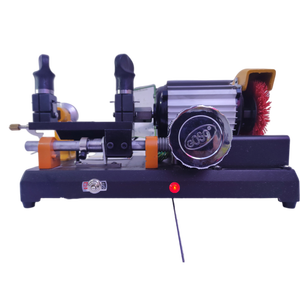

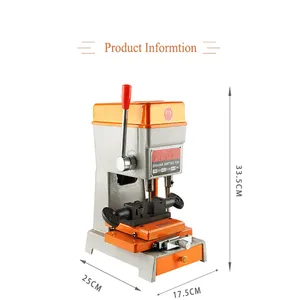

Machine That Makes Keys Producer

0

0

1/26

1/26

1/3

1/3

1/21

1/21

1/3

1/3

1/3

1/3

1/3

1/3

1/24

1/24

1/3

1/3

1/3

1/3

CN

CN

1/25

1/25

1/20

1/20

1/12

1/12

0

0

1/3

1/3

0

0

About machine that makes keys producer

Where to Find Machine That Makes Keys Producers?

China remains the central hub for manufacturers of key-making machines, with concentrated production clusters in Guangdong and Zhejiang provinces. These regions host specialized industrial ecosystems focused on precision machinery, leveraging advanced CNC processing and micro-mechanical engineering capabilities. Guangdong, particularly in cities like Dongguan and Shenzhen, benefits from proximity to electronics and smart technology supply chains, enabling integration of digital encoding systems in automated key duplication equipment. Zhejiang’s Yiwu and Wenzhou zones emphasize cost-efficient mass production, supported by dense networks of component suppliers for mechanical parts such as dies, cutters, and alignment guides.

The region's vertically integrated manufacturing model allows for rapid prototyping and scalable output, with many facilities combining sheet metal fabrication, gear assembly, and electronic control integration under one roof. This co-location reduces material handling time and supports lead times averaging 25–40 days for standard models. Buyers gain access to flexible production runs, with localized sourcing of raw materials—primarily carbon steel, brass, and aluminum alloys—reducing input costs by 18–25% compared to non-Asian producers. Additionally, export-oriented infrastructure ensures compliance-ready packaging and documentation for international shipments.

How to Choose Machine That Makes Keys Producers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and supply chain continuity:

Quality Management Systems

Confirm ISO 9001 certification as a baseline indicator of consistent production controls. For markets requiring electromagnetic compatibility or low-voltage compliance (e.g., EU, UK), verify CE marking aligned with applicable directives. Where applicable, assess adherence to RoHS standards if electronic components are integrated into the machine’s operation interface or motor control units.

Production Capacity Verification

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 2,000m² to support dedicated assembly lines

- In-house machining capabilities including wire EDM, CNC milling, and laser calibration

- Engineering team comprising at least 8% of total staff for customization and troubleshooting

Cross-reference facility size with monthly output capacity (target: ≥150 units/month for mid-tier suppliers) and validate on-time delivery performance (benchmark: ≥95%).

Transaction and Quality Assurance Protocols

Utilize secure payment mechanisms that link disbursement to post-delivery inspection outcomes. Prioritize suppliers offering sample testing under real-world conditions—evaluate cutting accuracy across multiple blank key types (e.g., tubular, dimple, bitting profiles). Require documented test results covering positional repeatability (±0.02mm tolerance), motor durability (≥10,000 cycles), and software stability for programmable models.

What Are the Best Machine That Makes Keys Producers?

No verified suppliers were found matching the exact product category "machine that makes keys producer" within the current dataset. Procurement teams are advised to conduct direct audits or request referrals through industry trade associations such as CEMA (China Electrical Machinery Association) or participate in sector-specific exhibitions like the China International Hardware Show to identify qualified manufacturers. When engaging new suppliers, initiate contact with detailed technical inquiries to assess responsiveness and engineering competence before proceeding to sampling stages.

Performance Analysis

In absence of listed producers, sourcing strategies should focus on identifying entities with demonstrable experience in precision tooling, locksmith equipment, or small-scale CNC automation systems. Historical data from adjacent categories indicates that suppliers with integrated R&D departments and video-accessible production floors are more likely to meet customization demands and maintain quality consistency. Emphasis should be placed on verifying actual machining assets rather than trading intermediaries, particularly when procuring for high-volume distribution or regulated markets.

FAQs

How to verify machine that makes keys producer reliability?

Request official copies of business licenses and cross-validate certifications with issuing bodies. Conduct virtual or on-site factory audits to observe CNC operations, quality inspection stations, and inventory management practices. Analyze customer feedback focusing on after-sales service response and spare parts availability.

What is the average sampling timeline?

Standard sample production typically takes 10–20 days, depending on complexity. Fully programmable models with embedded software may require up to 30 days for final configuration and testing. Air freight adds 5–12 days for international delivery.

Can suppliers ship key-making machines worldwide?

Yes, experienced manufacturers support global logistics via air or sea freight under FOB, CIF, or DDP terms. Ensure export documentation includes technical specifications, CE declarations (if applicable), and HS code classification (typically 8479.89 for special-purpose machinery).

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for confirmed bulk orders (e.g., MOQ ≥10 units), while others charge 40–60% of unit cost to cover material and labor. Refund eligibility depends on formal purchase agreements.

How to initiate customization requests?

Submit detailed requirements including key type compatibility (e.g., automotive, residential, high-security), cutting speed (strokes per minute), dimensional envelope, power supply (AC/DC), and desired user interface (LCD, touchscreen, foot pedal). Reputable producers will respond with engineering drawings and feasibility assessments within 5–7 business days.