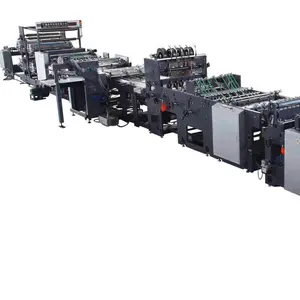

Notebook Paper Making Machine

CN

CN

CN

CN

CN

CN

About notebook paper making machine

Where to Find Notebook Paper Making Machine Suppliers?

China remains the global epicenter for notebook paper making machine manufacturing, with key production hubs in Shandong, Guangdong, and Henan provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, cost-efficient labor, and proximity to raw material sources such as recycled pulp and bagasse. Qingdao (Shandong) and Dongguan (Guangdong) specialize in automated post-press and paper processing systems, while Henan’s machinery clusters focus on high-capacity paper forming and converting lines.

The concentration of suppliers in these zones enables streamlined component sourcing, reducing lead times and assembly costs. Integrated supply chains allow for rapid prototyping and scalable production, with standard delivery windows ranging from 30 to 60 days depending on automation level. Buyers benefit from localized expertise in kraft paper handling, conical nail binding, and A4/A3 sheet calibration, along with access to modular machines capable of producing 1–5 tons per day. Customization options include adjustable paper core diameter, waste wood capacity, and graphic labeling systems, supporting diverse market needs from school exercise books to office notebooks.

How to Choose Notebook Paper Making Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Verify whether the supplier offers end-to-end solutions—from pulp preparation to final binding—or specializes in discrete stages like notching, creasing, or laminating. Prioritize manufacturers with documented experience in semi-automatic or fully automatic lines, particularly those integrating printing, cutting, and pressing functions. Look for evidence of R&D investment through product variants (e.g., wire-stitching vs. adhesive binding machines) and customization depth (material size, logo embossing, packaging design).

Quality Assurance and Compliance

While ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates above 95% and low reorder rates suggest stable quality control processes. For international buyers, confirm CE marking or equivalent safety compliance to ensure regulatory acceptance. Request test reports for critical performance metrics such as laminating speed, hydraulic pressure tolerance, and die-cutting precision. Machines designed for continuous operation should demonstrate thermal stability and wear-resistant components.

Supplier Reliability Indicators

Analyze response time and fulfillment consistency:

- Target suppliers with response times ≤2 hours for timely communication

- Prioritize on-time delivery rates ≥98% to minimize supply chain disruption

- Evaluate online revenue indicators (e.g., US $370,000+) as proxies for export volume and customer base maturity

- Assess customization breadth—such as label, color, foil stamping, or pull-cut functionality—as evidence of flexible manufacturing infrastructure

Procurement Safeguards

Utilize secure payment mechanisms tied to milestone inspections. Conduct virtual factory audits to verify claimed production capacity and equipment condition. Request physical or digital samples to assess build quality before full-scale orders. Confirm minimum order quantities (typically 1 set/unit) and clarify FOB terms, especially for heavy machinery requiring specialized freight handling.

What Are the Best Notebook Paper Making Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Customization Options | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Qingdao YiDaFa International Trade Co., Ltd. | Shandong, CN | Paper making machine, notebook | $140,000–220,000 | 1 set | 100% | ≤2h | kraft paper, thickness, binding, logo, graphic, tons/day | <15% |

| Dongguan Linhang Intelligent Equipment Co., Ltd. | Guangdong, CN | Notebook making machine, post-press equipment | $1,100–14,000 | 1 set | 100% | ≤2h | binding type, size, graphic | Not specified |

| Suzhou Ruicai Electron Co., Ltd. | Jiangsu, CN | Paper processing, heat press, notching machines | $530–$9,000 | 1 unit/piece | 96% | ≤9h | multi-function packaging, laminating, pressing | <15% |

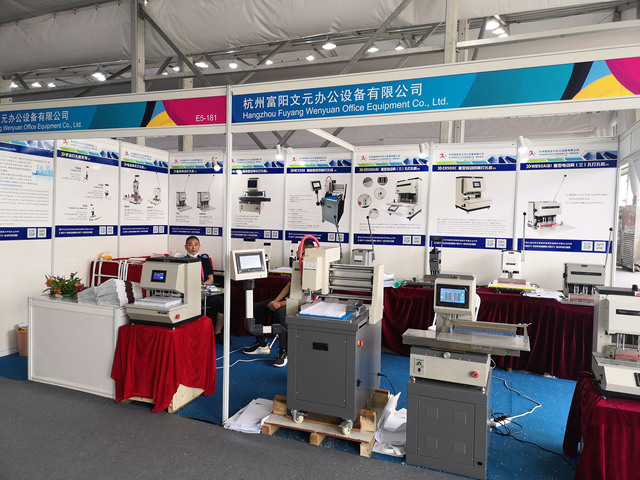

| Hangzhou Caide Office Equipment Co., Ltd. | Zhejiang, CN | Booklet maker, paper cutter, binding machine | $305–$21,500 | 1 piece/set | 98% | ≤3h | die cutter, roll size, laminating speed, logo | <15% |

| Henan Yugong Machinery Equipment Co., Ltd. | Henan, CN | A4/A3 paper making machine, high-speed systems | $12,800–18,800 | 1 set | 85% | ≤4h | material, size, packaging, graphic | 19% |

Performance Analysis

Qingdao YiDaFa stands out for high-end automation with prices exceeding $200,000, targeting large-scale producers needing full-line integration and daily output optimization. In contrast, Dongguan Linhang offers entry-level and mid-range solutions ideal for small to medium enterprises seeking affordable wire-bound or softcover notebook production. Suzhou Ruicai and Hangzhou Caide provide niche equipment focused on finishing operations—such as nipping, notching, and laminating—making them suitable for hybrid setups where upstream paper formation occurs offsite.

Henan Yugong presents competitively priced standard models but exhibits lower on-time delivery performance (85%) and a higher reorder rate (19%), indicating potential service inconsistencies. Suppliers based in Shandong and Guangdong demonstrate superior responsiveness (≤2h), aligning with regional strengths in export-oriented customer service. Buyers prioritizing scalability should favor suppliers with extensive customization portfolios and verified delivery records above 98%.

FAQs

How to verify notebook paper making machine supplier reliability?

Cross-check declared response times and on-time delivery rates against transaction histories. Request facility videos or live calls to validate production lines. Review customization capabilities as an indicator of technical flexibility and in-house engineering strength.

What is the typical lead time for notebook paper making machines?

Standard configurations typically ship within 30–45 days after order confirmation. Customized systems may require 60+ days depending on complexity. Air freight is rarely used due to weight; sea freight under FOB or CIF terms is standard.

Can suppliers accommodate custom specifications?

Yes, most suppliers support modifications including paper size (A4, A3, A5), binding method (wire, glue, staple), and branding elements (logo, graphic, packaging). High-end models allow adjustments to pulp input type (recycled, bagasse) and output capacity (tons per day).

Do manufacturers offer free samples or trial runs?

Free samples are uncommon due to machine scale. However, some suppliers provide digital simulations or video demonstrations of machine operation. For physical validation, expect to pay partial costs for prototype testing or on-site trials.

What are common payment terms for industrial paper machinery?

Typical arrangements include 30% advance payment via T/T, with balance due before shipment. Escrow services or trade assurance programs are recommended for first-time transactions to mitigate risk.