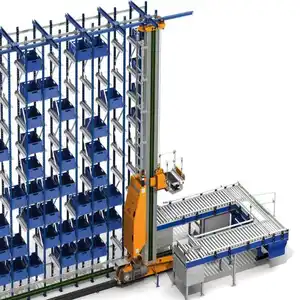

Automated Warehouse Racking System

Top sponsor listing

Top sponsor listing

CN

CN

1/23

1/23

1/17

1/17

1/38

1/38

1/20

1/20

1/24

1/24

1/40

1/40

1/23

1/23

CN

CN

1/15

1/15

CN

CN

1/13

1/13

CN

CN

1/22

1/22

About automated warehouse racking system

Where to Find Automated Warehouse Racking System Suppliers?

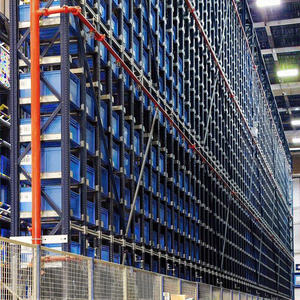

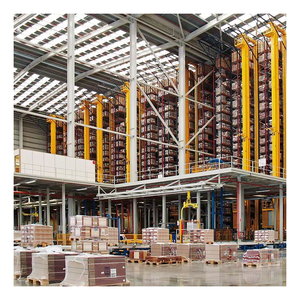

China remains the global hub for automated warehouse racking system manufacturing, with key production clusters in Guangdong, Guangxi, Hebei, and Guangzhou. These regions host vertically integrated facilities that combine structural engineering, material processing, and intelligent logistics integration under one supply chain. Guangdong and Guangxi specialize in high-volume production of modular steel racking systems, leveraging proximity to coastal ports for efficient export logistics. Hebei’s metal fabrication expertise supports heavy-duty load-bearing structures, while Guangzhou has emerged as a center for smart warehousing solutions integrating AGVs and shuttle-based automation.

Suppliers in these clusters benefit from localized access to Q235B and Q345 steel, powder-coated laminates, and precision-cut tubing, reducing material lead times by 15–25% compared to offshore alternatives. Integrated design-to-assembly workflows enable rapid prototyping and customization, with average production cycles ranging from 20–45 days depending on system complexity. Buyers gain access to scalable manufacturing ecosystems capable of fulfilling both standard configurations and engineered-to-order automated storage and retrieval systems (AS/RS).

How to Choose Automated Warehouse Racking System Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Engineering & Customization Capability

Assess suppliers’ ability to deliver tailored solutions based on floor load capacity, aisle width, panel height, and integration requirements for AGVs or stacker cranes. Verified manufacturers offer detailed design support including 2D/3D layout drawings, load distribution analysis, and structural simulations. Key customization parameters include tray type (pallet, carton flow, gravity roller), frame material (round/square tube), layer adjustability, guard rail specifications, and labeling options.

Production and Quality Assurance

Prioritize suppliers demonstrating measurable performance metrics:

- On-time delivery rate exceeding 95%

- Response time under 4 hours (ideally ≤2h)

- In-house production control with welding, punching, and coating capabilities

- Documented quality checks for dimensional accuracy, weld integrity, and coating thickness

While ISO 9001 certification is not explicitly stated in available data, consistent reorder rates (up to 50%) and high on-time delivery (100% among top-tier suppliers) indicate robust internal quality management systems.

Procurement and Risk Mitigation

Evaluate transactional reliability through verifiable order history and fulfillment consistency. Favor suppliers with transparent pricing models, clear minimum order quantities (MOQs), and participation in secure payment frameworks. Request sample units to validate build quality, assembly ease, and component durability before scaling procurement. Confirm packaging methods and export readiness, particularly for international shipments requiring CE or ANSI compliance documentation.

What Are the Best Automated Warehouse Racking System Suppliers?

| Company Name | Main Products | Customization Options | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangdong Sunli Intelligent Logistics Equipment Co., Ltd. | AS/RS Racking, Pallet Storage, Heavy-Duty Steel Racks | Layout, logo, packaging, dimensions | US $360,000+ | 100% | 50% | ≤2h | 3,000–5,000 sqm | $5–600 |

| Guangxi Nanning Jianzhian Integrated Housing Co., Ltd. | Stacking Racks, Adjustable Steel Shelves, Mezzanine Systems | Color, size, layers, load capacity, wheels, legs | US $960,000+ | 98% | 30% | ≤1h | 1–2 units | $15–24.69 |

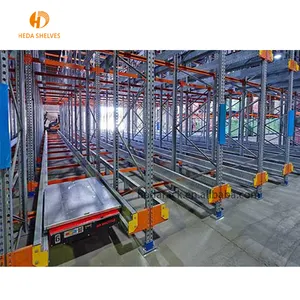

| Guangzhou Heda Intelligent Warehousing Equipment Co., Ltd. | Radio Shuttle Pallet Racks, Carton Flow Systems, AGV-Compatible Racks | Material, color, size, logo, packaging | US $60,000+ | 100% | 25% | ≤4h | 20 pieces | $25–45 |

| Hebei Woke Metal Products Co., Ltd. | RGV Robotic Retrieval, Stacker Cranes, Narrow-Aisle Systems | Limited customization (primarily system integration) | Not specified | 100% | Not available | ≤4h | 1 set / 1,000 kg | $1,500–$99,999 |

| Guangdong Kimsuk Storage Equipment Manufacturing Co., Ltd. | Multi-Layer Shelves, Removable Racks, Load-Bearing Designs | Material, finish, dimensions, load capacity, assembly style | US $1,500,000+ | 95% | 22% | ≤2h | Not specified | Not listed |

Performance Analysis

Guangdong Sunli stands out with the highest reorder rate (50%), indicating strong customer satisfaction and repeat business, supported by full customization and large-scale project capability. Guangxi Nanning Jianzhian offers the fastest response time (≤1h) and competitive per-unit pricing, making it suitable for agile procurement cycles. Guangzhou Heda and Hebei Woke focus on higher-end automation integration, reflected in elevated price points and specialized product offerings such as radio shuttle and robotic retrieval systems. Despite limited reorder data, Hebei Woke maintains 100% on-time delivery, suggesting reliable execution for complex AS/RS deployments. Guangdong Kimsuk leads in online revenue volume, signaling extensive market reach and production scalability.

FAQs

How to verify automated warehouse racking system supplier reliability?

Cross-reference on-time delivery records, reorder rates, and response times with direct communication tests. Request evidence of past projects, CAD design samples, and material test reports. For critical applications, conduct virtual factory audits to assess production lines, welding stations, and quality inspection protocols.

What is the typical lead time for customized systems?

Standard orders require 20–30 days; engineered systems with AGV or shuttle integration may take 45–60 days depending on design validation and component sourcing. Prototypes can typically be delivered within 3–4 weeks after finalizing technical drawings.

Can suppliers accommodate low-volume or sample orders?

Yes, several suppliers accept small MOQs—from 1 unit to 20 pieces—enabling buyers to evaluate quality before committing to bulk purchases. Sample costs vary but generally reflect material and processing expenses without setup surcharges.

Do manufacturers support international shipping and compliance?

Established exporters provide FOB and CIF shipping terms with containerized packing suitable for sea freight. While specific certifications are not listed, suppliers with export experience can typically generate CE-marking documentation or structural compliance reports upon request for customs clearance.

How to initiate a customization request?

Submit detailed specifications including required load capacity (per level and total), racking dimensions (height, depth, width), floor bearing conditions, desired automation interface (e.g., AGV guidance, shuttle compatibility), and environmental factors (indoor/outdoor, humidity). Reputable suppliers respond with layout proposals and structural calculations within 72 hours.