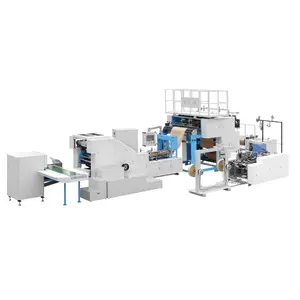

Paper Bag Fully Automatic Machine

CN

CN

Top sponsor listing

Top sponsor listing

About paper bag fully automatic machine

Where to Find Paper Bag Fully Automatic Machine Suppliers?

China remains the global epicenter for manufacturing fully automatic paper bag machines, with key industrial hubs concentrated in Zhejiang, Wenzhou, and Henan provinces. These regions host vertically integrated supply chains encompassing precision machining, servo motor integration, and packaging automation systems. Zhejiang and Wenzhou specialize in high-speed bag-making equipment, leveraging decades of experience in packaging machinery to achieve production efficiencies 20–30% above global averages. Henan’s machinery sector benefits from proximity to raw material suppliers and robust logistics networks, enabling rapid deployment of heavy industrial equipment.

The clustering effect allows suppliers to maintain tight control over component sourcing, assembly, and testing—reducing lead times for standard models to 30–45 days. Buyers gain access to mature ecosystems where R&D, fabrication, and export logistics are co-located within 50km radii. This infrastructure supports both large-volume orders and customized configurations, with many manufacturers offering modular machine designs adaptable to kraft paper, laminated stocks, and water-based adhesive applications.

How to Choose Paper Bag Fully Automatic Machine Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international safety and quality standards. CE marking is essential for European market compliance, while ISO 9001 certification indicates a structured quality management system. Request documentation on electrical control systems (e.g., PLC brands like Siemens or Mitsubishi), servo drive integration, and safety interlock mechanisms. Machines processing food-grade bags should comply with FDA or equivalent material contact regulations.

Production Capability Assessment

Evaluate core manufacturing competencies through verifiable metrics:

- Minimum factory area exceeding 3,000m² to support dedicated assembly lines

- In-house engineering teams capable of customizing bag formats (V-bottom, flat-bottom, side-gusseted)

- Integration of ultrasonic sealing, rotary die-cutting, and automatic stacking systems

Cross-reference claimed capabilities with actual product listings and on-time delivery performance (target ≥90%).

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services to ensure funds are released only after inspection and commissioning. Prioritize suppliers with transparent revenue reporting and reorder rates above 15%, indicating customer retention and satisfaction. Pre-shipment inspections by third-party agencies (e.g., SGS or TÜV) should validate machine functionality against agreed specifications before shipment clearance.

What Are the Best Paper Bag Fully Automatic Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Sample Price Range (USD) |

|---|---|---|---|---|---|---|

| Zhejiang Allwell Intelligent Technology Co., Ltd. | Bag Making Machines (226), Rotogravure Printers (340) | 100% | ≤3h | - | - | Not listed |

| Henan Honglun Machinery Equipment Co., Ltd. | Paper Product Making Machinery (86), Food Processing (155) | 100% | ≤1h | <15% | US $10,000+ | $15,600–24,600 |

| Ruian Xinda Packing Machinery Co., Ltd. | Bag Making Machines (282), Flexographic Printers (90) | 100% | ≤4h | <15% | US $230,000+ | $10,000–135,000 |

| Shenzhen Hanbeter Technology Co., Ltd. | Grain & Meat Processing Machines (1696+) | 90% | ≤1h | 17% | US $140,000+ | $12,520–15,000 |

| Wenzhou Tianyue Machinery Co., Ltd. | Customization Focus: Servo Motor, Color, Size | 100% | ≤3h | 83% | US $500,000+ | $7,000–80,000 |

Performance Analysis

Wenzhou Tianyue stands out with an exceptionally high reorder rate (83%) and competitive entry-level pricing at $7,000 per unit, suggesting strong post-sale reliability and cost efficiency. Zhejiang Allwell and Ruian Xinda demonstrate specialization in bag-making technology, backed by extensive product portfolios and 100% on-time delivery records. Henan Honglun offers fast response times (≤1h) but limited customization visibility, while Shenzhen Hanbeter provides lower-cost options despite a broader focus on food processing machinery. Suppliers with higher online revenues (e.g., Wenzhou Tianyue at US $500,000+) typically have established export processes and multilingual support infrastructure.

FAQs

What certifications should paper bag machine suppliers have?

Essential certifications include CE for EU market access and ISO 9001 for quality assurance. For buyers in North America, UL-listed electrical components are recommended. Confirm that control panels meet IP54 protection standards and emergency stop systems comply with ISO 13850.

What is the typical MOQ and lead time?

Most suppliers set a minimum order quantity of 1 set, facilitating pilot procurement. Standard lead times range from 30 to 45 days after deposit confirmation. Customized models with integrated printing or specialized feeding systems may require 60–75 days for completion.

Can these machines handle different paper types and sizes?

Yes, fully automatic machines typically support grammages from 60gsm to 180gsm kraft, art, or recycled paper. Customizable parameters include bag width (100–600mm), height (150–500mm), and bottom depth. Advanced models feature quick-change tooling for format switching within 30 minutes.

Do suppliers offer installation and training support?

Many suppliers provide remote commissioning via video guidance. On-site technician dispatch is available at additional cost, typically covering machine setup, operator training, and initial run validation. Ensure service terms are defined in the contract prior to shipment.

How to assess machine durability and uptime?

Request MTBF (Mean Time Between Failures) data and review build materials—machines using hardened steel gears and linear guides outperform aluminum counterparts. Benchmark production speed claims (e.g., 200–400 bags/minute) against real-world customer references. Ask for test videos under continuous operation conditions.