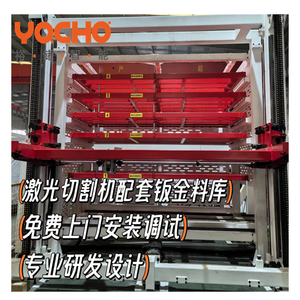

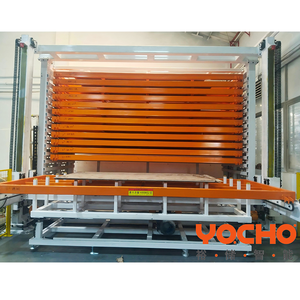

Automated Pallet Racking System

1/3

1/3

1/17

1/17

1/3

1/3

1/1

1/1

0

0

CN

CN

0

0

1/3

1/3

CN

CN

0

0

1/40

1/40

0

0

1/38

1/38

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/3

1/3

About automated pallet racking system

Where to Find Automated Pallet Racking System Suppliers?

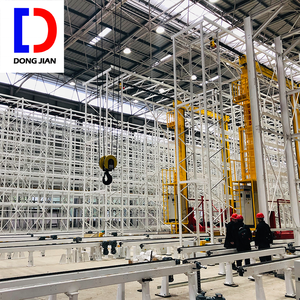

China remains the central hub for automated pallet racking system manufacturing, with key production clusters in Fujian, Guangxi, and Chongqing offering specialized capabilities. Xiamen and Chongqing host advanced facilities integrating automation engineering with structural steel fabrication, enabling end-to-end development of ASRS (Automated Storage and Retrieval Systems) and shuttle-based racking solutions. These regions benefit from proximity to Tier-1 logistics infrastructure and established supply chains for galvanized steel, wire mesh decking, and radio shuttle components.

The industrial ecosystems support vertically integrated operations—from material processing to final assembly—allowing suppliers to maintain tight control over lead times and customization. Buyers gain access to manufacturers equipped with CNC roll-forming lines, robotic welding stations, and modular design software, facilitating rapid prototyping and scalable production. Typical advantages include 20–35% cost savings compared to Western suppliers, standard lead times of 25–40 days for customized systems, and flexibility in load capacity (ranging from 500kg to over 3,000kg per level).

How to Choose Automated Pallet Racking System Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Structural Compliance

Confirm adherence to international material and safety standards, including ISO 9001 for quality management and EN 15512 for steel static storage systems. For high-density automated installations, verify compatibility with warehouse control systems (WCS) and integration readiness with shuttle carts or stacker cranes. Request structural load calculations and deformation test reports, particularly for multi-tier mezzanine configurations.

Production and Customization Capacity

Assess core manufacturing capabilities through the following criteria:

- Minimum facility size of 3,000m² to ensure batch production scalability

- In-house engineering teams capable of CAD-based layout design and dynamic simulation

- On-site processing of critical components: roll-formed uprights, beam connectors, wire mesh decking, and shuttle rail alignment

Cross-reference product listings with customization tags such as adjustable height, layer count, weight rating, and surface treatment (e.g., galvanization).

Transaction and Quality Assurance

Prioritize suppliers with documented on-time delivery rates exceeding 98% and reorder rates above 25%, indicating customer satisfaction and operational reliability. Validate response efficiency (target ≤2 hours) and review historical order volume as a proxy for market trust. When available, request third-party inspection reports or factory audit videos to confirm compliance before placing bulk orders.

What Are the Best Automated Pallet Racking System Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Aceally (Xiamen) Technology Co., Ltd. | Fujian, CN | Stacking Racks & Shelves, Cargo & Storage Equipment | US $100,000+ | 100% | ≤2h | <15% | Material, load capacity, design | 100 units (decking), 20 units (racks) |

| Guangxi Nanhua Jianzhian Integrated Housing Co., Ltd. | Guangxi, CN | Adjustable Steel Shelving, Stacking Racks | US $920,000+ | 98% | ≤2h | 25% | Size, layers, color, weight capacity, mezzanine | 1–20 units |

| VIET-LONG AN MECHANICAL COMPANY LIMITED | Vietnam | ASRS, Radio Shuttle Racks, High-Density Racking | Not disclosed | Not disclosed | ≤2h | Not disclosed | System integration, material density | 5,000 kg (priced per kg) |

| Shenzhen Huaxinda Storage Equipment Co., Ltd. | Guangdong, CN | ASRS, Mobile Shuttle Racking | US $4,000+ | 100% | ≤7h | 33% | Heavy-duty configuration | 10 pieces |

| Gangding Intelligent Equipment (Chongqing) Co., Ltd. | Chongqing, CN | Radio Shuttle Racks, Mechanical Pallet Movers | US $20,000+ | 100% | ≤6h | <15% | Modular design, material specs | 1 kg–1 piece |

Performance Analysis

Guangxi Nanning Jianzhian stands out with the highest online revenue and broadest customization scope, supporting tailored designs for multi-level shelving and mezzanine integration. Despite lower visibility in transaction metrics, VIET-LONG AN offers competitive pricing models based on material weight (from $0.88/kg), ideal for large-scale deployments. Shenzhen Huaxinda demonstrates strong customer retention with a 33% reorder rate, signaling post-sale satisfaction in ASRS implementations. Aceally and Gangding both achieve perfect on-time delivery records, with Gangding offering the lowest MOQs—down to 1 kilogram or single-unit mechanical movers—making them suitable for prototyping or phased installations.

FAQs

How to verify automated pallet racking system supplier reliability?

Cross-check declared certifications with official registries. Request evidence of completed projects, including 3D warehouse layouts and integration diagrams. Evaluate responsiveness and technical depth during initial inquiries—reliable suppliers provide prompt, detailed answers on load dynamics, shuttle compatibility, and installation protocols.

What is the typical lead time for customized systems?

Standard lead times range from 25 to 40 days after design approval. Complex ASRS integrations may require 45–60 days, depending on control system programming and component sourcing. Expedited production is occasionally available for an additional fee.

Can suppliers handle global shipping and customs clearance?

Yes, most established manufacturers offer FOB and CIF shipping terms with documentation support for export compliance. Confirm whether packaging meets ISPM 15 standards for wooden components and if electrical subsystems comply with IEC or NEC codes where applicable.

Do suppliers provide free samples or prototypes?

Sample policies vary. Some suppliers waive fees for full-system buyers or offer paid samples (typically 30–50% of unit cost). For structural components like beams or decking, expect sample costs between $6.60 and $25.99, with lead times of 7–14 days.

How to initiate a custom racking system request?

Submit clear specifications including warehouse dimensions, pallet type (Euro, standard, etc.), load weight per bay, desired automation level (manual, semi-auto, fully automated), and integration requirements (WMS/WCS). Reputable suppliers will return a layout proposal within 5–7 business days and offer virtual walkthroughs of the proposed system.