Most Advanced Cnc Machine In The World

CN

CN

CN

CN

About most advanced cnc machine in the world

Where to Find Suppliers of the Most Advanced CNC Machines?

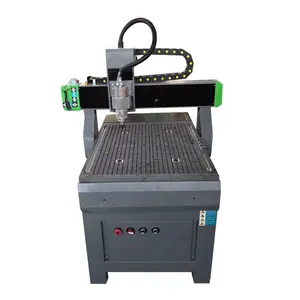

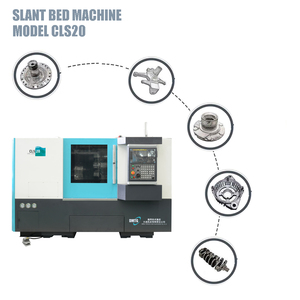

China remains a global leader in advanced CNC machine manufacturing, with key industrial hubs concentrated in Shandong, Jiangsu, and Guangdong provinces. These regions host vertically integrated production ecosystems that combine precision engineering, automated assembly lines, and robust supply chains for critical components such as servo motors, ball screws, and digital control systems. Shandong’s Jinan cluster specializes in woodworking CNC routers with high-speed spindles and automatic tool changers, while Jiangsu excels in multi-axis metal-cutting centers, including 5-axis milling and wire EDM machines designed for aerospace and mold-making applications.

The geographic concentration enables suppliers to achieve economies of scale, reducing component lead times and enabling rapid prototyping. Facilities typically operate within co-located supplier networks—providing access to castings, linear guides, and electronic controls within 50 km—supporting shorter delivery cycles (average 30–45 days for standard configurations). Buyers benefit from competitive pricing structures, with production cost advantages of 20–35% over European or North American manufacturers, particularly for customized or mid-volume orders.

How to Choose Suppliers of the Most Advanced CNC Machines?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm integration of advanced features such as automatic lubrication systems, vacuum workholding, angle heads, and digital control interfaces. For high-precision applications, verify spindle runout tolerances (≤0.005 mm), positioning accuracy (±0.01 mm), and use of hardened linear ways or THK/Hiwin rails. Suppliers serving automotive or medical sectors should demonstrate compliance with ISO 9001 standards; CE marking is essential for EU market access and indicates adherence to electromagnetic compatibility and machinery safety directives.

Production Infrastructure Assessment

Evaluate core manufacturing capacity through objective metrics:

- Minimum factory area exceeding 3,000m² to support full-cycle production

- In-house machining capabilities for base casting finishing and gantry alignment

- Dedicated R&D teams focused on motion control optimization and HMI integration

Cross-reference supplier claims with verifiable performance data, including on-time delivery rates (>97%) and reorder frequency, to assess reliability and customer satisfaction.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure funds are released only after equipment verification. Prioritize suppliers offering sample testing or remote factory audits via video inspection. Request detailed documentation on spindle power ratings, drive systems (servo vs. stepper), and tool changer cycle times before finalizing procurement. For international shipments, clarify FOB/CIF terms and confirm packaging standards suitable for ocean freight to prevent transit damage.

What Are the Leading Suppliers of the Most Advanced CNC Machines?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Key Features Offered |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Minnuo Group Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $6,800,000+ | 100.0% | ≤2h | 50% | 5 models | 5-axis tables, automatic tool changers, servo-driven systems |

| Jinan Bcamcnc Machinery Co., Ltd. | Shandong, CN | Brand Holder | US $1,800,000+ | 100.0% | ≤2h | 31% | 5 models | Double dust collectors, air-cooled spindles, four-axis control |

| Jiangsu Index Intelligent Equipment Co., Ltd. | Jiangsu, CN | Custom Manufacturer | Not disclosed | 100.0% | ≤2h | - | 5 models | High-precision VMC series, intelligent control systems |

| Foshan Sds Smart Tech Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $410,000+ | 100.0% | ≤2h | 25% | 5 models | Carbide-compatible vertical machining, fast cycle times |

| Jinan Smart Technology Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $350,000+ | 100.0% | ≤2h | 50% | 5 models | Aluminum profile processing, single-spindle molding |

Performance Analysis

Jiangsu Minnuo Group stands out with the highest reported online revenue and a 50% reorder rate, indicating strong customer retention and scalable production infrastructure. The company offers 5-axis technology and large-format gantry mills suited for complex aerospace and die-molding tasks. Jinan Bcamcnc distinguishes itself as a brand holder with comprehensive feature sets—including dual dust extraction and automatic knife systems—targeting high-throughput woodworking operations. Foshan Sds Smart Tech provides high-precision vertical machining centers capable of carbide and hardened steel processing, appealing to tool and die manufacturers requiring micron-level repeatability. All top-tier suppliers maintain 100% on-time delivery records and sub-2-hour response times, underscoring operational efficiency. Buyers seeking customization should prioritize manufacturers advertising in-house design teams and flexible configuration options for control systems, motor types, and workspace dimensions.

FAQs

How to verify the technical specifications of an advanced CNC machine?

Request detailed datasheets covering spindle speed range (e.g., 18,000–24,000 RPM), motor power (≥7.5 kW for heavy cutting), table size, and control system type (Syntec, Mach3, or Siemens). Validate claims through video demonstrations of live cutting tests and review third-party inspection reports when available.

What is the typical minimum order quantity (MOQ) and lead time?

Standard MOQ is 1 set, allowing buyers to test machine performance before scaling procurement. Lead times average 30 days for stock configurations; custom builds with specialized tool changers or extended work envelopes may require 45–60 days.

Can suppliers customize CNC machines for specific materials?

Yes, leading manufacturers offer material-specific tuning for wood, aluminum, composites, or hardened steels. Customizations include variable frequency drives, high-torque gear transmission, and adaptive cooling systems. Confirm compatibility with your target feed rates and depth-of-cut requirements during consultation.

Do suppliers provide installation and training support?

Most offer remote setup guidance via video call. Some provide on-site technician deployment at additional cost, particularly for 5-axis or automated cell integrations. Training typically covers G-code programming basics, tool calibration, and preventive maintenance routines.

Are there export restrictions on advanced CNC equipment?

Certain high-precision models (e.g., sub-micron tolerance machines) may fall under dual-use technology regulations depending on destination country. Buyers should confirm export compliance status and obtain necessary import permits prior to shipment.