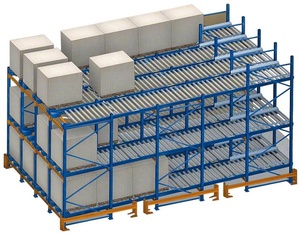

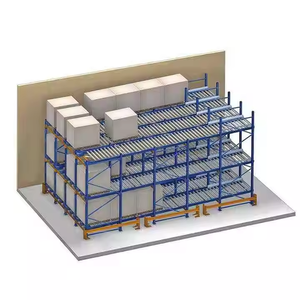

Pallet Flow Racking System

Top sponsor listing

Top sponsor listing

TR

TR

CN

CN

CN

CN

CN

CN

About pallet flow racking system

Where to Find Pallet Flow Racking System Suppliers?

China remains the central hub for pallet flow racking system manufacturing, with key production clusters concentrated in Jiangsu, Hubei, and Guangxi provinces. Nanjing in Jiangsu Province hosts a high concentration of specialized logistics equipment manufacturers, supported by mature steel processing infrastructure and proximity to major export ports like Shanghai. This regional advantage enables efficient inbound material sourcing and outbound container shipping, reducing logistics overhead by 10–15% compared to inland regions.

These industrial ecosystems feature vertically integrated supply chains—from cold-rolled steel coil processing to automated powder coating lines—allowing suppliers to maintain tight control over cost and quality. Facilities typically operate under lean manufacturing principles, supporting batch production scalability and rapid reconfiguration for custom designs. Buyers benefit from short lead times (average 20–35 days for standard systems) and flexible order structuring, including modular component supply or full warehouse layout integration. The presence of technical engineering teams within most factories further enhances design-to-delivery efficiency, particularly for high-density FIFO (First-In, First-Out) storage solutions.

How to Choose Pallet Flow Racking System Suppliers?

Selecting reliable partners requires systematic evaluation across three critical dimensions:

Engineering & Customization Capability

Verify that suppliers offer structural design services aligned with load dynamics and warehouse layout constraints. Key indicators include availability of CAD/BIM modeling, capacity simulation tools, and customization options for beam length, roller pitch, incline angle, and load-bearing specifications (typically ranging from 500kg to 5,000kg per level). Confirm material traceability—Q235 or Q345 structural steel is standard—with factory-applied anti-corrosion treatments such as galvanizing or epoxy powder coating.

Production Capacity & Operational Metrics

Assess infrastructure maturity through verifiable benchmarks:

- Minimum monthly output capacity exceeding 500 sets or 100,000 kg

- In-house fabrication capabilities including roll forming, robotic welding, punching, and surface finishing

- Dedicated quality inspection protocols pre- and post-assembly

Cross-reference on-time delivery performance (target ≥98%) and response time (ideally ≤2 hours) as proxies for operational discipline.

Transaction Reliability & Quality Assurance

Prioritize suppliers with documented quality management systems, ideally ISO 9001 certified. Request test reports for static load testing and deflection measurements. For international buyers, ensure compatibility with global safety standards such as FEM 10.2.02 (Europe) or RMI/AISC (North America). Utilize secure payment mechanisms tied to milestone verification, especially for large-scale installations. Pre-shipment inspections should include dimensional accuracy checks, weld integrity assessment, and labeling consistency.

What Are the Best Pallet Flow Racking System Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Basis |

|---|---|---|---|---|---|---|---|---|

| Nanjing Jinhui Storage Equipment Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | US $2,300,000+ | 100% | ≤2h | 16% | Color, load capacity, beam length, material, size, graphic, logo | Multiple SKUs (kg/set) |

| Nanjing A-Plus Metal Products Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | US $730,000+ | 75% | ≤1h | 33% | Rack color, loading gate, mezzanine, cold storage adaptation, dimensions | 1,000–10,000 kg |

| Wuhan Yongguan Storage Equipment Co., Ltd. | Hubei, CN | Not Verified | US $1,000+ | 100% | ≤3h | <15% | Limited public data | Set-based (1–10 sets) |

| Guangxi Nanning Jianzhian Integrated Housing Co., Ltd. | Guangxi, CN | Multispecialty Supplier | US $960,000+ | 98% | ≤2h | 29% | Color, capacity, layers, height, legs, design, lead time | Unit-based (1–2 units) |

| Nanjing Peter Logistics Equipment Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $60,000+ | 100% | ≤3h | 20% | Full system specs: frame, station, label, graphic, material, layers | As low as 20 kg |

Performance Analysis

Nanjing-based suppliers dominate both volume and customization depth, with Jinhui and Peter Logistics demonstrating full engineering control over system design and material specification. Despite lower revenue visibility, Wuhan Yongguan maintains perfect on-time delivery, suggesting strong production planning despite limited reorder activity. A-Plus Metal stands out for customer retention (33% reorder rate), indicating satisfaction with product fit and service continuity. Notably, Nanjing Peter Logistics offers the lowest minimum order threshold (20 kg), making it suitable for prototyping or partial system upgrades. Suppliers offering set-based pricing (e.g., 10-set MOQs) typically target complete bay installations, whereas per-kg pricing supports incremental expansion projects.

FAQs

How to verify pallet flow racking system supplier reliability?

Cross-check declared certifications (e.g., ISO 9001) with accredited bodies. Request structural calculation sheets and material mill certificates. Evaluate responsiveness consistency and technical clarity in communication. Third-party audit reports or factory walkthrough videos add validation for remote procurement.

What is the typical lead time for custom systems?

Standard orders require 20–30 days post-design approval. Fully customized configurations involving non-standard rollers, extended beams, or seismic reinforcement may extend to 45 days. Sample components (e.g., single lanes or support frames) can be produced in 10–15 days.

Can suppliers provide turnkey installation support?

Some suppliers offer site surveys and assembly guidance, though on-site installation is typically subcontracted locally. Technical documentation, torque specifications, and alignment procedures are generally provided in English. For large deployments, request detailed erection manuals and training materials.

Do manufacturers support small trial orders?

Yes, several suppliers accept trial runs as low as 20 kg or one unit. These are ideal for validating roller smoothness, structural rigidity, and compatibility with existing handling equipment. Sample costs often offset against future bulk orders.

How to initiate a customization request?

Submit warehouse layout drawings, pallet dimensions (standard EUR/ISO or custom), desired lane depth (3–15 pallets deep), required slope gradient (2–5°), and dynamic load requirements. Reputable suppliers will return layout proposals with load distribution analysis and component breakdown within 3–5 business days.