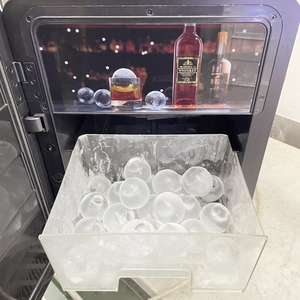

Perfect Ice Sphere Maker

CN

CN

About perfect ice sphere maker

Where to Find Perfect Ice Sphere Maker Suppliers?

China remains the dominant hub for manufacturing ice sphere makers, with key production clusters in Guangdong Province driving innovation and scalability. Shenzhen and Dongguan serve as central nodes in this ecosystem, hosting vertically integrated facilities specializing in food-grade silicone, BPA-free plastics, and precision mold engineering. These regions benefit from mature supply chains for raw materials such as platinum-cured silicone and polycarbonate, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian producers.

The industrial concentration supports rapid prototyping and high-volume output, with many suppliers operating automated injection molding lines capable of producing over 100,000 units monthly. Proximity to Shenzhen Port streamlines export logistics, reducing shipping lead times for global buyers. The region’s specialization in consumer kitchen tools and bar accessories ensures access to skilled labor in product design, ergonomic testing, and packaging customization—critical for premium ice sphere maker brands targeting specialty retail or e-commerce markets.

How to Choose Perfect Ice Sphere Maker Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation protocols focused on material safety, production consistency, and transaction reliability.

Material & Safety Compliance

Verify that suppliers use food-grade silicone (FDA 21 CFR 177.2600 compliant) or BPA-free thermoplastics. Request documentation for RoHS and LFGB certifications, especially for EU and North American markets. Confirm that molds are designed to produce crystal-clear ice spheres without air bubbles, a key quality differentiator for premium beverage applications.

Production Capability Assessment

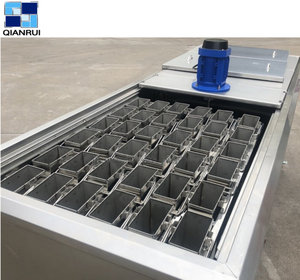

Evaluate the following operational benchmarks:

- Minimum facility size of 2,000m² with dedicated clean-room molding zones

- In-house tooling and mold design teams to support custom cavity configurations (e.g., 4–8 cavity molds)

- Monthly production capacity exceeding 50,000 units for scalable order fulfillment

Cross-reference on-time delivery rates (target ≥97%) and response times (≤3 hours) to assess operational responsiveness.

Customization & Branding Support

Leading suppliers offer Pantone color matching, private labeling, custom packaging inserts, and logo embossing. Confirm availability of 3D renderings and physical samples within 7–10 days. Prioritize partners with experience in retail-ready packaging and barcode integration for direct-to-consumer or wholesale distribution.

What Are the Best Perfect Ice Sphere Maker Suppliers?

| Company Name | Location | Verified Supplier Type | Main Materials | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Shenzhen, CN | Custom Manufacturer | Silicone, BPA-Free Plastic | 97% | ≤3h | 21% | US $220,000+ | Color, shape, mold, packaging, label, logo, graphic |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Shenzhen, CN | Custom Manufacturer | BPA-Free Plastic, Polycarbonate | 93% | ≤3h | <15% | US $250,000+ | Tooling, color, mold, packaging, logo, graphic |

| Whalfly Tek Co., Ltd. | Shenzhen, CN | - | Plastic, Electronic Components | 100% | ≤1h | <15% | US $9,000+ | Limited (focused on electric models) |

| Dongguan Refine Silicone Products Co., Ltd. | Dongguan, CN | - | Food-Grade Silicone | 100% | ≤4h | 40% | US $20,000+ | Size, color, logo, packaging |

| Shenzhen Hafly Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | Silicone, Soft Rubber | 98% | ≤3h | 30% | US $120,000+ | Color, material, size, logo, packaging, graphic |

Performance Analysis

Dongguan Refine Silicone Products stands out with a 40% reorder rate and full on-time delivery record, indicating strong customer satisfaction in material quality and consistency. Shenzhen-based manufacturers dominate in customization depth, particularly in mold design and retail packaging. Whalfly Tek specializes in electric ice ball makers, offering faster response times (≤1h), though with lower transaction volume. Suppliers with "Custom Manufacturer" verification demonstrate broader tooling capabilities, essential for branded or patented designs. For high-volume contracts, prioritize suppliers with >97% on-time performance and documented QC processes.

FAQs

How to verify ice sphere maker supplier reliability?

Cross-check material certifications (FDA, RoHS) and request sample test reports for freeze-thaw durability (minimum 500 cycles without cracking). Analyze supplier transaction history, focusing on dispute resolution speed and sample accuracy. Conduct virtual factory audits to confirm in-house mold-making and quality control stations.

What is the typical sampling timeline?

Standard silicone mold samples take 5–7 days for production and 3–5 days for international shipping. Custom tooling extends lead time to 12–18 days. Electric models may require up to 25 days due to electronic component sourcing.

Can suppliers handle global shipping?

Yes, most suppliers manage FOB Shenzhen or CIF destination shipments. Confirm Incoterms, customs documentation, and compliance with import regulations for kitchenware in target markets. Air freight is recommended for initial trial orders under 500 kg.

Do suppliers provide free samples?

Sample policies vary. Many waive fees for orders exceeding 1,000 units. For smaller quantities, expect to pay 50–100% of unit cost, refundable upon order confirmation. Custom molds typically incur non-refundable tooling charges ranging from $150–$500.

How to initiate customization requests?

Submit detailed specifications including cavity count (4–8 preferred), sphere diameter (50–75mm standard), material type, color codes (Pantone), logo placement, and packaging format. Reputable suppliers provide digital proofs within 48 hours and functional prototypes within 10–14 days.