can I request a sample or test unit before bulk purchase?

Full-machine sampling is uncommon due to size and cost, but suppliers often allow remote live demonstrations via video call. Some offer trial units on consignment basis with refundable deposits, particularly for repeat customers or large-volume prospects.