Automated Storage And Retrieval System Companies

Top sponsor listing

Top sponsor listing

CN

CN

1/38

1/38

CN

CN

1/22

1/22

CN

CN

1/45

1/45

1/39

1/39

1/23

1/23

1/26

1/26

CN

CN

1/15

1/15

1/38

1/38

CN

CN

CN

CN

1/40

1/40

1/38

1/38

1/14

1/14

About automated storage and retrieval system companies

Where to Find Automated Storage and Retrieval System Companies?

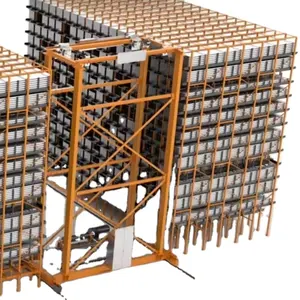

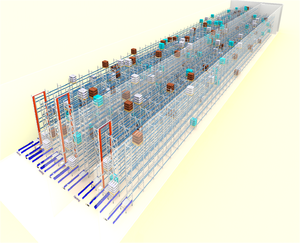

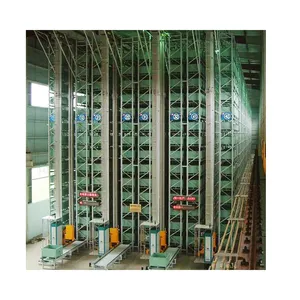

China remains a central hub for automated storage and retrieval system (ASRS) manufacturing, with key production clusters concentrated in Jiangsu, Guangdong, and Shandong provinces. These regions host vertically integrated supply chains specializing in intelligent logistics infrastructure, combining structural steel fabrication, automation engineering, and warehouse integration expertise. Jiangsu province, in particular, is home to over 40% of China’s ASRS manufacturers, supported by advanced metalworking facilities and proximity to major port logistics hubs like Shanghai and Nanjing.

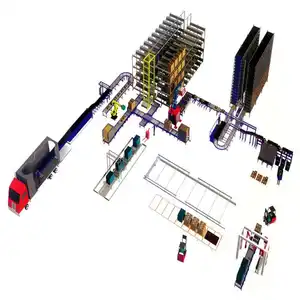

The industrial ecosystem enables streamlined production cycles—from raw material processing to final system assembly—within tightly coordinated geographic zones. Suppliers benefit from localized access to high-tensile steel, CNC machining centers, and control system integrators, reducing component lead times by up to 25%. Buyers gain operational advantages including faster project turnaround (average delivery 30–60 days), scalable production capacity, and cost efficiency driven by competitive labor and materials sourcing. The region supports both standardized solutions and engineered-to-order systems for high-density warehousing, cold storage, and e-commerce fulfillment applications.

How to Choose Automated Storage and Retrieval System Companies?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Engineering & Customization Capability

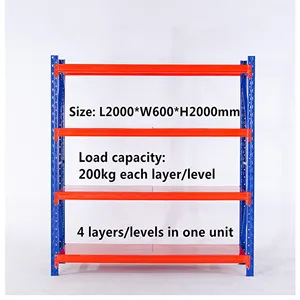

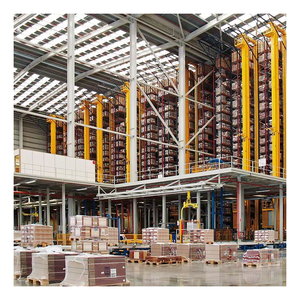

Assess suppliers’ ability to deliver tailored configurations based on load capacity (ranging from 500kg to 5,000kg per pallet), beam length, upright dimensions, and mezzanine integration. Key customization parameters include powder-coated finishes, guardrail placement, staircase layout, and integration with warehouse management systems (WMS). Confirm design support via detailed CAD drawings, 3D modeling, and structural load simulations prior to order confirmation.

Production Infrastructure Verification

Prioritize manufacturers with documented engineering teams and in-house fabrication capabilities. Critical indicators include:

- Minimum factory area exceeding 5,000m² for large-scale projects

- In-house CNC cutting, welding, and surface treatment lines

- Dedicated quality control checkpoints for rack integrity, bolt tolerance, and lifting mechanism calibration

Cross-reference facility size with online revenue metrics and on-time delivery performance to assess scalability and reliability.

Quality Assurance & Compliance

While formal ISO 9001 certification is not universally listed, evaluate adherence to structural safety standards through material test reports (MTRs), load-bearing validation, and corrosion resistance specifications. For export markets, verify compliance with regional building codes and racking safety guidelines such as FEM 10.2.02 or ANSI MH16.1. Request documentation on powder coating thickness, decking material strength, and seismic rating compatibility where applicable.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with milestone deliveries. Analyze supplier responsiveness (target ≤3 hours), historical on-time delivery rates (ideal ≥97%), and reorder frequency to gauge service consistency. Pre-shipment inspections and third-party quality audits are recommended for orders exceeding five sets or custom-engineered installations.

What Are the Best Automated Storage and Retrieval System Companies?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Scope | Min. Order Terms |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Maobang Storage Equipment Co., Ltd. | Guangdong, CN | Stacking Racks & Shelves, Pallets, Mezzanine Systems | 94% | ≤3h | 25% | US $1,000,000+ | Color, layer count, load capacity, guardrails, beam dimensions, layout, decking material, packaging labels | Multiple product units; specific MOQ not disclosed |

| Qingdao Maoyuan Parking Equipment Manufacturing Co., Ltd. | Shandong, CN | Automated Bin Box Stacker, High-Density Steel Bunker Racks | 100% | ≤3h | - | - | Color, material, size, logo, graphic labeling, packaging method | $57,142.86–85,714.29; Min. order: 10 sets |

| Jiangsu Nova Intelligent Logistics Equipment Co., Ltd. | Jiangsu, CN | Heavy-Duty ASRS, Material Box Racks, Intelligent Automatic Systems | 100% | ≤11h | - | US $10,000+ | Color, material, size, logo, packaging, graphic elements | $0.80/kg; Min. order: 2,000 kilograms |

| Jiangsu Xinzhongya Intelligent Logistics Equipment Manufacturing Co., Ltd. | Jiangsu, CN | Pallet Shuttle Systems, Bolted Light-Duty Racks, Radio-Controlled ASRS | 66% | ≤3h | <15% | US $130,000+ | Floor load, wire mesh type, beam dimensions, logo, layout, decking material, height, footprint color | $1.38–1.42/kg; Min. order: 10,000 kg |

| Nanjing Ebil Metal Products Co., Ltd. | Jiangsu, CN | Automated Racking Systems, Pallet Racks, Rack-Supported Buildings | 100% | ≤2h | <15% | US $360,000+ | Load capacity, upright adjustment, shelf layers, corrosion protection, side guards, arm length, WMS integration | $11,000–12,000/set; Min. order: 1 set (varies by product) |

Performance Analysis

Qingdao Maoyuan and Nanjing Ebil demonstrate perfect on-time delivery records, indicating strong production planning and execution discipline. Nanjing Ebil stands out with sub-2-hour response times and broad customization depth, particularly in structural reinforcement and environmental protection features. Guangzhou Maobang leads in transaction volume with over US$1 million in reported online revenue, reflecting extensive market reach and repeat client engagement. Jiangsu-based Nova and Xinzhongya offer competitive per-kilogram pricing, suitable for modular or large-volume deployments, though Xinzhongya’s lower on-time delivery rate (66%) may signal logistical constraints. Buyers seeking rapid prototyping and responsive communication should prioritize suppliers with response times under 3 hours and verified engineering support.

FAQs

How to verify automated storage and retrieval system supplier reliability?

Evaluate suppliers through verifiable performance data including on-time delivery history, response speed, and transaction volume. Request factory walkthrough videos, material certifications, and customer references. Confirm design capability by reviewing sample layouts, load calculations, and integration schematics before placing orders.

What is the typical lead time for ASRS projects?

Standard systems typically require 30–45 days for manufacturing and pre-assembly. Custom-engineered solutions involving mezzanines, elevators, or WMS integration may extend to 60 days. Add 10–20 days for international shipping depending on destination and container availability.

Can ASRS suppliers accommodate bulk or OEM orders?

Yes, most manufacturers support bulk procurement with tiered pricing and private labeling. Minimum order quantities vary—from 1,000 kg for rack components to 5–10 sets for complete systems. OEM services include logo imprinting, color branding, and customized packaging labels.

Do suppliers provide design and installation support?

Leading companies offer full-cycle support including site assessment, 3D layout planning, and assembly drawings. Some provide on-site supervision or partner with local installers. Confirm scope of technical assistance during quotation discussions.

What are common materials and finishes used in ASRS structures?

Primary materials include cold-rolled steel Q235 or Q345, treated with electrophoretic primer and powder-coated finishes for corrosion resistance. Decking options range from steel panels to wire mesh. Surface treatments enhance durability in humid or industrial environments.