Automated Racking System

0

0

1/3

1/3

1/3

1/3

CN

CN

1/1

1/1

1/3

1/3

1/1

1/1

1/38

1/38

1/3

1/3

0

0

CN

CN

0

0

1/23

1/23

1/3

1/3

0

0

1/40

1/40

1/3

1/3

1/1

1/1

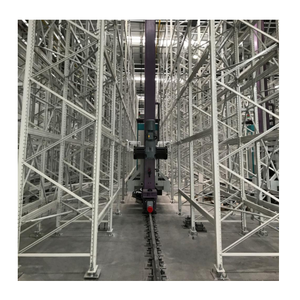

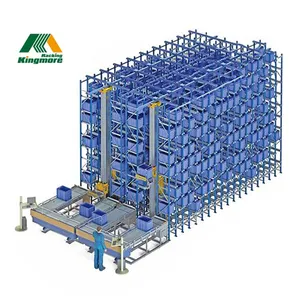

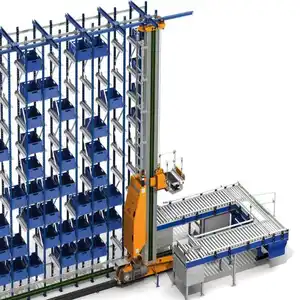

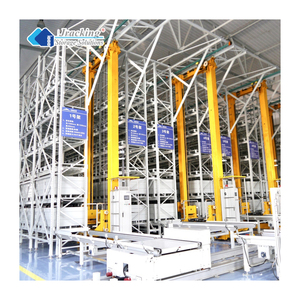

About automated racking system

Where to Find Automated Racking System Suppliers?

China remains the global epicenter for automated racking system manufacturing, with key production clusters concentrated in Guangdong and Fujian provinces. These regions host vertically integrated supply chains combining steel fabrication, structural engineering, and warehouse automation expertise. Guangdong’s Foshan and Dongguan zones specialize in high-density ASRS (Automated Storage and Retrieval Systems), leveraging proximity to Tier-1 logistics hubs for rapid prototyping and export. Fujian-based suppliers, particularly around Xiamen, focus on modular stacking racks with advanced customization capabilities in material finish, load capacity, and integration-ready designs.

The industrial ecosystems support scalable production through co-located component manufacturers, CNC processing centers, and third-party quality auditors within 50km radii. This integration enables lead times averaging 25–40 days for standard configurations and 45–60 days for fully automated systems. Buyers benefit from 15–25% cost advantages over European or North American producers due to lower labor costs, localized raw material access, and optimized factory throughput. The region also supports flexible order volumes—from single-set prototypes to container-scale deployments—making it ideal for both pilot projects and enterprise-level rollouts.

How to Choose Automated Racking System Suppliers?

Procurement decisions should be guided by rigorous evaluation of technical, operational, and transactional criteria:

Technical Compliance and Design Capability

Verify that suppliers demonstrate proficiency in structural engineering standards such as ISO 9001 and EN 15512 for pallet racking safety. For automated systems, confirm compatibility with warehouse management software (WMS) and shuttle/cart integration protocols. Request design drawings, load-test reports, and material certifications (e.g., Q235B/Q345B steel) before order placement.

Production Infrastructure Assessment

Evaluate supplier capacity based on the following benchmarks:

- Minimum factory area exceeding 3,000m² for consistent output

- In-house capabilities in laser cutting, robotic welding, and powder coating

- Dedicated R&D or engineering teams for custom configurations

Cross-reference product listings with on-time delivery performance (target ≥95%) and response time metrics (≤3 hours) to assess operational reliability.

Transaction and Quality Safeguards

Prioritize suppliers offering third-party inspection options and secure payment terms. Analyze reorder rates as an indicator of customer satisfaction—rates above 20% suggest strong post-sale support and product durability. Conduct sample testing to validate layer stability, corrosion resistance (especially for galvanized finishes), and dimensional accuracy against specifications.

What Are the Best Automated Racking System Suppliers?

| Company Name | Location | Verification Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Kimsuk Shelves Co., Ltd. | Guangdong, CN | Multispecialty Supplier | Automatic Warehouse Racks, Cantilever & Multi-tier Platforms | 93% | ≤2h | 21% | US $230,000+ | Material, size, color, layers, graphic, logo, packaging |

| Guangdong Yuzhao Warehousing Equipment Co. Ltd | Guangdong, CN | Not Specified | Stacking Racks & Multi-Level Pallet Systems | 100% | ≤3h | <15% | US $50,000+ | Limited public data |

| Foshan Kingshelving Technology Co., Ltd. | Guangdong, CN | Not Specified | ASRS, High-Density Automatic Racking, Shuttle Systems | 100% | ≤2h | - | - | Material, size, load capacity, structural design |

| Aceally (Xiamen) Technology Co., Ltd. | Fujian, CN | Not Specified | Wire Mesh Decking, Mobile Shuttle Carts, Shelving Systems | 100% | ≤2h | <15% | US $100,000+ | Material, dimensions, labeling, packaging, logo |

| Chongqing Kinghom Warehouse Storage Equipment Co., Ltd. | Chongqing, CN | Custom Manufacturer | ASRS Racking, Heavy-Duty 2/4-Way Outlet Systems | 100% | ≤1h | <15% | US $3,000+ | Size, material, color, logo, configuration, packaging |

Performance Analysis

Guangzhou Kimsuk stands out with a 21% reorder rate and robust customization scope, indicating strong market confidence and after-sales service quality. Despite a slightly lower on-time delivery rate (93%), its high online revenue suggests extensive order volume and export experience. In contrast, Guangdong Yuzhao, Foshan Kingshelving, and Chongqing Kinghom all report 100% on-time delivery, reflecting disciplined production planning—particularly critical for time-sensitive warehouse integrations. Chongqing Kinghom leads in responsiveness (≤1h), offering strategic advantage for urgent RFQs. Suppliers like Foshan Kingshelving specialize in full ASRS solutions priced between $5,394–$9,000 per set, targeting mid-to-large-scale automation projects. Meanwhile, Aceally focuses on component-level supply (e.g., wire mesh decking at $6.60/unit MOQ 100), serving niche retrofitting and modular upgrade needs.

FAQs

How to verify automated racking system supplier reliability?

Cross-check declared certifications with independent audit records. Request evidence of past installations, including project photos, client references, and structural test reports. Assess responsiveness consistency and technical depth in communication as proxies for post-sale support capability.

What is the typical minimum order quantity (MOQ)?

MOQ varies by product type: standard rack sets typically require 1–10 sets; component suppliers (e.g., decking) may require 100–500 units or 500–5,000 kg for bulk material orders. Custom ASRS systems often have a 1-set MOQ due to complexity.

What are common lead times for automated racking systems?

Standard systems ship in 25–35 days after order confirmation. Fully automated ASRS or custom-engineered solutions require 45–60 days, depending on design validation and component sourcing timelines.

Can suppliers provide design and engineering support?

Yes, most established suppliers offer free CAD drawings, load calculations, and layout planning. Custom manufacturers typically provide 3D models within 72 hours and revise designs iteratively based on site requirements.

Are samples available before bulk ordering?

Sample policies vary: some suppliers offer paid samples (cost recoverable against future orders), while others provide small components (e.g., decking panels) at nominal fees. Full-system sampling is rare but possible under NRE agreements for large contracts.