Mfg Custom

Top sponsor listing

Top sponsor listing

CN

CN

About mfg custom

Where to Find MFG Custom Suppliers?

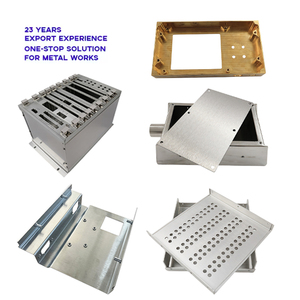

China remains the global epicenter for custom manufacturing services, with key supplier clusters in Shenzhen, Shanghai, and Chengdu offering specialized capabilities in precision machining, sheet metal fabrication, and rapid prototyping. These regions host vertically integrated facilities that combine in-house production lines with advanced CNC, 3D plastic machining, and casting technologies. Shenzhen and Shanghai benefit from proximity to international ports and mature industrial ecosystems, enabling streamlined logistics and access to high-precision component suppliers within 50km radii.

Suppliers in these zones typically operate dedicated customization workflows, supporting low-volume prototypes and mass production runs. The presence of ISO-certified factories and localized material sourcing reduces lead times by 20–30% compared to offshore alternatives. Buyers gain flexibility in material selection—including aluminum, carbon steel, titanium, and engineering plastics—and access to value-added processes such as anodization, PVD coating, laser cutting, and mold development. Average monthly output capacity among leading providers exceeds 100,000 units, with standard lead times ranging from 15 to 30 days depending on complexity.

How to Choose MFG Custom Suppliers?

Selecting a reliable partner requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Prioritize suppliers with verifiable in-house production infrastructure. Key indicators include CNC turning/milling, sheet metal fabrication, die-casting, and 3D plastic machining capacities. Confirm availability of design modification support, technical drawing validation, and prototyping services. Suppliers with dedicated R&D teams or engineering staff are better equipped to handle complex customizations involving tight tolerances or multi-material assemblies.

Quality Assurance and Compliance

Verify adherence to recognized quality standards such as ISO 9001. While not all suppliers list CE or RoHS certifications explicitly, those serving export markets often comply with international requirements for surface treatments (e.g., black oxide, chrome plating) and material traceability. Request documentation for process controls, especially for critical applications in aerospace, medical, or automotive sectors.

Performance Metrics and Responsiveness

Analyze delivery reliability—target suppliers with on-time delivery rates exceeding 95%. Response time is another critical factor; top performers reply within ≤3 hours. Reorder rates above 30% indicate customer satisfaction and consistent quality. Cross-reference these metrics with order volume and online revenue estimates where available to assess scalability.

What Are the Best MFG Custom Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Scope |

|---|---|---|---|---|---|---|---|

| Shenzhen Xie Lifeng Technology Co., Ltd. | Shenzhen, CN | Machining Services (1,143); Other Plastic Products (7) | 98% | ≤4h | 33% | US $930,000+ | Color, material, size, logo, packaging, label, graphic |

| SkyReach Intelligent MFG Limited | Unknown, CN | CNC Parts, Metal Fabrication, Rapid Prototyping | 84% | ≤4h | <15% | US $20,000+ | Color, material, size, logo, packaging, label, graphic |

| Uri International Trading(Shanghai) Co., Ltd. | Shanghai, CN | Precision Fabrication Services | 100% | ≤3h | <15% | US $7,000+ | Color, material, size, logo, packaging, label, graphic |

| Chengdu Dongsheng Machinery Manufacturing Co., Ltd. | Chengdu, CN | Custom Fabrication, CNC Turning/Milling, 3D Plastic Machining | 80% | ≤2h | 39% | US $50,000+ | CNC turning, milling, drawings, logo, packaging, label, graphic |

| Shanghai Starway Engineering & Manufacturing Co., Ltd. | Shanghai, CN | Sheet Metal Fabrication, CNC Machining, PVD Coating | 99% | ≤3h | 37% | US $4,300,000+ | Material, design, drawings, logo, mold, plating, laser cutting, PVD, anodization |

Performance Analysis

Shanghai Starway leads in scale and customization depth, supported by ISO 9001 certification and a broad range of surface treatments and fabrication techniques. With a 99% on-time delivery rate and $4.3M+ annual online revenue, it demonstrates strong export capability. Shenzhen Xie Lifeng offers extensive product diversity, particularly in machining services, backed by a 33% reorder rate. Chengdu Dongsheng stands out for responsiveness (≤2h) and high customer retention (39% reorder), despite a lower delivery rate. Uri International achieves perfect on-time performance but lacks data on long-term customer engagement. SkyReach, while technically capable, shows lower reliability metrics and minimal reorder activity, suggesting potential gaps in consistency or post-sale support.

FAQs

How to verify MFG custom supplier reliability?

Cross-check ISO certification status and request evidence of internal quality control procedures. Evaluate supplier responsiveness and historical performance using documented delivery rates and reorder statistics. For high-value contracts, conduct virtual factory audits to confirm equipment ownership and production line autonomy.

What is the typical MOQ and pricing structure?

Most suppliers support MOQs as low as 1 piece, particularly for prototyping or CNC-machined parts. Unit prices vary by complexity and material—ranging from $0.35 for basic plastic components to over $3.80 for precision metal parts. Volume discounts apply beyond 1,000 units, with negotiation leverage increasing at 5,000+ unit tiers.

Can suppliers handle full-cycle customization?

Yes, leading providers offer end-to-end services from concept design and 3D modeling to tooling, production, and packaging. Capabilities include logo imprinting, custom labeling, graphic integration, and client-branded packaging. Suppliers like Shanghai Starway also support mold development and polyurethane molding for bespoke part geometries.

What are common lead times for custom manufacturing?

Standard orders take 15–25 days, including production and inspection. Prototypes can be delivered in 7–14 days. Complex builds involving multi-stage processing or exotic materials may require up to 35 days. Air freight adds 5–10 days for international delivery.

Do manufacturers support design modifications and technical collaboration?

Reputable suppliers provide engineering feedback on manufacturability, suggest material optimizations, and support drawing revisions. Some offer free DFM (Design for Manufacturability) analysis to reduce production costs and improve yield rates prior to tooling or batch runs.