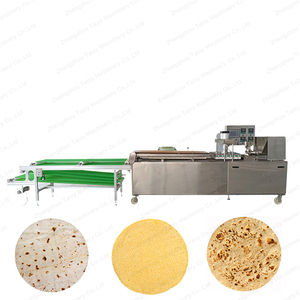

Parotta Making Machine Fully Automatic

1/8

1/8

1/4

1/4

CN

CN

1/18

1/18

1/16

1/16

About parotta making machine fully automatic

Where to Find Parotta Making Machine Suppliers?

China remains the dominant manufacturing hub for fully automatic parotta making machines, with key production clusters located in Shandong and Henan provinces. These regions host vertically integrated food machinery ecosystems, combining precision engineering, stainless steel fabrication, and automated control systems under one supply chain. Shandong, particularly Jinan and Qingdao, specializes in industrial-scale bakery equipment, leveraging proximity to port infrastructure for efficient global export. Henan’s Zhengzhou corridor supports high-volume component sourcing, reducing lead times by 15–20% compared to non-specialized regions.

The concentration of grain processing machinery manufacturers enables rapid prototyping and scalable production. Suppliers benefit from localized access to servo motors, PLC controllers, and food-grade stainless steel, ensuring consistent build quality. Buyers gain flexibility in output capacity—from compact units producing 600 pieces per hour to full production lines exceeding 3,000 units per hour. The ecosystem supports both standardized models and engineered solutions for multi-layered or stuffed parotta variants.

How to Choose Parotta Making Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international food safety standards, including CE marking for electrical systems and compliance with ISO 22000 for food contact surfaces. Machines should feature IP-rated enclosures (minimum IP54) to resist moisture and flour dust. Confirm integration of PID temperature controls, adjustable rolling mechanisms, and flame supervision systems for gas-powered models.

Production Capability Audits

Assess core manufacturing competencies through verifiable metrics:

- Minimum factory area of 3,000m² indicating industrial-scale operations

- In-house R&D teams capable of customizing dough feeding, pressing, and baking zones

- Stainless steel fabrication and welding capabilities for hygienic construction

Cross-reference on-time delivery rates (>94%) and response times (≤2 hours) as proxies for operational reliability.

Transaction Safeguards

Utilize secure payment methods such as escrow services until post-delivery inspection. Prioritize suppliers with documented quality control procedures, including pre-shipment testing of cycle time, yield consistency, and energy consumption. Request video demonstrations of machine operation and validation reports for customized configurations.

What Are the Best Parotta Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Min. Order Value | Customization |

|---|---|---|---|---|---|---|---|---|

| Qixian Xincheng E-Commerce Co., Ltd. | Henan, CN | US $4,000+ | 100% | ≤1h | <15% | Roti, Chapati, Tortilla | $323.40/dozen | Limited |

| Adan Trading Inc | Shandong, CN | Not disclosed | Not available | ≤2h | Not available | Pita, Paratha, Arabic Bread | $3,200/set | Moderate |

| Shanghai Yingzhen Food Machinery Co., Ltd. | Shanghai, CN | US $810,000+ | 94% | ≤2h | 26% | Stuffed Paratha, Multi-Layer Roti | $15,000/set | High |

| Jinan FLD Machinery CO.,LTD | Shandong, CN | US $70,000+ | 100% | ≤1h | 16% | Pasta, Macaroni (cross-category) | $8,000/set | Extensive |

| Parmat Automation Equipment (Jinan) Co., Ltd. | Shandong, CN | US $70,000+ | 100% | ≤1h | <15% | Dry Pasta, Elbow Macaroni | $7,000/set | High (up to 500kg/h) |

Performance Analysis

Shanghai Yingzhen stands out with the highest online revenue (US $810,000+) and proven capability in multi-functional parotta lines, including cheese-stuffed and lacha paratha variants. Despite a slightly lower on-time delivery rate (94%), its 26% reorder rate indicates strong customer retention. Qixian Xincheng offers entry-level automation at competitive pricing ($323.40 per dozen), suitable for small bakeries, though customization options are limited. Parmat Automation and Jinan FLD specialize in high-capacity extrusion and drying systems, with Parmat offering a 500kg/h customizable pasta line—indicative of advanced process engineering applicable to flatbread automation. All top-tier suppliers maintain sub-2-hour response times, with 100% on-time delivery recorded for three companies, signaling robust order management systems.

FAQs

What certifications should parotta making machine suppliers have?

Ideal suppliers hold ISO 9001 for quality management and CE certification for electrical safety. For export to Europe or North America, compliance with IEC 60204-1 (safety of machinery) and hygiene standards like EHEDG is recommended. Verify documentation for motor efficiency, control panel ratings, and material traceability.

What is the typical lead time for fully automatic parotta machines?

Standard models require 20–30 days for production and packaging. Customized production lines, especially those integrating fermentation or stacking units, may take 45–60 days. Shipping via sea freight adds 25–40 days depending on destination.

Can suppliers provide OEM/ODM services?

Yes, established manufacturers offer OEM branding and ODM engineering. Capabilities include logo integration, voltage adaptation (110V/220V/380V), and modifications to dough thickness, cooking temperature, and throughput. Suppliers like Jinan FLD and Parmat Automation explicitly list multi-layer tunnel drying and color material customization.

What are common MOQs and pricing tiers?

Entry-level units start at $323.40 per dozen (small batch), while industrial sets range from $3,200 to $48,000. High-output production lines exceed $500,000. Most suppliers set MOQ at 1 set for full machines, enabling pilot procurement. Bulk orders often unlock firmware upgrades or spare part packages.

How to validate machine performance before purchase?

Request live video testing showing dough intake, sheeting consistency, and final product ejection. Ask for sample production logs including power consumption (kW/h), rejection rate, and hourly output. For critical deployments, commission third-party inspection agencies like SGS or Bureau Veritas to conduct pre-shipment audits.