Multilayer Pcb Prototype

CN

CN

1/20

1/20

1/27

1/27

CN

CN

1/2

1/2

CN

CN

1/11

1/11

1/23

1/23

1/38

1/38

1/34

1/34

1/5

1/5

1/60

1/60

1/61

1/61

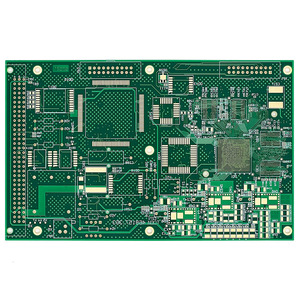

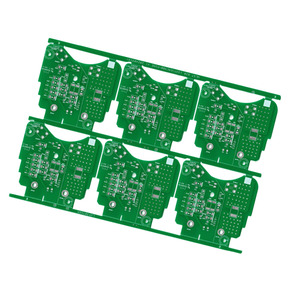

About multilayer pcb prototype

Where to Find Multilayer PCB Prototype Suppliers?

China remains the global hub for multilayer PCB prototype manufacturing, with concentrated supplier clusters in Shenzhen, Dongguan, and Hangzhou driving innovation and cost efficiency. These regions host vertically integrated facilities that combine design support, rapid prototyping, and small-to-medium batch production under one roof. Shenzhen alone accounts for over 50% of China’s high-frequency and HDI PCB output, leveraging proximity to semiconductor R&D centers and automated fabrication lines optimized for fast turnaround.

The ecosystem enables streamlined workflows from gerber file submission to delivery, with many suppliers offering 24–72 hour turnarounds for 4- to 12-layer prototypes. Localized material sourcing—particularly FR-4, Rogers, and aluminum substrates—reduces input costs by 15–25% compared to Western alternatives. Buyers benefit from agile production models supporting MOQs as low as 1 piece, making these clusters ideal for engineering validation, NPI phases, and iterative design testing.

How to Choose Multilayer PCB Prototype Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

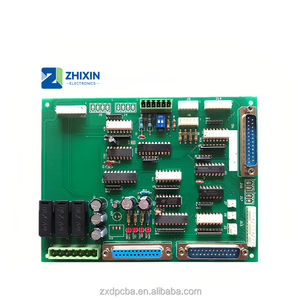

Technical & Quality Compliance

Verify adherence to IPC-6012 Class 2 standards for multilayer board reliability. For high-frequency or HDI applications, confirm capability in impedance control, microvia drilling (≤0.1mm), and buried/blind via technology. RoHS compliance is standard; request material declarations and process flow documentation to validate environmental and safety protocols.

Production Capacity & Flexibility

Assess key indicators of scalability and responsiveness:

- Minimum supported layer count: 4–32 layers (standard range for prototypes)

- Turnkey services including SMT assembly, testing, and conformal coating

- In-house CAM engineering for design-for-manufacturability (DFM) feedback

Cross-reference response time metrics (target ≤2 hours) with on-time delivery rates (ideal ≥98%) to gauge operational efficiency.

Procurement Safeguards

Prioritize suppliers with verifiable performance histories, including reorder rates and dispute resolution records. Use incremental order scaling—start with single-unit prototypes before advancing to batch trials. Request first-article inspection reports (FAIR) and solderability test results prior to volume commitment. Confirm packaging and ESD protection standards for sensitive assemblies.

What Are the Best Multilayer PCB Prototype Suppliers?

| Company Name | Location | Verified Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Toptek Pcb Co., Limited | Shenzhen, CN | Multispecialty Supplier | US $1,000+ | 100% | ≤1h | 66% | 1 piece | $1.01–1.20 |

| Dongguan Xinrongxing Technology Co., Ltd. | Dongguan, CN | Multispecialty Supplier | US $10,000+ | 100% | ≤3h | <15% | 10 pieces | $0.18–1.18 |

| Pinsheng Electronics Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | US $1,000+ | 100% | ≤3h | <15% | 1 piece | $1.00–5.33 |

| Shenzhen Mixinwei Trading Co., Ltd. | Shenzhen, CN | - | US $80,000+ | 100% | ≤2h | 40% | 10 pieces | $0.10–1.00 |

| Hangzhou Jinghuang Electronic Technology Co, Ltd. | Hangzhou, CN | Custom Manufacturer | US $20,000+ | 100% | ≤4h | <15% | 1–5 pieces | $1.00–22.00 |

Performance Analysis

Toptek Pcb Co., Limited stands out for rapid prototyping with a 66% reorder rate and sub-hour response times, indicating strong customer retention and service agility. Shenzhen Mixinwei offers the most competitive pricing at $0.10 per unit (MOQ 10), backed by high online transaction volume, suggesting scalable production capacity. Dongguan Xinrongxing and Hangzhou Jinghuang provide mid-range pricing with customization flexibility, including white silkscreen, blue solder mask, and tailored edge finishes. While several suppliers report 100% on-time delivery, reorder rates below 15% may indicate room for improvement in post-sale support or consistency. Buyers seeking single-board trials should prioritize Toptek or Pinsheng, whereas cost-sensitive batch prototyping favors Mixinwei or Xinrongxing.

FAQs

How to verify multilayer PCB prototype supplier reliability?

Cross-check quality claims with available certifications and request sample test data, including peel strength, thermal cycling results, and AOI reports. Evaluate communication precision during technical inquiries—prompt, detailed responses reflect process maturity. Review transaction history for consistent fulfillment patterns and dispute resolution transparency.

What is the typical lead time for multilayer PCB prototypes?

Standard lead times range from 24 to 72 hours for 4- to 8-layer boards. Complex designs involving HDI, blind vias, or high-frequency materials (e.g., Rogers) may require 5–7 days. Rush services are widely available, often at a 20–30% premium.

Can suppliers handle both PCB fabrication and PCBA?

Yes, multiple suppliers in this dataset offer turnkey solutions, including component sourcing, SMT placement, reflow, testing, and packaging. Confirm availability of BOM management tools and counterfeit part mitigation policies when engaging full PCBA services.

Do multilayer PCB suppliers support small-volume customization?

Most suppliers accommodate custom stack-ups, impedance control, and specialized finishes (ENIG, immersion silver, OSP). Minimum order quantities vary—some accept 1-piece orders, while others require 10+ units for economic processing. Design rule checks (DRC) and DFM feedback are typically provided at no cost.

What payment and shipping terms are common?

Payment options include T/T, PayPal, and secured trade transactions. Shipping methods span express couriers (DHL, FedEx) for samples and air/sea freight for bulk. FOB terms are standard; buyers assume responsibility post-dispatch. Confirm Incoterms and insurance coverage prior to order release.