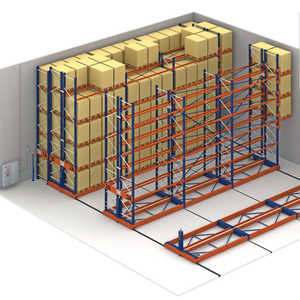

Automated Pallet Storage System

Top sponsor listing

Top sponsor listing

1/1

1/1

1/3

1/3

1/23

1/23

1/23

1/23

CN

CN

1/3

1/3

0

0

1/17

1/17

1/3

1/3

VN

VN

1/35

1/35

CN

CN

1/38

1/38

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/26

1/26

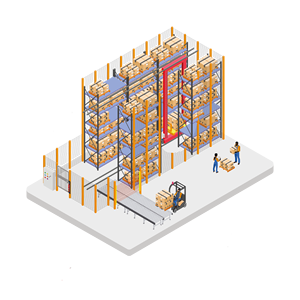

About automated pallet storage system

Where to Find Automated Pallet Storage System Suppliers?

China remains the global epicenter for automated pallet storage system manufacturing, with key production clusters concentrated in Guangdong, Jiangsu, and Shenzhen. These regions host vertically integrated facilities specializing in industrial racking, ASRS (Automated Storage and Retrieval Systems), and smart warehouse solutions. Guangzhou and Nanjing suppliers leverage mature steel processing ecosystems and proximity to port infrastructure, enabling efficient export logistics and reduced material costs by 15–25% compared to Western counterparts.

The industrial hubs support rapid prototyping and scalable production, with many manufacturers operating end-to-end processes—from structural design and CNC fabrication to powder coating and modular assembly. This integration allows lead times as short as 20–35 days for standard configurations, while custom-engineered systems typically require 45–60 days. Buyers benefit from access to technical specialists, certified engineering teams, and component suppliers within tight geographic radii, enhancing coordination and quality control across the supply chain.

How to Choose Automated Pallet Storage System Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Engineering & Customization Capability

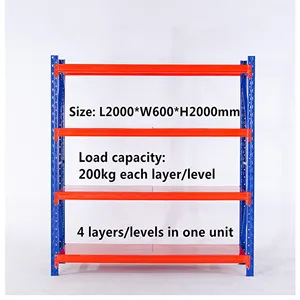

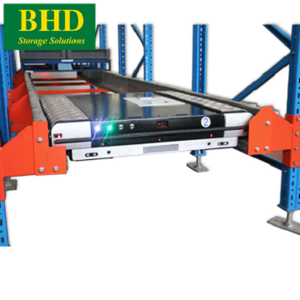

Verify that suppliers offer detailed customization options including load capacity (ranging from 500kg to over 5,000kg per level), beam length, upright dimensions, decking material, layer count, and integration with shuttle or mezzanine elevator systems. Leading manufacturers provide CAD layout drawings, 3D assembly models, and structural calculations upon request. Confirm in-house design teams capable of adapting to warehouse footprint constraints and automation protocols.

Quality Management & Compliance

Prioritize suppliers with ISO-certified production systems and documented quality assurance procedures. While explicit certification data is limited in available profiles, consistent on-time delivery rates above 97% and repeat order rates exceeding 25% serve as indirect indicators of process reliability. Evaluate use of high-tensile steel, precision welding techniques, and corrosion-resistant powder coating for long-term durability in industrial environments.

Production Capacity & Responsiveness

Assess operational scale through response time, reorder rate, and online revenue metrics:

- Response time ≤3 hours: Indicates strong customer service infrastructure (e.g., Guangzhou Maobang, Heda)

- Reorder rate >30%: Suggests high client retention and product satisfaction (e.g., Shenzhen Huaxinda, Nanjing Kingmore)

- On-time delivery at 100%: Demonstrates consistent logistical execution (held by three out of five profiled suppliers)

Procurement Terms & Risk Mitigation

Minimum Order Quantities (MOQ) vary significantly—some suppliers quote by piece (e.g., 10–20 units), while others price per kilogram (100–10,000 kg thresholds). Unit pricing ranges from $0.95 to $235 depending on complexity and materials. For high-value orders, implement third-party inspection protocols before shipment and consider staged payments linked to production milestones. Request sample units or site visits to validate structural integrity and installation feasibility prior to full-scale deployment.

What Are the Best Automated Pallet Storage System Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

| Guangzhou Maobang Storage Equipment Co., Ltd. | Stacking Racks & Shelves, Cargo & Storage Equipment, Supermarket Shelves | 92% | 24% | ≤3h | US $1,400,000+ | Yes – color, thickness, load capacity, layout, guardrails, beam size, decking, stairs, labeling | Custom Manufacturer |

| Shenzhen Huaxinda Storage Equipment Co., Ltd. | Stacking Racks & Shelves | 100% | 33% | ≤7h | US $4,000+ | Limited public detail | - |

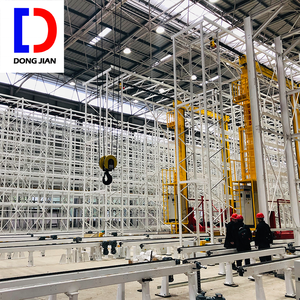

| Nanjing Dongjian Racking Manufacturing Co., Ltd. | Cargo & Storage Equipment, Stacking Racks & Shelves, Storage Cages | 100% | <15% | ≤1h | US $110,000+ | Inferred via product variants (adjustable vertical, multi-deep shuttle) | - |

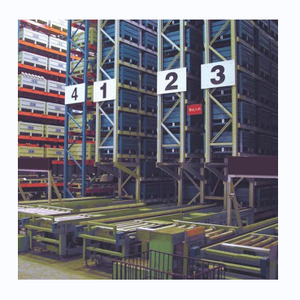

| Nanjing Kingmore Logistics Equipment Manufacturing Co., Ltd. | ASRS, Radio Shuttle Racks, Gravity Flow Racking | 100% | 33% | ≤11h | US $130,000+ | Not explicitly stated | Multispecialty Supplier |

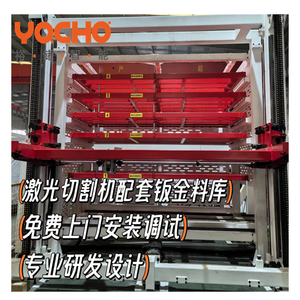

| Guangzhou Heda Intelligent Warehousing Equipment Co., Ltd. | Automated Shelving, Radio Shuttle Pallet Racks, Cantilever Racks | 100% | 25% | ≤3h | US $90,000+ | Yes – color, material, size, logo, packaging, graphic, bolted dimensions | Custom Manufacturer |

Performance Analysis

Guangzhou Maobang stands out for extensive customization breadth and the highest reported online revenue, indicating robust market presence despite a slightly lower on-time delivery rate (92%). Shenzhen Huaxinda and Nanjing Kingmore demonstrate strong buyer loyalty with 33% reorder rates, suggesting high post-purchase satisfaction. Nanjing Dongjian excels in responsiveness (≤1h) and achieves perfect on-time fulfillment, though its lower reorder rate may indicate niche positioning or newer market entry. Guangzhou Heda combines fast response times with dedicated customization capabilities, making it well-suited for tailored automated warehousing projects.

FAQs

What certifications should automated pallet storage system suppliers have?

While not all suppliers list certifications explicitly, ISO 9001 compliance is recommended for quality management. Structural designs should adhere to international load-bearing standards (e.g., FEM, ANSI/MH16.1). For EU markets, CE marking and conformity with mechanical safety directives are essential.

What is the typical MOQ and pricing structure?

MOQs range from 10 pieces for finished rack units to 100–10,000 kilograms for fabricated components. Pricing varies from $0.95/kg to $235/unit based on automation level, material grade, and configuration complexity. Bulk orders often unlock tiered discounts and extended warranty terms.

Can suppliers integrate systems with warehouse management software (WMS)?

Advanced suppliers support integration with WMS and WCS (Warehouse Control Systems), particularly those offering ASRS and radio shuttle technology. Confirm compatibility with existing ERP platforms during technical scoping.

Do manufacturers provide installation support?

Many offer engineering drawings, assembly instructions, and remote guidance. For complex deployments, on-site supervision or turnkey installation services may be available at additional cost—request details during quotation.

How to verify structural integrity and load capacity claims?

Demand finite element analysis (FEA) reports or test certificates validating maximum load ratings. Request references or case studies from similar industrial applications. Independent third-party inspections can further mitigate risk prior to acceptance.