Making Bows With A Bow Maker

About making bows with a bow maker

Where to Find Bow Making Machine Suppliers?

China leads global production of bow making machines, with key manufacturing clusters in Henan and Zhejiang provinces offering distinct competitive advantages. Henan is home to a concentrated network of machinery manufacturers specializing in semi-automatic and automatic ribbon bow equipment, supported by Zhengzhou’s advanced logistics infrastructure enabling rapid domestic and international shipment. Zhejiang, particularly Ningbo, hosts suppliers integrating electronic controls and precision engineering into high-speed automated systems, leveraging proximity to component suppliers for servo motors, tensioners, and programmable logic controllers (PLCs).

These regional ecosystems support vertically integrated production—spanning mechanical fabrication, electrical assembly, and final testing—allowing for scalable output and reduced lead times. Buyers benefit from localized supply chains that cut procurement cycles by 20–30% compared to offshore alternatives. Typical advantages include MOQs as low as one set for machine units, lead times ranging from 15–30 days for standard configurations, and strong customization capabilities in ribbon width (6–150mm), folding patterns, and material compatibility (satin, organza, fiberglass, and elastic ribbons).

How to Choose Bow Making Machine Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria focused on technical capability, quality assurance, and transactional reliability.

Technical Specifications & Production Capacity

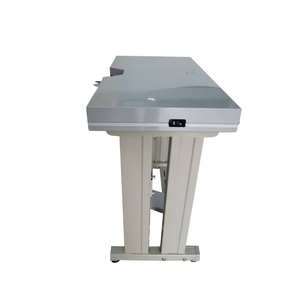

Verify machine type alignment: semi-automatic models typically range from $500–$800 per set, suitable for small-to-mid volume operations, while fully automatic systems can exceed $13,000 for high-output applications (e.g., gift packaging, floral decor). Confirm compatibility with target ribbon materials and widths. Evaluate factory infrastructure where available—suppliers with dedicated R&D teams and in-house CNC machining demonstrate greater adaptability for custom modifications.

Quality Management Systems

Prioritize suppliers demonstrating compliance with international standards. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 95% and response times under 6 hours serve as operational proxies for process discipline. Cross-reference performance metrics such as:

- On-time delivery ≥95%

- Reorder rate >30% indicating customer retention

- Average response time ≤3 hours

- Online transaction volume exceeding US $500,000 annually

Customization and Compliance Verification

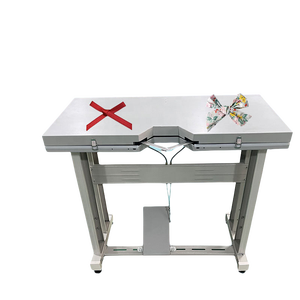

Assess customization depth beyond basic color or logo printing. Advanced suppliers offer adjustments in spindle count, rubber feeder width, bobbin size, and packaging integration. For export markets, ensure machines meet electrical safety standards applicable to destination regions. Request test reports or video demonstrations validating cycle time, knot consistency, and ribbon tension control.

Transaction Safeguards

Utilize secure payment methods with milestone-based releases. Conduct sample testing prior to full-scale orders—benchmark bow uniformity, ribbon waste rate, and mean time between failures (MTBF). Confirm after-sales support availability, including spare parts supply and remote troubleshooting assistance.

What Are the Best Bow Making Machine Suppliers?

| Company Name | Location | Product Range | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Automatic thread knotting, butterfly bow systems | $690–$9,214 | 1 set | 100.0% | ≤2h | US $1.4M+ | 44% |

| Ningbo Credit Ocean Machinery & Electron Co., Ltd. | Zhejiang, CN | Automatic Cricut-compatible, semi-auto satin ribbon | $540–$14,000 | 1 set | 97.0% | ≤6h | US $510K+ | 37% |

| Henan Kellen Machinery Equipment Co., Ltd. | Henan, CN | Semi-automatic, automatic tie-making | $490–$780 | 1 set | 95–96% | ≤3h | US $360K–$490K | <15% to 15% |

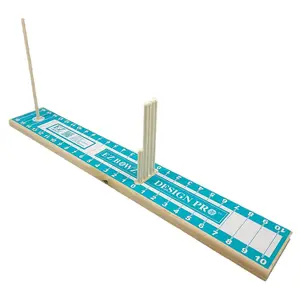

| Yiwu Billion Krypton E-Commerce Co., Ltd. | Zhejiang, CN | Wooden bow makers, handheld tools | $1.62–$8.80 per set | 300–1000 sets | 87.0% | ≤7h | US $270K+ | <15% |

Performance Analysis

Zhengzhou Zomagtc stands out with a 100% on-time delivery record and the highest reorder rate (44%), suggesting strong product reliability and service consistency. Ningbo Credit Ocean offers the broadest technical range, including high-end automatic systems compatible with precision crafting platforms, supported by extensive customization options across ribbon width, spindles, and feeding mechanisms. Henan Kellen provides competitively priced entry-level automation with fast response times, though lower reorder rates indicate potential gaps in long-term customer satisfaction. Yiwu Billion Krypton focuses on manual and tool-based solutions at ultra-low price points, targeting bulk buyers in seasonal decoration markets but exhibits lower delivery reliability.

FAQs

How to verify bow making machine supplier reliability?

Cross-check performance data such as on-time delivery, reorder rate, and response time against transaction history. Request machine operation videos or third-party inspection reports. Validate customization claims through prototype samples before scaling orders.

What is the average lead time for bow maker machines?

Standard models ship within 15–25 days after order confirmation. Customized units requiring PLC programming or special tooling may require 30–45 days. Air freight adds 5–10 days globally; sea freight ranges from 25–40 days depending on destination port.

Can suppliers accommodate OEM/ODM requests?

Yes, leading suppliers support OEM labeling, color branding, and packaging redesign. Higher-tier manufacturers also offer ODM services including modified folding mechanisms, dual-spindle configurations, and integrated cutting units. Minimum requirements typically start at 5 sets for customized electronics and 50+ units for branded enclosures.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers offer functional machine demos at partial cost recovery ($100–$500), which may be credited toward first orders. Disposable bow tool samples (wooden/fiberglass) are often provided free for bulk commitments (≥1,000 sets).

How to initiate customization for ribbon bow machines?

Submit detailed specifications including ribbon material type, width (in mm), desired bow style (cluster, spiral, fan-fold), output speed (bows/minute), and power supply (110V/220V, single/three-phase). Reputable suppliers respond with technical drawings or 3D renderings within 72 hours and deliver prototypes in 3–5 weeks.