Perfect Sphere Ice Maker

CN

CN

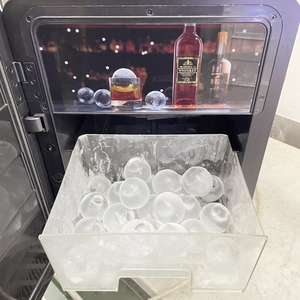

About perfect sphere ice maker

Where to Find Perfect Sphere Ice Maker Suppliers?

China remains the global epicenter for perfect sphere ice maker production, with key manufacturing clusters concentrated in Guangdong and Shenzhen. These regions host vertically integrated supply chains specializing in food-grade silicone molding, injection tooling, and compact electric appliance assembly. Shenzhen-based suppliers dominate mold design innovation, leveraging proximity to polymer R&D centers, while Guangzhou facilities focus on commercial-scale electric ice ball machines with full CE/ETL compliance.

The industrial ecosystem enables rapid prototyping and scalable production—many factories operate dual lines for manual silicone molds and automated electric units. This integration reduces component sourcing lead times by 25–40% compared to decentralized models. Buyers benefit from localized access to raw material suppliers (platinum-cure silicone, BPA-free ABS), precision CNC machining for mold cavities, and certified packaging solutions compliant with EU and FDA standards. Average production lead times range from 15–30 days for standard orders, with MOQs as low as 2 pieces for consumer-grade molds and 10–100 units for electronic models.

How to Choose Perfect Sphere Ice Maker Suppliers?

Procurement decisions should be guided by technical verification, production transparency, and transactional safeguards:

Material & Safety Compliance

Confirm that all contact materials meet food safety standards: platinum-cured silicone (FDA 21 CFR 177.2600) for molds and BPA-free thermoplastics for rigid components. For electric models, demand CE, ETL, or RoHS certification documentation. Verify test reports for electrical insulation, thermal stability, and water resistance (IPX7 minimum for internal circuits).

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum 1,000m² dedicated production area for injection molding and assembly

- In-house mold design team with CAD/CAM and 3D printing prototyping capability

- Monthly output capacity exceeding 50,000 units for high-volume scalability

Cross-reference online revenue metrics and reorder rates (>20% indicates repeat buyer confidence) to assess market performance.

Customization & Branding Flexibility

Leading suppliers offer full private labeling—including Pantone color matching, custom packaging inserts, molded-in logos, and barcode integration. Confirm digital proofing timelines (typically 48 hours) and minimum order thresholds for customization (as low as 100 sets for branded kits). Ensure graphic design support is included for sleeve and label artwork.

What Are the Best Perfect Sphere Ice Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Shenzhen, CN | Silicone ice molds, packaging systems | US $230,000+ | 97% | ≤4h | 20% | 12–100 sets | $0.55–12.50 |

| Shenzhen Mebol Hardware Co., Ltd. | Shenzhen, CN | Baking tools, fruit prep, ice trays | US $80+ | 100% | ≤2h | 100% | 3,000 pieces | $0.60–4.00 |

| Whalfly Tek Co., Ltd. | Guangdong, CN | Electric ice makers, vacuum appliances | US $9,000+ | 100% | ≤1h | <15% | 1–100 pieces | $135.99–159.99 |

| Dongguan Refine Silicone Products Co., Ltd. | Dongguan, CN | Silicone baking & ice tools | US $20,000+ | 100% | ≤4h | 40% | 2–1,000 pieces | $0.85–3.96 |

| Guangzhou Chashimi Kitchen Equipment Co., Ltd. | Guangzhou, CN | Commercial sphere ice machines | US $160,000+ | 94% | ≤5h | <15% | 10–200 pieces | $125–358 |

Performance Analysis

Shenzhen Benhaida leads in low-MOQ flexibility and export-ready packaging customization, ideal for DTC brands requiring small-batch, branded kits. Shenzhen Mebol demonstrates exceptional reliability with a 100% reorder rate and sub-2-hour response time, though its 3,000-piece MOQ suits established distributors. Dongguan Refine offers the lowest entry barrier (MOQ of 2 pieces) and strong repeat business (40% reorder rate), indicating product-market fit. Whalfly Tek specializes in premium electric models with single-unit ordering, critical for retailers testing new categories. Guangzhou Chashimi targets commercial clients with CE/ETL-certified countertop units, but slightly lower on-time delivery (94%) warrants closer logistics coordination. Prioritize suppliers with documented quality control processes and third-party lab testing when sourcing for regulated markets.

FAQs

How to verify material safety for ice maker products?

Request test reports for FDA, LFGB, or SGS certification covering food contact materials. For silicone molds, confirm platinum curing (not peroxide-based) to prevent odor transfer. Audit supplier QC protocols via video inspection of raw material intake and batch testing logs.

What is the typical sampling timeline?

Standard silicone molds require 7–10 days for sample production. Electric models with touchscreen interfaces take 15–20 days due to PCB programming and safety testing. Air shipping adds 5–7 days globally. Many suppliers credit sample fees against bulk orders exceeding 500 units.

Can suppliers accommodate private label branding?

Yes, most leading suppliers offer full OEM/ODM services including custom colors (Pantone matching), molded-in logos, branded packaging, and instruction inserts. Minimum thresholds vary—100 sets for basic labeling, 1,000+ for full graphic redesigns.

Are electric sphere ice makers compliant with international standards?

Select models explicitly labeled with CE, ETL, or RoHS marks. Verify compliance through official certificate numbers traceable to issuing bodies like TÜV or Intertek. Request electrical schematics and fuse rating details to ensure compatibility with destination-market voltage and safety codes.

How to negotiate favorable terms with manufacturers?

Leverage volume commitments (e.g., 5,000+ units annually) for MOQ reductions and payment term extensions. Use competitive quotes from multiple suppliers to benchmark pricing. Secure payment via escrow until product conformity is verified upon arrival. Insist on pre-shipment inspections (AQL Level II) for orders above 1,000 units.