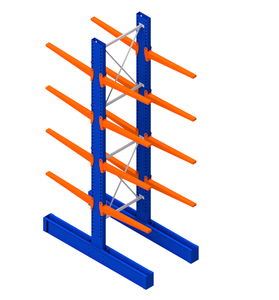

Warehouse Racking System

Top sponsor listing

Top sponsor listing

VN

VN

CN

CN

About warehouse racking system

Where to Find Warehouse Racking System Suppliers?

China remains the dominant hub for warehouse racking system manufacturing, with key industrial clusters concentrated in Guangdong and Gansu provinces. These regions host vertically integrated production ecosystems that combine steel processing, structural design, and logistics infrastructure to support global export demand. Guangzhou-based suppliers leverage proximity to major ports, enabling faster container dispatches and reduced freight costs for international buyers. Meanwhile, inland manufacturers like those in Gansu benefit from lower labor and operational expenses, contributing to competitive pricing without compromising structural integrity.

The sector is characterized by high specialization in cold-formed steel fabrication and modular assembly techniques, allowing for scalable production of selective, pallet, mezzanine, and automated storage systems. Suppliers typically operate multi-process facilities capable of cutting, punching, roll-forming, welding, and powder coating—all under one roof. This integration supports lead times averaging 20–35 days for standard configurations, with bulk orders benefiting from economies of scale. Customization capabilities are widespread, including load capacity adjustments (ranging from light-duty shelving to heavy-duty industrial racks exceeding 4,000 kg per level), material thickness variation, color coding, and CAD-based layout planning.

How to Choose Warehouse Racking System Suppliers?

Selecting a reliable supplier requires due diligence across technical, operational, and transactional dimensions:

Structural and Material Specifications

Verify use of high-tensile Q235 or Q345 steel, which ensures compliance with international load-bearing standards. Confirm available customization parameters such as upright size, beam length, deck type (steel, timber, or composite), and layer count. Reputable suppliers provide detailed engineering drawings, assembly instructions, and load capacity charts per bay configuration.

Quality Assurance & Compliance

Prioritize suppliers with documented quality control processes. While formal ISO 9001 certification may not always be listed, consistent on-time delivery rates (>94%) and verifiable reorder rates indicate operational reliability. For European or North American markets, ensure compatibility with EN 15635 or RMI (Rack Manufacturers Institute) safety guidelines, particularly regarding seismic stability and guardrail integration.

Production Capacity and Responsiveness

Evaluate supplier capability through measurable indicators:

- Facility output reflected in product listings (e.g., >1,000 SKUs suggest large-scale operations)

- Response time ≤3 hours indicates dedicated sales and engineering support

- On-time delivery performance ≥94% correlates with stable supply chain management

- Reorder rates above 20% reflect customer satisfaction and product durability

Cross-reference these metrics with customization depth—such as options for staircases, elevators, labeling, packaging methods, and graphic markings—to assess flexibility for project-specific requirements.

What Are the Best Warehouse Racking System Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

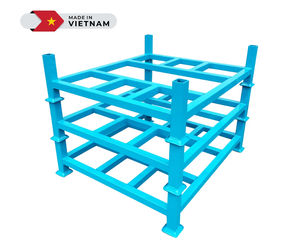

| Guangzhou Maobang Storage Equipment Co., Ltd. | Stacking Racks & Shelves (1392) | 94% | 25% | ≤3h | US $1.3M+ | Color, thickness, layers, load capacity, decking, layout, logo, guardrails, powder coating, beam size, upright dimensions | Kilogram-level and set-based MOQs |

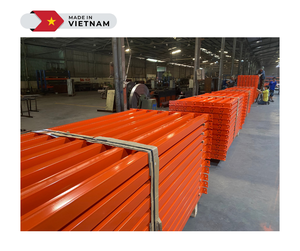

| GUANGMING VIET NAM COMPANY LIMITED | Stacking Racks & Shelves (1090) | - | - | ≤2h | - | Limited data; price quoted per kg suggests bulk raw component focus | As low as 1kg |

| Gansu Sanyang Storage Equipment Manufacturing Co., Ltd. | Industrial storage systems (5+ active SKUs) | 100% | <15% | ≤5h | US $100K+ | Color, material, size, logo, packaging, graphic design | 10-set minimum for finished units |

| Guangzhou Kimsuk Shelves Co., Ltd. | Storage racking (multiple SKUs) | 94% | 18% | ≤2h | US $250K+ | Dimensions, capacity, color, style, graphic labeling, assembly drawings | 1 set or 1kg depending on product |

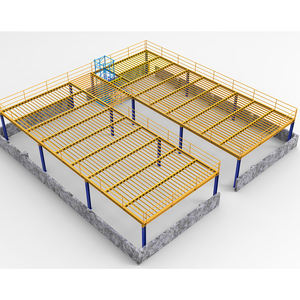

| Shenzhen Huaxinda Storage Equipment Co., Ltd. | Stacking Racks & Shelves (58) | 100% | 22% | ≤7h | US $4K+ | ASRS integration, mezzanine platforms, shuttle racking, light/heavy-duty variants | Single piece to 10-piece lots |

Performance Analysis

Guangzhou Maobang leads in scale and customization breadth, supported by strong reorder volume and high online revenue, indicating market trust and repeat business. Gansu Sanyang stands out with perfect on-time delivery and structured packaging options, though its lower reorder rate suggests room for improvement in post-sale engagement. Shenzhen Huaxinda specializes in advanced solutions like ASRS (Automated Storage and Retrieval Systems) and shuttle racking, catering to smart warehouse integrators despite limited public financial data. Guangzhou Kimsuk offers balanced responsiveness and moderate customization, suitable for mid-tier commercial applications. GUANGMING VIET NAM focuses on component-level supply with minimal order thresholds, ideal for buyers integrating racking into broader equipment lines.

FAQs

How to verify warehouse racking system supplier reliability?

Assess consistency in delivery performance, response speed, and product listing accuracy. Request material test reports (MTRs) for steel components and inquire about anti-corrosion treatments like galvanization or powder coating. Review available product images for weld quality, surface finish, and labeling clarity. Where possible, request third-party inspection services prior to shipment.

What is the typical MOQ and pricing structure?

MOQ varies: some suppliers offer per-set orders starting at 1–10 sets, while others quote per kilogram (from 1kg to 9,999kg minimums). Unit prices range from $0.70/kg for raw materials to $25–$100/set for fully assembled shelving, with premium systems (e.g., mezzanines or automated racks) exceeding $200/unit. Bulk discounts are commonly available beyond 500 sets or 10,000kg.

Can suppliers accommodate custom designs?

Yes, most suppliers support dimensional modifications, load capacity tuning, color selection, logo printing, and integration of accessories (e.g., handrails, stairs, ramps, elevators). Provide CAD layouts or operational requirements to receive accurate quotes and structural validation.

What are common lead times and shipping options?

Standard orders take 20–35 days for production. Sea freight remains optimal for full-container loads (20ft or 40ft), with FOB terms prevalent. Air freight is viable only for small samples or urgent spare parts due to weight constraints.

Do suppliers provide installation support or technical documentation?

Many offer free assembly drawings, layout plans, and instructional videos. Some include bilingual manuals or site supervision services upon request, especially for large-scale deployments. Confirm availability before finalizing contracts.