The Perfect Ice Cube Maker

Top sponsor listing

Top sponsor listing

About the perfect ice cube maker

Where to Find the Perfect Ice Cube Maker Suppliers?

China remains the global epicenter for ice cube maker manufacturing, with key production clusters in Guangdong and Jiangsu provinces driving innovation and cost efficiency. Guangdong's Pearl River Delta region hosts a dense network of suppliers specializing in both consumer-grade silicone trays and commercial electric ice machines, supported by mature supply chains for food-grade polymers and refrigeration components. Jiangsu’s Nantong and Suzhou zones focus on industrial-scale ice equipment, leveraging proximity to steel and compressor manufacturers to achieve 15–25% lower material costs compared to offshore producers.

These industrial ecosystems enable vertical integration across molding, assembly, and testing phases, reducing lead times for standard orders to 20–35 days. Suppliers benefit from localized access to injection molding facilities, NSF-certified material labs, and logistics hubs capable of handling LCL or FCL shipments. Buyers gain flexibility in MOQs—from 100 units for niche molds to full container loads for automated ice systems—alongside robust customization options in capacity, shape, and compliance standards.

How to Choose the Perfect Ice Cube Maker Supplier?

Procurement decisions should be guided by three core evaluation criteria:

Product Compliance & Material Safety

Verify that suppliers use food-grade silicone (for trays) or stainless steel (for machines) compliant with FDA, LFGB, or RoHS standards. For commercial ice makers, NSF/CE certification is essential for regulatory approval in North America and Europe. Request test reports for BPA-free composition and thermal stability (-40°C to 230°C for silicone).

Production and Customization Capability

Assess technical infrastructure through the following indicators:

- In-house mold design and 3D prototyping for custom shapes (sphere, square, giant cube)

- Private labeling, Pantone color matching, and packaging design services

- Minimum order flexibility: ≤500 pieces for molded products; ≥1 set for machinery

Cross-reference supplier claims with actual product listings and transaction metrics such as reorder rate (>20% indicates customer retention) and on-time delivery performance (target ≥97%).

Transaction Reliability & Support

Prioritize suppliers with documented quality management systems and responsive communication (response time ≤6 hours). Use secure payment mechanisms like escrow where possible, especially for high-value machinery. Pre-shipment inspections are recommended for bulk orders, particularly for refrigeration units requiring voltage compatibility checks (110V vs. 220V).

What Are the Best the Perfect Ice Cube Maker Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|

| Dongguan Lucky Goldjyx Company Limited | Cake Tools (43), Baking & Pastry Tools (35), Ice Cream Tools (25) | Color, shape, lid, packaging, label, material, size, logo, mold design, 3D drawings | 88% | 22% | ≤6h | US $410,000+ | Varies by product type |

| Guangzhou Huli Catering Equipment Co., Ltd. | Ice Makers (133), Sealing Machines (7), Water Heaters (7) | Not specified | 100% | 25% | ≤2h | US $8,000+ | 1 piece/set |

| Nantong Wuding Technology Co., Ltd. | Ice Machines (382), Commercial Ice Cream Machines (173) | Not specified | 100% | <15% | ≤4h | US $60,000+ | 1 set |

| Dongguan Qiaotou Kingsage Silicone Rubber Factory | Ice Cream Tools (332), Cake Tools (129) | Limited data available | 100% | - | ≤20h | US $300+ | 100–500 pieces |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Silicone trays, cavity molds, food-grade plastic goods | Color, shape, Pantone, mold, packaging, private label, barcode, graphic design | 97% | 22% | ≤3h | US $230,000+ | 50–100 units |

Performance Analysis

Guangzhou Huli and Nantong Wuding lead in reliability with 100% on-time delivery and low response times, making them ideal for urgent commercial ice machine procurement. Shenzhen Benhaida and Dongguan Lucky Goldjyx offer extensive customization for branded silicone trays, supported by strong reorder rates and advanced mold design capabilities. While Dongguan Qiaotou Kingsage provides competitive pricing and low MOQs, its slower response time may impact project timelines. Buyers seeking large-volume production should prioritize suppliers with proven export experience and revenue exceeding US $50,000 annually.

FAQs

How to verify the quality of an ice cube maker supplier?

Request documentation for material compliance (e.g., FDA, LFGB), review factory audit videos if available, and analyze transaction history including on-time delivery rate and customer feedback. Third-party inspection services can validate product samples before mass production.

What is the typical MOQ for silicone ice trays and commercial ice machines?

Silicone tray MOQs range from 50 to 500 pieces depending on complexity and customization. Commercial electric ice makers typically require a minimum order of 1 set, though some suppliers allow single-unit trials.

Can suppliers customize ice cube shapes and branding?

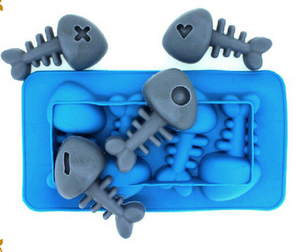

Yes, multiple suppliers offer mold development for non-standard shapes (e.g., spheres, diamonds, logos). Full branding support—including custom colors, labels, packaging, and private labeling—is available from specialized silicone manufacturers.

What are common lead times for ice cube maker orders?

Standard silicone tray orders take 15–25 days after sample approval. Custom molds add 7–14 days for development. Commercial ice machines require 25–40 days for production, depending on cooling capacity and certification requirements.

Do suppliers provide samples before bulk ordering?

Most suppliers offer pre-production samples. Sample fees vary: $0.60–$2.00 for basic trays; $200–$1,000 for commercial ice machines. Fees may be waived upon confirmation of large orders.