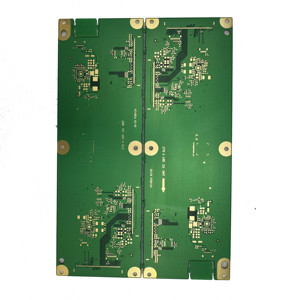

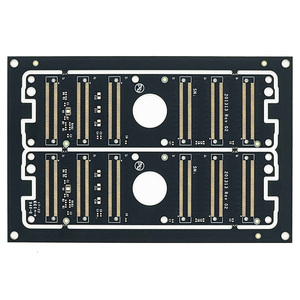

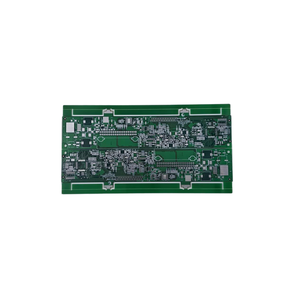

6 Layer Pcb Prototype

CN

CN

1/11

1/11

CN

CN

1/23

1/23

CN

CN

1/20

1/20

CN

CN

1/35

1/35

CN

CN

1/52

1/52

1/24

1/24

1/34

1/34

1/34

1/34

1/20

1/20

About 6 layer pcb prototype

Where to Find 6 Layer PCB Prototype Suppliers?

China remains the global epicenter for printed circuit board (PCB) manufacturing, with Shenzhen and Hangzhou serving as primary hubs for multilayer PCB production. These regions host vertically integrated supply chains that streamline prototyping workflows—from substrate material sourcing to final assembly—enabling rapid turnaround times. Shenzhen alone accounts for over 60% of China’s high-density interconnect (HDI) and multilayer PCB output, supported by a dense network of FR4 material suppliers, photolithography services, and surface finish providers within a 30km radius.

The industrial ecosystem supports agile prototyping with batch scalability, where suppliers leverage automated optical inspection (AOI), impedance-controlled routing, and immersion gold/silver surface finishes to meet IPC-6012 Class 2 standards. Lead times for 6-layer PCB prototypes typically range from 5–10 days, with express options available in 3–5 days. Localized logistics reduce component procurement delays, while standardized processes enable cost efficiencies—prototypes are commonly offered at $0.30–$10 per piece depending on complexity and order volume.

How to Choose 6 Layer PCB Prototype Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

Confirm support for minimum trace widths/spacing (typically 4/4 mil), via-in-pad technology, and controlled impedance design. Suppliers should offer standard materials such as FR4 TG170 and UL-certified laminates, with surface finishes including ENIG, OSP, and immersion silver. Verify Gerber file compatibility and design-for-manufacturability (DFM) feedback availability.

Production Infrastructure

Assess key indicators of manufacturing maturity:

- In-house lamination and drilling lines for 4–12 layer boards

- On-site AOI and flying probe testing capabilities

- Monthly prototype capacity exceeding 5,000 units

Cross-reference response time data (<5 hours preferred) and on-time delivery performance (target ≥98%) to gauge operational reliability.

Quality & Compliance Verification

Prioritize suppliers adhering to ISO 9001 quality management systems. For electronics destined for regulated markets, ensure RoHS and REACH compliance documentation is available. Request first-article inspection reports and process audit trails for critical layers to validate consistency in stack-up alignment and plating uniformity.

What Are the Best 6 Layer PCB Prototype Suppliers?

| Company Name | Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (per unit) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Jinghuang Electronic Technology Co, Ltd. | Custom Manufacturer | US $20,000+ | 100% | ≤5h | <15% | 5 pieces | $5–$188 | Color, material, size, logo, packaging, label, graphic |

| Guangdong Global Well Electronic Limited | OEM/ODM | US $60,000+ | 100% | ≤5h | 33% | 1 piece | $0.30–$10 | Not specified |

| Shenzhen Cengfeng Electronics Co., Ltd. | Manufacturer | - | 100% | ≤4h | - | 1 piece | $2.69–$21.89 | UL certification, multilayer variants |

| Shenzhen Xinjiaye Electronics Technology Co., Ltd. | Manufacturer | US $2,000+ | 100% | ≤14h | 33% | 1 piece | $1.20–$50 | Limited customization |

| Shenzhen Leadsintec Technology Co., Ltd. | OEM/ODM | - | 100% | ≤3h | - | 10 pieces | $0.90–$6.09 | Full turnkey PCBA services |

Performance Analysis

Guangdong Global Well and Shenzhen Cengfeng stand out for low-volume flexibility, supporting single-piece orders with competitive pricing and fast response times. Hangzhou Jinghuang offers extensive customization but enforces higher minimums (5+ units), indicating a focus on pre-series production. Shenzhen Leadsintec provides tight cost control for mid-batch prototyping (10–50 units), ideal for iterative development cycles. Suppliers with sub-5-hour average response times demonstrate higher service engagement, correlating with stronger post-order support. Reorder rates above 30%, as seen in Global Well and Xinjiaye, suggest customer satisfaction in quality consistency and communication efficiency.

FAQs

How to verify 6 layer PCB prototype supplier reliability?

Validate technical competence through sample testing, focusing on dielectric thickness consistency, via aspect ratios (ideally ≤8:1), and solder mask adhesion. Request evidence of internal quality audits and cross-check online transaction histories for dispute patterns or delayed shipments.

What is the typical lead time for 6-layer PCB prototypes?

Standard lead times range from 7–10 working days. Accelerated services can deliver in 3–5 days using expedited lamination and etching schedules. Add 2–4 days for PCBA integration if components are not supplied.

Do suppliers support small MOQs for prototyping?

Yes, most suppliers accommodate MOQs of 1–5 pieces. Guangdong Global Well and Shenzhen Cengfeng allow single-board orders, making them suitable for initial design validation before scaling.

Are customization options available for stack-up and materials?

Advanced suppliers permit adjustments to core thickness, prepreg count, and copper weight (e.g., 1oz to 2oz). UL-certified materials and impedance-controlled designs are commonly supported upon request.

Can I get free samples or prototype trials?

Free samples are rare for custom PCBs due to fabrication costs. However, some suppliers waive setup fees for repeat customers or absorb costs when followed by volume production orders. Prototype pricing often includes engineering charges amortized over the batch.