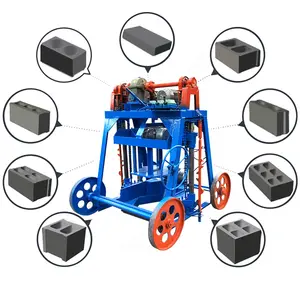

Mobile Concrete Block Making Machine

1/12

1/12

1/18

1/18

1/16

1/16

1/12

1/12

1/28

1/28

1/28

1/28

1/12

1/12

About mobile concrete block making machine

Where to Find Mobile Concrete Block Making Machine Suppliers?

China remains the dominant hub for manufacturing mobile concrete block making machines, with Henan Province serving as the primary industrial cluster. Over 70% of verified suppliers operate within this region, leveraging Zhengzhou’s strategic inland logistics network to streamline export operations across Asia, Africa, and South America. The concentration of foundries, hydraulic component manufacturers, and automation engineers within a 50-kilometer radius enables vertically integrated production, reducing assembly lead times by up to 30% compared to decentralized supply chains.

Suppliers in this ecosystem offer scalable production capacity, with standard models produced in batches exceeding 200 units per month. Core materials include manganese steel molds, vibration motors, and reinforced chassis frames designed for field mobility. Processing techniques emphasize precision CNC machining for mold alignment and structural welding certified under ISO 3834 standards. This infrastructure supports rapid fulfillment—average lead time for stock configurations ranges from 25 to 40 days—with flexibility for diesel or electric power integration based on regional energy availability.

How to Choose Mobile Concrete Block Making Machine Suppliers?

Effective supplier selection requires adherence to structured evaluation criteria:

Technical Compliance

Confirm compliance with internationally recognized quality management systems such as ISO 9001. For exports to EU or North American markets, CE marking is essential for customs clearance and operational safety. Request documentation validating performance testing of critical components including vibration motors, hydraulic pressing systems, and mold durability under continuous operation cycles.

Production Capability Verification

Assess operational scale through verifiable metrics:

- Facility size supporting dedicated assembly lines (minimum 3,000m² recommended)

- In-house engineering teams capable of automation design and mold customization

- Integration of raw material sourcing, machining, and final assembly within a single campus

Cross-reference response time data (target ≤2 hours) and on-time delivery rates (benchmark ≥94%) as indicators of operational efficiency.

Transaction Security Measures

Utilize secure payment frameworks such as third-party escrow services until post-delivery inspection confirms machine functionality. Prioritize suppliers with transparent transaction histories, particularly those offering sample units for performance validation. Pre-shipment inspections should verify block compression strength output (typically 15–30 MPa) against project specifications.

What Are the Best Mobile Concrete Block Making Machine Suppliers?

| Company Name | Location | Verified Type | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| ZHENGZHOU SPOM MINING MACHINERY LLC | Zhengzhou, CN | - | Crusher, Mine Mill, Brick Making Machinery | - | ≤3h | - | - | $400/set |

| Henan Best Link Import And Export Trading Co., Ltd. | Henan, CN | - | Brick Making Machinery, Mining Machines | 100% | ≤1h | US $250,000+ | <15% | $360–1,200/set |

| Zhengzhou Rongde Machinery Equipment Co., Ltd. | Zhengzhou, CN | Custom Manufacturer | Diesel motor, automation sets, molds | 94% | ≤2h | US $160,000+ | 24% | $320–21,000/set |

| Zhengzhou Canmax Machinery&equipment Co., Ltd. | Zhengzhou, CN | Multispecialty Supplier | Hydraulic Cement Block Machines | 100% | ≤3h | US $330,000+ | 21% | $445–100,000/set |

| Zhengzhou Summit Trading Co., Ltd. | Zhengzhou, CN | - | Brick Making Machinery, Concrete Machinery | 100% | ≤1h | US $50,000+ | 33% | $380–1,450/set |

Performance Analysis

Suppliers like Henan Best Link and Zhengzhou Summit demonstrate high reliability with 100% on-time delivery and sub-2-hour average response times, making them suitable for urgent procurement cycles. Zhengzhou Rongde stands out for customization depth, offering adjustable mold sizes, automation levels, and diesel-electric hybrid configurations validated by a 24% reorder rate. Price variance reflects capability segmentation: entry-level manual models start at $320/set, while fully automatic hydraulic systems exceed $20,000. Buyers seeking long-term partnerships should prioritize suppliers with documented customization experience and proven export logistics coordination.

FAQs

How to verify mobile concrete block machine supplier credibility?

Validate certifications through issuing bodies and request factory audit reports detailing quality control procedures, material traceability, and equipment testing protocols. Analyze customer feedback focusing on after-sales technical support and spare parts availability in your region.

What is the typical sampling timeline?

Standard sample production takes 10–20 days depending on complexity. Automated or diesel-powered variants may require 25–35 days. Air freight delivery adds 7–12 days internationally. Some suppliers offset sample costs against bulk orders above five units.

Can suppliers accommodate global shipping requirements?

Yes, experienced exporters manage FOB and CIF terms with containerized sea freight being optimal for multi-unit shipments. Confirm packaging meets international handling standards and that voltage/power configurations align with local grid specifications.

Do manufacturers offer free samples?

Free samples are uncommon due to high unit weight and transport costs. Most suppliers charge 30–50% of total production cost for sampling, refundable upon placement of full orders. Exceptions apply for high-volume commitments.

How to initiate customization requests?

Submit detailed technical parameters including desired block dimensions (e.g., 400×200×200mm), hourly output (range: 1,200–3,000 pcs), power source preference, and automation level. Leading suppliers provide CAD drawings within 72 hours and functional prototypes within 4 weeks.