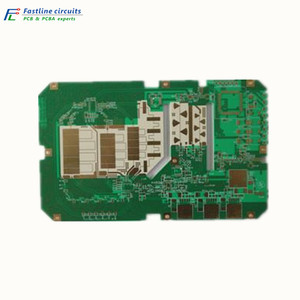

4 Layer Pcb Prototype

Top sponsor listing

Top sponsor listing

About 4 layer pcb prototype

Where to Find 4 Layer PCB Prototype Suppliers?

China remains the global epicenter for printed circuit board (PCB) manufacturing, with Shenzhen and Dongguan emerging as key hubs for multilayer PCB production. These regions host vertically integrated facilities specializing in rapid prototyping and low-to-mid volume assembly, supported by mature supply chains for FR-4 laminates, copper foils, and surface finish materials. The concentration of technical expertise and component distributors within a 50km radius enables streamlined production cycles, particularly for 4-layer PCB prototypes requiring tight impedance control and controlled dielectric spacing.

Suppliers in this ecosystem leverage automated optical inspection (AOI), X-ray testing, and impedance-controlled stack-up design to meet IPC-6012 Class 2 standards as baseline quality assurance. Buyers benefit from scalable capacity, with leading manufacturers operating multiple production lines capable of processing 10,000+ panel units monthly. Localized sourcing of materials reduces lead times to 5–7 days for standard 4-layer prototypes and enables cost efficiency, with average pricing ranging from $0.15 to $2.50 per unit depending on complexity and order volume.

How to Choose 4 Layer PCB Prototype Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Technical Capability Verification

Confirm the supplier’s ability to handle 4-layer stack-up designs with precise via drilling (mechanical or micro-via), buried/blind via options, and impedance control within ±10%. Evaluate material compatibility—FR-4 high Tg, halogen-free, or Rogers substrates—and surface finishes such as ENIG, HASL, or immersion silver. Request fabrication notes and Gerber file review protocols to ensure design-for-manufacturability alignment.

Production & Quality Infrastructure

Assess operational scale through verifiable metrics:

- Minimum 3,000m² factory area with dedicated clean rooms for lamination and etching

- In-house capabilities covering inner layer imaging, press-fit vias, solder mask application, and electrical testing (flying probe or fixture-based)

- Adherence to ISO 9001, IATF 16949, or UL certification where applicable

Cross-reference on-time delivery performance (target ≥98%) and response time (<4 hours) with documented reorder rates to gauge reliability and service consistency.

Procurement Risk Mitigation

Utilize secure transaction mechanisms that align payment milestones with production stages. Prioritize suppliers offering free DFM feedback and prototype validation reports. Conduct sample testing for critical parameters: peel strength, thermal cycling resistance (up to 288°C), and continuity/shorts testing. For integrated PCBA services, verify BOM sourcing accuracy, component authenticity, and traceability protocols.

What Are the Best 4 Layer PCB Prototype Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Dongguan Tuopst Technology Co., Ltd. | Dongguan, CN | Multilayer PCB, Aluminum PCB, FPC | US $3,000+ | 100% | ≤2h | 100% | Limited | 10 pcs |

| Dongguan Xinrongxing Technology Co., Ltd. | Dongguan, CN | Multilayer PCB, FPC | US $10,000+ | 100% | ≤2h | 25% | Yes (color, finish, assembly) | 10 pcs |

| Shenzhen Co-Etech Limited | Shenzhen, CN | Other ICs, Electronic Components | US $30,000+ | 100% | ≤2h | <15% | Limited | 1 pc |

| Shenzhen Wonstron Technology Co., Ltd. | Shenzhen, CN | PCBA, Multilayer PCB | US $260,000+ | 100% | ≤2h | 20% | Extensive (BOM, assembly, reverse engineering) | 1 pc |

| Shenzhen Cengfeng Electronics Co., Ltd. | Shenzhen, CN | PCBA, HDI PCB, High Frequency PCB | Not disclosed | 100% | ≤4h | No data | Yes (UL-certified, multilayer up to 32 layers) | 1 pc |

Performance Analysis

Dongguan-based suppliers emphasize fast turnaround and consistent delivery, with both Tuopst and Xinrongxing maintaining ≤2-hour response times and perfect on-time records. Tuopst stands out with a 100% reorder rate, indicating strong buyer retention despite limited customization scope. In contrast, Shenzhen-based firms offer broader technical flexibility: Wonstron supports full BOM integration and reverse engineering, while Cengfeng provides UL-certified multilayer boards up to 32 layers, catering to advanced applications. Co-Etech offers the lowest MOQ (1 piece), ideal for initial R&D testing. However, its lower reorder rate suggests potential gaps in post-sale support or scalability. Buyers prioritizing end-to-end prototyping should favor suppliers with documented PCBA integration and material traceability systems.

FAQs

How to verify 4 layer PCB prototype supplier reliability?

Validate compliance with IPC-6012 and ISO 9001 standards through audit documentation. Request sample batches with test coupons verifying plating thickness, isolation resistance, and thermal stress performance. Analyze supplier communication patterns, DFM feedback quality, and responsiveness during pre-order inquiries.

What is the typical lead time for 4 layer PCB prototypes?

Standard lead time ranges from 5 to 7 working days for bare boards. Quick-turn options (3–4 days) are available at a premium. Additional time (5–10 days) applies for PCBA, depending on component availability and testing requirements.

Do suppliers support small-batch customization?

Yes, most suppliers accommodate orders as low as 1–10 pieces with full customization including board thickness (0.4–3.2mm), copper weight (½ oz to 3 oz), and surface finishes. Advanced features like blind vias or impedance matching may require minimum batch sizes of 20+ units.

Are there additional costs for DFM analysis or file review?

No, reputable suppliers provide free Design for Manufacturing (DFM) checks to identify layout risks such as insufficient annular rings, trace clearance violations, or solder mask slivers before production begins.

Can suppliers handle complete turnkey PCBA projects?

Yes, select suppliers like Wonstron and Cengfeng offer turnkey solutions including component procurement, BOM optimization, automated assembly, functional testing, and packaging. Full traceability and RoHS compliance documentation are typically provided upon request.