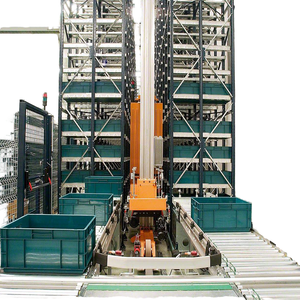

Automated Pallet Storage And Retrieval System

1/3

1/3

CN

CN

CN

CN

1/40

1/40

1/38

1/38

1/3

1/3

1/3

1/3

0

0

0

0

1/17

1/17

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/26

1/26

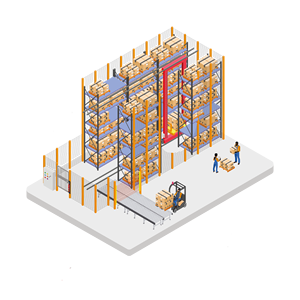

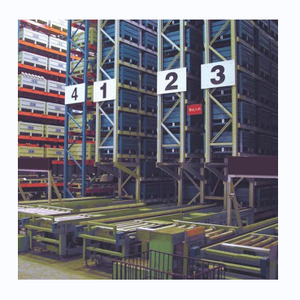

About automated pallet storage and retrieval system

Where to Find Automated Pallet Storage and Retrieval System Suppliers?

China remains the global hub for automated pallet storage and retrieval system manufacturing, with key production clusters in Fujian, Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, structural steel fabrication, and intelligent logistics control systems under one supply chain. Xiamen and Guangzhou serve as primary export centers due to their proximity to major ports and established networks of component suppliers, enabling efficient assembly and rapid deployment of high-density warehouse automation solutions.

The concentration of technical expertise and supporting infrastructure allows manufacturers to offer scalable production capacity, with leading suppliers operating facilities exceeding 10,000m². This enables fast turnaround on both standard configurations and engineered-to-order systems. Buyers benefit from localized access to raw materials such as galvanized steel, load-bearing mesh decking, and shuttle cart components, reducing material lead times by up to 30%. Average production cycles range from 25–45 days depending on customization level, with many suppliers maintaining modular design libraries to accelerate project quoting and implementation.

How to Choose Automated Pallet Storage and Retrieval System Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Design

Verify adherence to international material and safety standards, including ISO 9001 for quality management and CE marking where applicable. For automated systems integrating motorized shuttles or robotic stackers, confirm compliance with electrical safety (IEC 60204) and mechanical handling regulations. Request detailed engineering drawings, load capacity calculations, and dynamic simulation reports—especially for high-bay installations exceeding 10 meters in height.

Production Capability Assessment

Evaluate core manufacturing competencies through the following criteria:

- Minimum factory area of 5,000m² to support full-scale fabrication and testing

- In-house capabilities in CNC cutting, robotic welding, powder coating, and galvanization

- Dedicated R&D teams for AS/RS software integration and shuttle system optimization

Cross-reference supplier claims with verifiable performance metrics such as on-time delivery rates (>98%) and reorder frequency.

Customization & Integration Readiness

Confirm availability of tailored solutions including rack configuration (FIFO/LIFO), shuttle navigation protocols, WMS/WCS interface compatibility, and load adaptability (pallet types, weights up to 2,000kg). Leading suppliers provide 3D modeling and layout simulations within 72 hours of inquiry to validate space utilization and throughput projections.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services for initial orders. Prioritize suppliers with transparent transaction histories, documented after-sales service records, and multilingual technical support. Pre-shipment inspection (PSI) should be mandatory for first-time partnerships, with third-party verification recommended for container-sized shipments.

What Are the Best Automated Pallet Storage and Retrieval System Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

| Aceally (Xiamen) Technology Co., Ltd. | Fujian, CN | Stacking Racks & Shelves (541), Cargo & Storage Equipment (409) | US $130,000+ | 100% | ≤2h | <15% | Not specified | $660 (100 units @ $6.60) |

| Guangzhou Heda Warehouse Equipment Co., Ltd. | Guangdong, CN | Four-Way Radio Shuttle Racks, Intelligent Pallet Systems | US $50,000+ | 100% | ≤4h | 42% | Color, material, size, logo, packaging, graphic | $580 (10 sets @ $58) |

| Beijing Dongfang Guokai Industrial Equipment Co., Ltd. Hangzhou Branch | Zhejiang, CN | ASRS, Heavy-Duty Automated Systems, Warehouse Robots | US $600,000+ | 100% | ≤2h | 20% | Material, size, capacity, galvanizing, system integration, safety lock, frame design | $10,800 (1 set) |

| Nanjing Jinhui Storage Equipment Co., Ltd. | Jiangsu, CN | ASRS Racking, Smart Warehousing Structures | US $2,400,000+ | 100% | ≤2h | 16% | Racking type, material, load capacity, beam length, mezzanine options, layout design | $880 (1,000 kg @ $0.88/kg) |

| Guangdong Sunli Intelligent Logistics Equipment Co., Ltd. | Guangdong, CN | Automatic Stacker Cranes, AS/RS Pallet Racks | US $360,000+ | 100% | ≤4h | 50% | Layout design, logo, packaging, catalog, dimensions | $250 (5,000 kg @ $0.05/kg) |

Performance Analysis

Nanjing Jinhui leads in revenue scale and offers competitive per-kilogram pricing, indicating strong OEM/export orientation and cost efficiency in large-volume racking projects. Guangdong Sunli stands out with a 50% reorder rate—the highest among listed suppliers—suggesting robust customer satisfaction and repeat engagement, likely driven by responsive customization and system integration support. Beijing Dongfang Guokai specializes in fully automated turnkey systems priced above $10,000/set, targeting mid-to-high-end smart warehouses requiring precision robotics and WMS connectivity.

Guangzhou Heda focuses on four-way shuttle technology with consistent mid-range pricing ($58–78/set), ideal for high-density storage applications requiring deep-lane access without rail dependency. Aceally (Xiamen) offers entry-level wire mesh decking components at low MOQs, positioning it as a component supplier rather than a full-system integrator. All top-tier suppliers maintain 100% on-time delivery records, underscoring reliability in fulfillment, while response times under 4 hours ensure timely communication during procurement cycles.

FAQs

How to verify automated storage and retrieval system supplier reliability?

Cross-check quality certifications (ISO 9001, CE) with issuing bodies and request audit trails for material sourcing and weld integrity testing. Review verifiable customer feedback focusing on system uptime, software stability, and post-installation technical support. Conduct virtual factory audits to observe CNC lines, load-testing procedures, and final assembly workflows.

What is the typical sampling timeline for AS/RS components?

Standard rack samples take 10–15 days to produce. Fully automated shuttle carts or stacker cranes require 25–35 days due to electronic integration and calibration. Add 7–14 days for international air freight. Prototypes for custom configurations are typically delivered within 4–6 weeks after design approval.

Can suppliers ship automated storage systems globally?

Yes, most suppliers have export experience and manage FOB, CIF, and DDP shipping terms. They coordinate disassembly, crating, and container loading for sea freight, which is optimal for full warehouse deployments. Confirm compliance with local building codes and seismic requirements prior to shipment.

Do suppliers offer free samples?

Sample policies vary. Component suppliers may waive fees for small parts (e.g., wire decking) if followed by volume orders. For complex subsystems like shuttle carts, expect to pay 30–70% of unit cost, refundable upon order placement exceeding predefined thresholds (e.g., 10+ sets).

How to initiate customization requests?

Submit detailed specifications including pallet dimensions (1200x1000mm, EUR, etc.), load weight (800–2000kg), aisle height (6–15m), desired throughput (pallets/hour), and warehouse management system interface (Modbus, TCP/IP, MQTT). Reputable suppliers respond with layout proposals and 3D models within three business days.