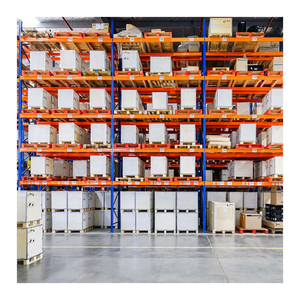

Warehouse Pallet Racking System

Top sponsor listing

Top sponsor listing

1/2

1/2

1/24

1/24

1/3

1/3

1/1

1/1

CN

CN

1/13

1/13

1/20

1/20

1/16

1/16

1/27

1/27

1/3

1/3

1/17

1/17

1/3

1/3

1/26

1/26

1/40

1/40

0

0

0

0

1/1

1/1

1/23

1/23

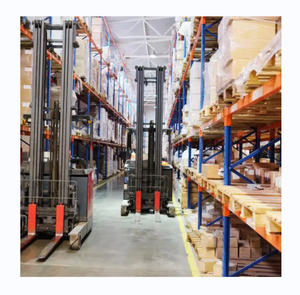

About warehouse pallet racking system

Where to Find Warehouse Pallet Racking System Suppliers?

China remains the central hub for industrial storage infrastructure, with key supplier clusters concentrated in Guangdong, Henan, and Foshan regions. These areas host vertically integrated manufacturers specializing in steel-based material handling systems, leveraging localized access to cold-rolled steel, automated fabrication lines, and powder coating facilities. The proximity to major ports such as Guangzhou and Qingdao enables efficient export logistics, reducing transit time by 10–15 days compared to inland production zones.

Suppliers in these industrial zones operate within mature ecosystems that include structural engineering teams, galvanization services, and modular assembly units—all within a 50-kilometer radius. This integration supports rapid prototyping and scalable production, with standard lead times averaging 20–35 days for container-sized orders. Buyers benefit from 20–30% lower unit costs due to reduced material transportation and labor efficiency, particularly for high-capacity selective, drive-in, or mezzanine racking configurations.

How to Choose Warehouse Pallet Racking System Suppliers?

Procurement decisions should be guided by objective verification criteria to ensure structural integrity, compliance, and supply chain reliability:

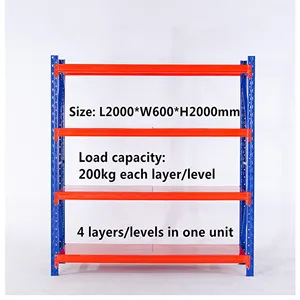

Structural & Material Specifications

Confirm use of Q235 or Q345-grade steel with thickness ranging from 1.5mm to 3.0mm for uprights and beams. Verify load capacity documentation per bay (typically 2,000–5,000 kg) and request detailed CAD drawings for beam deflection, upright bracing, and floor anchoring. For humid or corrosive environments, insist on hot-dip galvanized or epoxy-coated components.

Quality Assurance Protocols

Prioritize suppliers with ISO 9001 certification and documented quality control processes. Request test reports for salt spray resistance (for coated racks), weld integrity, and bolt torque specifications. On-time delivery rates above 95% and reorder rates exceeding 20% indicate operational consistency and customer satisfaction.

Customization & Technical Support

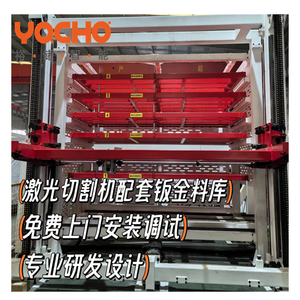

Evaluate suppliers’ ability to provide:

- Custom configurations (tier count, layer spacing, deck type, staircase integration)

- Load-bearing calculations and layout design services

- Powder coating color matching (RAL standards) and labeling options

- Assembly drawings, installation manuals, and guardrail integration

Cross-reference customization claims with actual product listings and technical tags to confirm implementation depth.

Transaction Security & Sampling

Utilize secure payment methods with milestone-based disbursement. Require physical or digital samples—especially for critical joints or connectors—before full-scale ordering. Standard sampling lead time ranges from 7–14 days, with shipping via express courier taking an additional 5–8 days internationally.

What Are the Best Warehouse Pallet Racking System Suppliers?

| Company Name | Supplier Type | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Main Product Lines | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Maobang Storage Equipment Co., Ltd. | Custom Manufacturer | 92% | ≤3h | 23% | US $1,400,000+ | Yes | Stacking Racks & Shelves, Mezzanine Systems, Supermarket Shelves | Multiple configurations per order |

| Luoyang Morgie Electronic Commerce Co., Ltd. | Manufacturer | 96% | ≤5h | <15% | US $530,000+ | Yes | Heavy-Duty Metal Racks, Mobile Automation Racks, Industrial Shelving | 30-set minimum |

| Foshan Jiuhua Industrial Equipment Co., Ltd. | Manufacturer | 96% | ≤1h | 23% | US $80,000+ | Limited | Industrial Pallet Racks, Conveyors, Storage Cages | As low as 1 piece |

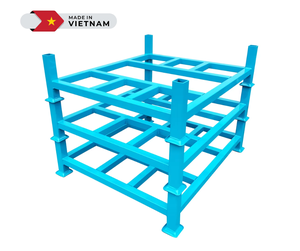

| QUANG MIN COMPANY LIMITED | Manufacturer | 100% | ≤1h | - | US $40,000+ | No | Steel Pallet Racks, Drive-In Racking, Diamond-Style Storage | 999kg minimum (bulk weight-based) |

| GUANGMING VIET NAM COMPANY LIMITED | Manufacturer | - | ≤3h | - | - | Limited | Heavy-Duty Teardrop Racks, Industrial Shelving | 10–1000kg minimums |

Performance Analysis

Guangzhou Maobang leads in revenue volume and customization breadth, offering comprehensive solutions including mezzanine floors and elevator-integrated systems—ideal for complex warehouse retrofits. Luoyang Morgie demonstrates strong technical agility with support for automation-ready mobile racks and detailed specification control (e.g., epoxy finish, tier spacing). Foshan Jiuhua stands out for low MOQ flexibility, enabling buyers to test designs with single-piece orders, while QUANG MIN achieves perfect on-time delivery despite limited customization, suggesting optimized production scheduling.

Buyers seeking tailored warehouse layouts should prioritize suppliers with proven design capabilities and response times under 5 hours. For commodity-style pallet racks, cost-per-kilogram models (e.g., $0.80–1.20/kg) from bulk-focused suppliers offer economic advantages. Always validate load capacity claims against third-party structural benchmarks or regional standards such as FEM 10.2.02 or AS 4084.

FAQs

How to verify warehouse pallet racking system supplier reliability?

Request factory audit reports, ISO certifications, and customer references from similar industries. Analyze response patterns: consistent sub-3-hour replies correlate with stronger project management. Check for inclusion of technical documentation such as assembly diagrams, load tables, and material test certificates.

What is the typical MOQ for pallet racking systems?

MOQ varies by supplier and component type. Beam-and-upright sets often require 30–50 units, while panelized systems may be priced per kilogram (e.g., 999kg minimum). Some manufacturers allow mixed SKUs within a container to accommodate diverse rack configurations.

Can suppliers provide engineered drawings for approval?

Yes, leading suppliers offer pre-production CAD layouts, 3D renderings, and load distribution plans. These should include upright dimensions, beam length, deck type, and safety guardrail placement. Approval cycles typically take 3–5 business days after inquiry submission.

Do manufacturers support international logistics?

Most established suppliers manage FOB and CIF shipments globally. Confirm packaging standards (e.g., flat-pack vs. pre-assembled), container loading efficiency, and compatibility with local forklift clearances. Sea freight is standard; air shipping is viable only for urgent spare parts.

How long does customization take?

Custom design integration adds 5–10 days to production timelines. Full turnkey projects involving multi-tier mezzanines or automation interfaces may require 45–60 days from concept to shipment, depending on engineering complexity and client feedback speed.