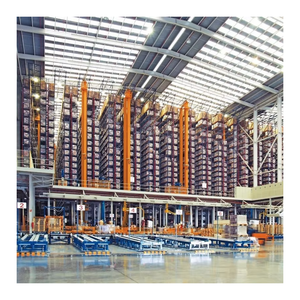

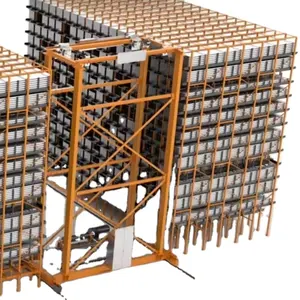

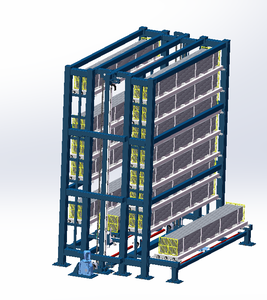

Automated Storage And Retrieval Systems

1/24

1/24

0

0

1/1

1/1

1/3

1/3

1/3

1/3

1/17

1/17

0

0

1/3

1/3

CN

CN

1/1

1/1

1/38

1/38

0

0

1/3

1/3

CN

CN

1/3

1/3

CN

CN

1/73

1/73

CN

CN

1/3

1/3

1/3

1/3

About automated storage and retrieval systems

Where to Find Automated Storage and Retrieval Systems Suppliers?

China remains the global hub for automated storage and retrieval systems (ASRS) manufacturing, with key production clusters in Henan, Anhui, and Guangdong provinces. These regions host vertically integrated facilities that combine structural engineering, precision machining, and control system integration under one supply chain. The concentration of steel processing plants, CNC fabrication units, and industrial automation specialists within 50km radii enables rapid prototyping and scalable production.

Suppliers in Luoyang (Henan) and Hefei (Anhui) leverage proximity to raw material sources, reducing input costs by up to 18% compared to non-integrated markets. Meanwhile, Guangzhou-based manufacturers specialize in high-capacity robotic ASRS units, integrating servo-driven shuttles and warehouse management software. This regional specialization allows buyers to source both modular racking subsystems and turnkey automated warehouses from a single ecosystem, with average lead times ranging from 25–45 days depending on customization level.

How to Choose Automated Storage and Retrieval Systems Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Structural Compliance

Verify adherence to international load-bearing standards such as FEM 10.2.02 or ANSI/MH27.1 for rack integrity. For fully automated systems, confirm integration capabilities with WMS/WCS platforms and compliance with electrical safety norms (e.g., CE marking for EU shipments). Request detailed specifications including dynamic load capacity, deflection tolerance, and cycle time performance for shuttle systems.

Production and Customization Capacity

Assess supplier infrastructure through the following indicators:

- Minimum factory area exceeding 3,000m² for large-scale ASRS fabrication

- In-house capabilities in cold-rolled steel forming, powder coating, and robotic welding

- Design engineering support for layout optimization, seismic zone adaptation, and clearance constraints

Cross-reference product listings with customization tags—such as adjustable shelf spacing, epoxy-coated tiers, or RFID-enabled pallet positions—to validate flexibility.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality management systems (ISO 9001 preferred). Analyze on-time delivery rates above 95% and response times under 5 hours as proxies for operational reliability. Utilize secure payment mechanisms and require pre-shipment inspection protocols, especially for high-value robotic cells priced over $10,000 per unit.

What Are the Best Automated Storage and Retrieval Systems Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Flexibility | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Anhui Rongda Intelligent Equipment Manufacturing Co., Ltd. | Anhui, CN | ASRS Racking, Automated Storage Systems | US $130,000+ | 100% | ≤2h | 100% | 1000kg | Yes |

| Guangzhou Eyda Storage Equipment Co., Ltd. | Guangdong, CN | Fully Automated Warehouse Robots, CTU Systems | US $230,000+ | 100% | ≤2h | 30% | 1 set / 100kg | Yes |

| Aceally (Xiamen) Technology Co., Ltd. | Fujian, CN | Wire Mesh Decking, Mobile Shuttle Carts | US $130,000+ | 100% | ≤2h | <15% | 100 units / 1 pc | Limited |

| Luoyang Morgie Electronic Commerce Co., Ltd. | Henan, CN | Heavy-Duty Industrial Racks, Multi-Layer Shelves | US $540,000+ | 95% | ≤5h | <15% | 20–1000 pcs/kg | Extensive |

| AD RACKING STORAGE SYSTEMS PTE LTD | Singapore | Customized Automatic Pallet Racks, OEM Solutions | Data Unavailable | Not Reported | ≤3h | Not Reported | 1 set | Yes |

Performance Analysis

Anhui Rongda stands out with a perfect reorder rate and consistent $0.90/kg pricing, indicating strong customer retention and cost efficiency in racking production. Guangzhou Eyda offers higher-end solutions, including robotic unit-load systems starting at $10,000/set, backed by full delivery reliability and diversified revenue streams. Luoyang Morgie demonstrates extensive customization depth—from load capacity to graphic labeling—though its lower reorder rate suggests room for service improvement. AD RACKING provides the lowest MOQs (down to 1 set), making it suitable for pilot deployments or niche configurations despite limited verifiable performance data.

FAQs

How to verify ASRS supplier reliability?

Cross-check declared certifications with official registries. Request evidence of past installations, including site photos or reference clients. Evaluate responsiveness consistency and technical documentation completeness during initial inquiries.

What is the typical MOQ for automated storage systems?

Modular rack components are often sold by weight (e.g., 100–1000kg MOQ), while complete robotic shuttles or stacker cranes typically require a minimum order of 1 set. Some suppliers offer sample units for validation at partial cost recovery.

Do suppliers support custom engineering designs?

Yes, leading manufacturers provide end-to-end design services, including 3D modeling, load simulation, and WMS interface development. Custom parameters such as aisle width, pick frequency, and earthquake resistance can be incorporated upon request.

What materials are commonly used in ASRS construction?

Cold-rolled steel is standard for upright frames and beams, often galvanized or epoxy-coated for corrosion resistance. Load-bearing components undergo stress testing to ensure deflection remains below 1/200 of span length under maximum rated load.

Are robotic ASRS units plug-and-play?

Most systems require site-specific configuration and integration with existing warehouse controls. Suppliers typically provide commissioning support, though full automation deployment may involve on-site technician visits and software tuning.