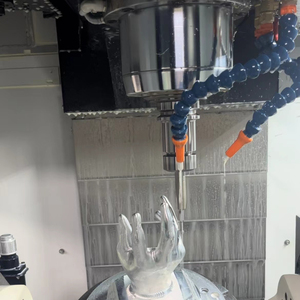

Multi Axis Machining

About multi axis machining

Where to Find Multi Axis Machining Equipment Suppliers?

China remains the dominant hub for multi-axis machining equipment manufacturing, with key industrial clusters in Guangdong, Shandong, and Jiangsu provinces driving innovation and scale. Dongguan and Jinan serve as core production centers, hosting vertically integrated facilities that combine CNC component fabrication, assembly, and precision testing under one roof. These regions benefit from mature supply chains for linear guides, spindles, and control systems, reducing lead times by 20–30% compared to non-specialized manufacturers.

The concentration of technical expertise enables rapid prototyping and customization, particularly for 4-axis and 5-axis CNC routers and machining centers. Suppliers in these zones typically operate automated production lines capable of monthly outputs ranging from 50 to 200 units, depending on machine complexity. Buyers gain access to ecosystems where engineering support, after-sales service networks, and export logistics are co-located, facilitating faster deployment and integration into downstream manufacturing workflows.

How to Choose Multi Axis Machining Equipment Suppliers?

Effective supplier selection requires a structured evaluation across three critical dimensions:

Technical Capability Verification

Confirm that suppliers offer documented specifications for axis configuration (e.g., 3+2 or full 5-axis simultaneous), spindle power (ranging from 7.5kW to 18kW in premium models), and positional accuracy (typically ±0.01mm). For metal-cutting applications, verify use of hardened cast iron beds and high-torque servo motors. Wood and composite-focused systems should include dust extraction integration and ATC (Automatic Tool Changer) compatibility.

Production Infrastructure Assessment

Evaluate operational scale through objective indicators:

- Facility size exceeding 3,000m² indicates capacity for batch production

- In-house R&D teams enable customization of travel range, rotary axes, and control software

- Presence of dedicated testing bays ensures pre-shipment performance validation

Cross-reference on-time delivery rates (target ≥90%) and response times (ideally ≤2 hours) as proxies for operational discipline.

Transaction Risk Mitigation

Prioritize suppliers with verifiable transaction histories and post-sale support structures. Use secure payment mechanisms such as escrow services until final inspection clearance. Request sample units to validate build quality, especially for customized configurations involving rotating tables or enclosed safety enclosures. Confirm compliance with regional electrical and safety standards (CE marking preferred) to avoid customs delays.

What Are the Best Multi Axis Machining Equipment Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Dongguan Yahong Automation Equipment Co., Ltd. | Guangdong, CN | 6+ | 30+ | 5,000+m² | 88% | ≤2h | — | 20% |

| Jinan Catek CNC Machinery Co., Ltd | Shandong, CN | 8+ | 50+ | 8,000+m² | 92% | ≤2h | — | 23% |

| Conprofe Technology Group Co., Ltd. | Zhejiang, CN | 10+ | 100+ | 10,000+m² | 100% | ≤11h | — | <15% |

| AVOS AUTO EXPORTS LIMITED | Hunan, CN | 5+ | 20+ | 6,000+m² | — | ≤4h | — | — |

| Oyt Machine Equipment Co., Ltd. | Guangdong, CN | 7+ | 40+ | 4,500+m² | 100% | ≤16h | — | — |

Performance Analysis

Jinan Catek stands out for responsiveness and repeat business (23% reorder rate), indicating strong customer satisfaction in mid-range 5-axis woodworking systems. Conprofe Technology operates at industrial scale with a 100% on-time delivery record and offers high-end metal machining centers priced up to $140,000, reflecting advanced engineering capabilities. Dongguan Yahong provides competitive entry-level five-axis solutions starting at $2,000, though its 88% delivery rate suggests potential bottlenecks during peak demand. Oyt Machine and AVOS AUTO show mixed signals—while both report full on-time fulfillment, their longer response times may impact communication efficiency during commissioning or troubleshooting phases.

FAQs

How to verify multi axis machining equipment supplier reliability?

Validate technical claims through factory audit videos showing live machine testing. Request documentation on spindle brand (e.g., HF, Syil), controller type (SYNTEC, Siemens, or DSP-based), and ball screw specifications (C3 class or higher). Analyze transaction patterns, including minimum order quantities and pricing consistency across product lines.

What is the typical lead time for custom multi-axis machines?

Standard configurations ship within 15–30 days. Custom builds with extended X-axis travel, dual spindles, or specialized software integration require 45–60 days. Add 7–14 days for international shipping via sea freight, depending on destination port congestion.

Can suppliers provide global shipping and installation support?

Yes, most established manufacturers coordinate FOB or CIF shipments with third-party logistics providers. Top-tier suppliers offer remote commissioning via video guidance and basic training materials. On-site technician dispatch may incur additional fees and require advance scheduling.

Do multi axis machining suppliers accept low-volume orders?

MOQs vary: some suppliers require 10-set minimums (common in wood router exports), while others accept single-unit orders at higher per-unit prices. Negotiate flexible terms based on long-term procurement potential or bundled accessory purchases.

How to initiate customization requests for axis configuration?

Submit detailed requirements including work envelope dimensions, desired rotary axis type (A/B or B/C), RPM range (12,000–24,000 for high-speed cutting), and preferred control interface. Leading suppliers respond with CAD layouts and configuration options within 72 hours.