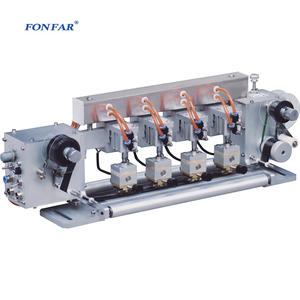

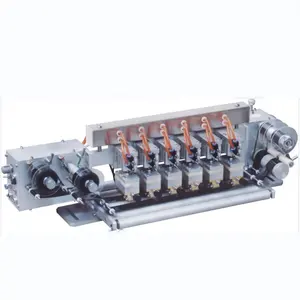

Multipurpose Batch Coding And Printing Machine

1/13

1/13

1/16

1/16

1/16

1/16

1/10

1/10

1/11

1/11

About multipurpose batch coding and printing machine

Where to Find Multipurpose Batch Coding and Printing Machine Suppliers?

China remains the global hub for manufacturing multipurpose batch coding and printing machines, with key production clusters concentrated in Hubei, Hunan, and Guangdong provinces. Wuhan (Hubei) and Changsha (Hunan) host advanced packaging machinery ecosystems supported by robust R&D infrastructure and integrated supply chains for inkjet systems, control electronics, and mechanical components. These regions benefit from proximity to tier-one logistics hubs, enabling efficient export fulfillment to Europe, North America, and Southeast Asia.

The industrial clusters support vertically aligned production, combining precision machining, electronic assembly, and software integration under one ecosystem. This enables rapid prototyping and scalable output, with lead times averaging 15–30 days for standard units. Localized sourcing of critical subsystems—such as TIJ (Thermal Inkjet) printheads and CIJ (Continuous Inkjet) modules—reduces production costs by 20–35% compared to Western alternatives. Buyers gain access to flexible manufacturing setups capable of fulfilling both low-volume trials and bulk orders exceeding 500 units monthly.

How to Choose Multipurpose Batch Coding and Printing Machine Suppliers?

Selecting reliable suppliers requires adherence to structured evaluation criteria focused on technical capability, operational performance, and transaction security.

Technical Compliance & Equipment Types

Verify supplier expertise across core printing technologies: Thermal Inkjet (TIJ), Continuous Inkjet (CIJ), and handheld/static models. Machines should support multi-language character sets, variable data printing (batch numbers, expiry dates, barcodes), and compatibility with substrates including plastic, glass, metal, and cardboard. CE certification is essential for EU market compliance; ISO 9001 registration indicates formal quality management systems. Request documentation for printhead durability, ink resistance (to water, oil, abrasion), and environmental operating ranges (typically 0–45°C).

Production Capability Verification

Assess operational scale and engineering capacity through the following indicators:

- Minimum factory area of 2,000m² for dedicated assembly lines

- In-house design teams for firmware customization and interface development (e.g., touchscreen HMI)

- Integration capabilities for inline automation (conveyor synchronization, sensor triggering)

- On-time delivery rate ≥96% and response time ≤3 hours for timely communication

Cross-reference claimed capabilities with verifiable online revenue metrics and product range diversity. Suppliers offering laser marking or sealing machines alongside coding systems often possess broader systems integration experience.

Transaction Safeguards & Procurement Best Practices

Utilize secure payment mechanisms such as escrow services to mitigate risk. Prioritize suppliers participating in verified trade programs with documented dispute resolution histories. Conduct sample testing to evaluate print clarity (minimum 200 dpi), drying time, adhesion strength, and long-term reliability under continuous operation. For customized configurations, request firmware demo videos or remote UI walkthroughs before finalizing orders.

What Are the Best Multipurpose Batch Coding and Printing Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | Inkjet Printers, Sealing Machines, Laser Marking Machines | US $40,000+ | 96% | ≤3h | <15% | Not specified | 1 set |

| Hunan Binxin Digital Technology Co., Ltd. | Hunan, CN | Inkjet Printers, Ink Cartridges, Printing Machinery Parts | US $90,000+ | 100% | ≤1h | <15% | Not specified | 1 piece/unit |

| Foshan Denoma Electronic Technology Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $50,000+ | 100% | ≤1h | 16% | Color, material, size, logo, packaging, graphic | 1 piece |

| Hefei Minssine Packaging Technology Co., Ltd. | Anhui, CN | Multispecialty Supplier | US $30,000+ | 100% | ≤3h | <15% | Not specified | 1 set/piece |

| Wuhan Bangle Mark Technology Co., Ltd. | Hubei, CN | Inkjet Printers, Conveyors, Laser Engraving Machines | US $60,000+ | 100% | ≤2h | <15% | Not specified | 1 set |

Performance Analysis

Hunan Binxin Digital Technology leads in responsiveness (≤1h) and transaction volume (US $90,000+), indicating strong customer acquisition and service efficiency. Foshan Denoma stands out for customization breadth, supporting modifications in color, branding, and packaging—critical for OEM partnerships. Multiple suppliers report 100% on-time delivery rates, reflecting mature logistics coordination. Wuhan-based manufacturers dominate regional clustering, with two suppliers based in the city leveraging shared technical labor pools and component suppliers. While reorder rates are generally low (<15%), this may reflect project-based procurement patterns rather than dissatisfaction. Suppliers with multispecialty portfolios demonstrate adaptability in system integration, beneficial for turnkey line installations.

FAQs

How to verify multipurpose batch coding machine supplier reliability?

Confirm ISO 9001 certification status through accredited registrars. Request evidence of product compliance (CE, RoHS) and conduct video audits of production floors. Analyze transaction history, focusing on consistent on-time delivery and responsive communication. Review customer feedback on after-sales support, particularly firmware updates and spare parts availability.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Customized units with specific language support or interface changes may require 18–25 days. Air shipping adds 5–10 business days for international delivery. Sample costs typically range from $30 to $470, depending on technology (handheld vs. automated TIJ/CIJ systems).

Can suppliers ship globally?

Yes, all listed suppliers have export experience. Confirm Incoterm preferences (FOB, CIF) and ensure packaging meets international standards for shock and moisture resistance. Most offer air freight for samples and sea containers for bulk orders, with DDP options available upon request.

Do suppliers provide free samples?

Free samples are uncommon due to equipment complexity and cost. However, some suppliers credit sample fees toward subsequent bulk orders, typically those exceeding 5–10 units. Negotiate sample reimbursement terms prior to payment.

How to initiate customization requests?

Submit detailed specifications including print height (e.g., 12.7mm, 25.4mm), substrate type, production line speed (for inline models), required languages, and desired connectivity (USB, Ethernet, relay triggers). Reputable suppliers respond with technical proposals and UI mockups within 48–72 hours, followed by prototype builds in 3–4 weeks.