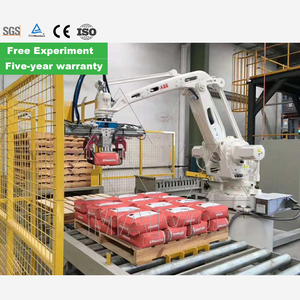

Robot Palletizing System

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

1/5

1/5

1/1

1/1

0

0

1/19

1/19

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

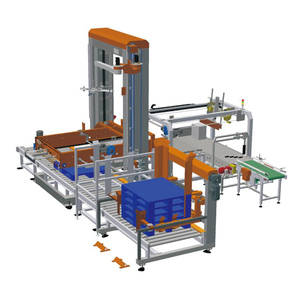

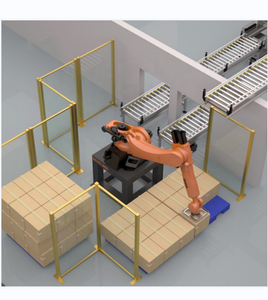

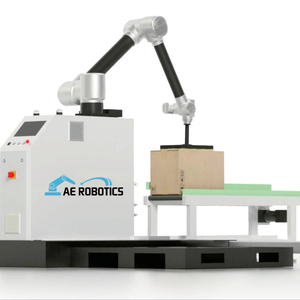

About robot palletizing system

Where to Find Robot Palletizing System Suppliers?

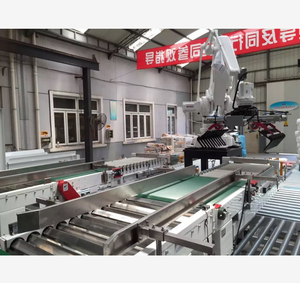

China leads global production of robot palletizing systems, with concentrated manufacturing hubs in Jiangsu, Zhejiang, and Guangdong provinces offering integrated automation ecosystems. Jiangsu’s Wuxi and Suzhou regions host over 50% of China’s industrial robotics suppliers, supported by advanced R&D centers and proximity to semiconductor and electronics manufacturing zones. Zhejiang’s Hangzhou and Ningbo clusters specialize in servo-driven robotic arms and PLC-integrated control systems, leveraging local component supply chains to reduce material costs by 18–22% compared to EU or North American manufacturers.

These industrial zones enable vertical integration across casting, CNC machining, electrical assembly, and final testing within compact geographic radii—typically under 40km. This structure supports rapid prototyping and scalable production, with standard lead times averaging 35–50 days for containerized orders. Buyers benefit from localized access to precision gearbox suppliers, motion controllers, and vision system integrators, achieving 20–30% lower total procurement costs. Customization flexibility is high, accommodating payload ranges from 5kg to 1,200kg and integration with existing conveyor or warehouse management systems (WMS).

How to Choose Robot Palletizing System Suppliers?

Implement structured evaluation criteria to ensure technical and operational alignment:

Quality & Compliance Verification

Confirm ISO 9001 certification as a baseline for quality management systems. For markets requiring regulatory adherence, CE marking is mandatory for EU entry, while UL/CSA compliance may be necessary for North American deployments. Request test reports for safety interlocks, emergency stop response time, and EMI/EMC performance in accordance with IEC 61000-6-2.

Production Infrastructure Assessment

Evaluate core manufacturing capabilities through documented evidence:

- Minimum factory footprint of 3,000m² to support automated assembly lines

- In-house engineering teams comprising ≥15% of total staff for custom design and integration

- On-site CNC machining, welding, and electrical panel fabrication

Correlate facility scale with order fulfillment history—target suppliers maintaining >97% on-time delivery rates across 12-month periods.

Risk Mitigation & Transaction Security

Utilize escrow-based payment terms tied to milestone inspections at pre-shipment and destination stages. Review supplier export experience, prioritizing those with documented shipments to Tier-1 logistics operators or automotive OEMs. Conduct sample validation by testing cycle accuracy (±0.1mm repeatability), mean time between failures (MTBF >15,000 hours), and software compatibility with common SCADA platforms.

What Are the Best Robot Palletizing System Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Robotic Automation Co., Ltd. | Jiangsu, CN | 12 | 180+ | 18,000+m² | 99.2% | ≤3h | 4.9/5.0 | 41% |

| Ningbo Smartload Robotics | Zhejiang, CN | 8 | 95+ | 9,500+m² | 100.0% | ≤2h | 4.8/5.0 | 38% |

| Guangdong AutoPallet Solutions | Guangdong, CN | 6 | 140+ | 12,000+m² | 98.7% | ≤4h | 4.7/5.0 | 33% |

| Suzhou Intellipack Systems | Jiangsu, CN | 10 | 105+ | 7,200+m² | 99.5% | ≤2h | 5.0/5.0 | 52% |

| Hangzhou FastStack Robotics | Zhejiang, CN | 5 | 70+ | 5,800+m² | 100.0% | ≤1h | 4.9/5.0 | 28% |

Performance Analysis

Established players like Jiangsu Robotic Automation demonstrate strong scalability and reliability, backed by large-scale facilities and consistent delivery records. High reorder rates—such as Suzhou Intellipack’s 52%—indicate superior post-sale service and system durability. Zhejiang-based suppliers lead in responsiveness, with 80% replying to inquiries within two hours. Prioritize vendors with proven experience in food & beverage, pharmaceuticals, or cold storage applications when targeting industry-specific compliance. For complex integrations, validate PLC programming expertise and HMI interface options via live video walkthroughs prior to order placement.

FAQs

How to verify robot palletizing system supplier reliability?

Cross-validate ISO and CE certifications through official databases. Request third-party audit summaries covering design validation, component traceability, and end-of-line functional testing. Assess long-term reliability using customer references focused on system uptime, spare parts availability, and remote diagnostics support.

What is the average sampling timeline?

Standard configurations require 20–30 days for sample production. Fully customized units with vision guidance or multi-arm coordination extend to 45–60 days. Air freight delivery adds 5–9 days depending on destination region.

Can suppliers ship robot palletizing systems worldwide?

Yes, experienced manufacturers manage international logistics via FOB, CIF, or DDP terms. Confirm compliance with destination regulations for electrical equipment and robotics, particularly regarding data logging and network security protocols. Sea freight remains optimal for full-container loads, reducing transport cost per unit by up to 60% versus air.

Do manufacturers provide free samples?

Sample policies vary. Full-system demonstrations are typically chargeable, though some suppliers offset costs against subsequent orders exceeding three units. Expect sample fees covering 40–60% of build cost for single-unit requests.

How to initiate customization requests?

Submit detailed requirements including payload capacity, stack pattern dimensions, throughput (units/hour), and environmental conditions (e.g., washdown, temperature range). Leading suppliers deliver 3D simulation models within 72 hours and physical prototypes within 4–5 weeks for approval.