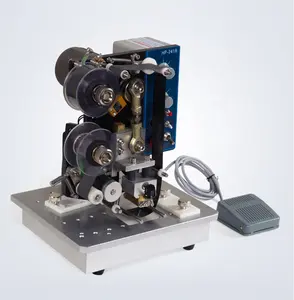

Manual Ribbon Coding Machine

1/20

1/20

1/16

1/16

1/9

1/9

1/32

1/32

1/11

1/11

1/21

1/21

About manual ribbon coding machine

Where to Find Manual Ribbon Coding Machine Suppliers?

China serves as the central hub for manual ribbon coding machine manufacturing, with key production clusters concentrated in Zhejiang, Henan, and Guangdong provinces. These regions host vertically integrated supply chains that streamline component sourcing—particularly for dies, hot stamping foils, and mechanical molds—enabling rapid assembly and cost-efficient production. Wenzhou in Zhejiang specializes in precision hand-operated coding equipment, leveraging decades of expertise in packaging machinery to deliver robust, low-maintenance devices suitable for small to mid-volume operations.

The industrial ecosystems support agile manufacturing models, where suppliers maintain in-house tooling, die-cutting, and assembly lines within compact geographic zones. This integration reduces lead times to 15–25 days for standard orders and allows flexibility for minor customizations, such as date format configurations or multi-line stamping dies. Buyers benefit from localized access to raw materials like aluminum-alloy housings and high-temperature-resistant ribbons, which contribute to a 20–30% cost advantage over equivalent machines produced outside Asia.

How to Choose Manual Ribbon Coding Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify that suppliers adhere to internationally recognized quality frameworks. While ISO 9001 certification is not universally present among smaller manufacturers, it should be prioritized for high-volume procurement. Machines intended for export to regulated markets must comply with CE marking requirements for mechanical safety. Request documentation on material durability, including resistance testing for stamping heads under repeated thermal stress.

Production Capability Assessment

Evaluate supplier infrastructure based on the following indicators:

- Minimum facility size supporting dedicated assembly and quality inspection zones

- In-house die-making or mold fabrication capabilities for customized numbering wheels

- Integration of packaging subsystems (e.g., ribbon feed mechanisms, tension control)

Cross-reference performance metrics: target on-time delivery rates exceeding 90% and reorder rates above 25% as proxies for product reliability and customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment methods with escrow functionality to ensure product conformity prior to release of funds. Prioritize suppliers with verifiable online transaction histories and documented after-sales service protocols. Conduct sample testing to assess print clarity, alignment consistency, and ribbon consumption efficiency before scaling orders.

What Are the Best Manual Ribbon Coding Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Jiaozuo Yuanlai Trading Co., Ltd. | Capping, Filling, Sealing, Labeling Machines | US $50,000+ | 94% | 15% | ≤2h | 5 models | $40/set |

| Wenzhou Haizhou Import And Export Co., Ltd. | Custom Manufacturer – Packaging Equipment | US $950,000+ | 99% | <15% | ≤2h | 3 models | $25–48/set |

| Dongguan Sammi Packing Machine Co., Ltd. | Packaging, Filling, Sealing, Labeling Machines | US $50,000+ | 90% | 27% | ≤2h | 5 models | $108–126/set |

| Xinxiang Fineray Tech Co., Ltd. | Printer Ribbons, Inks, Stamping Foil | US $70,000+ | 89% | 22% | ≤6h | 5 listings | $0.40–$160 |

| Shanghai Demac Machinery Equipment Co., Ltd. | Coding Machines, Inkjet Printers, Printer Ribbons | US $80,000+ | 100% | 42% | ≤6h | 5 models | $45–1,980 |

Performance Analysis

Wenzhou Haizhou stands out for its high-volume export capacity and competitive pricing, with models starting at $25 per set, making it ideal for budget-sensitive buyers. Despite a lower reorder rate, its 99% on-time delivery performance indicates strong logistics execution. Shanghai Demac demonstrates exceptional customer retention (42% reorder rate), suggesting high satisfaction with build quality and technical support. Dongguan Sammi offers premium-priced units ($108–126) with consistent pricing, reflecting specialization in durable, multi-use applications. Jiaozuo Yuanlai provides entry-level DY-8 series machines at $40/set, suitable for startups or intermittent use. Xinxiang Fineray, while offering consumables like replacement ribbons at scale ($0.40/piece, MOQ 100), positions itself as a component supplier rather than a full-machine manufacturer.

FAQs

What is the typical minimum order quantity (MOQ)?

Most suppliers list an MOQ of 1 set for initial trials, allowing buyers to evaluate machine performance before committing to bulk purchases. Ribbon consumables may require higher MOQs, such as 100 pieces or more.

What are common customization options?

Buyers can request modifications to date formats (DD/MM/YYYY, MM/YY, etc.), add batch numbers or logos, and specify font sizes. Some suppliers offer multi-line dies or interchangeable numbering wheels. Confirm compatibility with substrate types (plastic film, paper, foil) during customization discussions.

What is the average lead time for delivery?

Standard orders typically ship within 15–20 days after payment confirmation. Custom configurations involving specialized dies or branding elements may extend lead times to 30 days. Air freight adds 7–10 days for international delivery.

Do suppliers provide machine operation training or manuals?

Yes, most suppliers include basic user guides in English. High-reorder-rate vendors like Shanghai Demac often provide instructional videos or remote support for setup and troubleshooting. Clarify language accessibility of documentation before ordering.

Are spare parts and consumables readily available?

Replacement ribbons, numbering wheels, and spring components are generally available from the same supplier. Companies like Xinxiang Fineray specialize in consumables, ensuring long-term supply continuity. Confirm availability of wear-prone parts to minimize machine downtime.