Momos Making Machine Fully Automatic

Top sponsor listing

Top sponsor listing

About momos making machine fully automatic

Where to Find Momos Making Machine Fully Automatic Suppliers?

China leads global production of fully automatic momos making machines, with key manufacturing clusters in Henan and Shandong provinces. These regions host vertically integrated supply chains specializing in food processing equipment, enabling competitive pricing and rapid scalability. Henan accounts for over 50% of China’s grain product making machinery suppliers, supported by mature ecosystems for electromechanical components and industrial automation systems. Shandong complements this with strong metal fabrication and CNC machining infrastructure, reducing lead times for precision-critical parts such as molds and filling mechanisms.

Suppliers in these hubs operate facilities ranging from 1,000 to 25,000+ m², integrating R&D, casting, assembly, and testing under one roof. This localization reduces component procurement time by up to 40% compared to offshore alternatives. Buyers benefit from MOQs as low as 1 set, average lead times of 15–30 days for standard models, and access to customization options including output capacity (500–6,000 pcs/h), voltage (110V/220V), and mold design for regional dumpling shapes (half-moon, crescent, round). The concentration of engineering talent—particularly in Luohe and Zhengzhou—further enhances technical responsiveness and after-sales support efficiency.

How to Choose Momos Making Machine Fully Automatic Suppliers?

Effective supplier selection requires a structured evaluation across three core dimensions:

Technical Compliance & Design Capability

Verify that suppliers offer machines compliant with international electrical safety standards (CE certification preferred). Confirm availability of critical technical documentation, including motor specifications (power: 0.75–3kW), material certifications for food-contact surfaces (SUS304 stainless steel), and control system details (PLC or microcomputer-based). For high-volume buyers, prioritize vendors with in-house mold design teams capable of customizing size, weight, and sealing patterns based on regional preferences.

Production Capacity & Operational Reliability

Assess operational scale through verifiable metrics:

- Facility size exceeding 2,000m² indicates capacity for batch production

- In-house machining capabilities ensure consistency in mold tolerances (±0.1mm)

- Dedicated quality inspection lines with pre-shipment testing protocols

Cross-reference on-time delivery rates (target ≥97%) and reorder rates (ideally >20%) as indicators of reliability and customer satisfaction.

Transaction Security & After-Sales Support

Favor suppliers offering secure transaction channels and documented service frameworks. Evaluate response time (≤2 hours is optimal) and language proficiency for smoother communication. Confirm availability of remote troubleshooting support, spare parts inventory, and field engineer dispatch options. Request sample units to validate performance against benchmarks such as dough feeding accuracy, filling consistency, and seal integrity before full-scale ordering.

What Are the Best Momos Making Machine Fully Automatic Suppliers?

| Company Name | Location | Verified Status | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Luohe Quality Mechanical Equipment Co., Ltd. | Henan, CN | Custom Manufacturer | Grain Product Making Machines, Baozi/Momo Machines | 97% | 20% | ≤2h | US $1,000,000+ | Output, diameter, shape, size, mold, weight, capacity |

| Henan Finer Electromechanical Equipment Co., Ltd. | Henan, CN | Grain Product Making Machines, Filling Machines | 91% | 25% | ≤1h | US $240,000+ | ||

| Saidashi Machinery (Henan) Co., Ltd. | Henan, CN | Grain Product Making Machines, Empanada/Ravioli Machines | 100% | 20% | ≤3h | US $100,000+ | ||

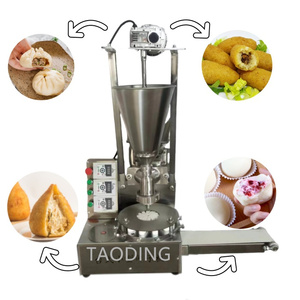

| Jiaozuo Taoding Trading Co., Ltd. | Henan, CN | Multispecialty Supplier | Grain Product Making Machines, Meat Slicers | 97% | 15% | ≤2h | US $540,000+ | Color, shape, thickness, pattern, mold, cable, speed |

| Shandong Meiying Food Machinery Co., Ltd. | Shandong, CN | Grain Product Making Machines, Dough Mixers | 50% | <15% | ≤2h | US $2,000+ |

Performance Analysis

Luohe Quality Mechanical Equipment stands out with the highest online revenue (US $1M+) and robust customization capabilities, making it ideal for buyers requiring tailored solutions. Saidashi Machinery achieves perfect on-time delivery (100%), indicating strong internal logistics control despite lower revenue volume. Henan Finer Electromechanical ranks high in customer retention (25% reorder rate) and fast response times (≤1h), suggesting efficient sales and technical support operations. Jiaozuo Taoding offers broad customization across mechanical and aesthetic parameters, suitable for branded or region-specific deployments. Shandong Meiying, while technically active, shows lower reorder rates and delivery performance, indicating potential scalability or quality control limitations.

FAQs

How to verify momos making machine supplier reliability?

Cross-check declared certifications (e.g., CE, ISO) with official registries. Request factory audit reports or video walkthroughs to confirm production lines and quality checks. Analyze transaction history, focusing on consistent on-time delivery (>95%) and repeat buyer activity (reorder rate >20%).

What is the typical sampling timeline?

Standard samples take 7–15 days to produce. Customized configurations involving new molds or voltage adaptations require 20–30 days. Air shipping adds 5–10 days depending on destination.

Can suppliers ship globally?

Yes, most established manufacturers support international shipping via air or sea freight. Confirm Incoterms (FOB, CIF), packaging standards for long-haul transport, and compliance with local electrical and food safety regulations at the destination.

Do suppliers offer free samples?

Free samples are uncommon due to unit costs ($500–$1,800). Some vendors offset sample fees against future bulk orders (typically 5+ units). Buyers should expect to cover shipping and import duties for trial units.

How to initiate customization requests?

Submit detailed requirements including desired output (pcs/h), dough and filling types, final product dimensions, power supply specs, and material preferences. Leading suppliers provide CAD drawings or 3D renderings within 3–5 business days and can develop functional prototypes within 4 weeks.