Plastic Button Maker

About plastic button maker

Where to Find Plastic Button Maker Suppliers?

China remains the central hub for plastic button maker manufacturing, with key production clusters in Zhejiang, Guangdong, and Fujian provinces. These regions host vertically integrated supply chains that streamline raw material sourcing, mold fabrication, and final assembly. Yiwu and Ningbo in Zhejiang specialize in small-format manual pressing equipment used for DIY and promotional badge production, while Dongguan and Foshan in Guangdong focus on semi-automatic and pneumatic systems for higher-volume operations.

The industrial ecosystem supports rapid prototyping and low-to-mid volume production runs, with localized access to ABS, PVC, and polycarbonate sheet suppliers reducing material lead times by 15–25%. Many factories operate multi-shift schedules, enabling monthly output capacities ranging from 500 to 5,000 units depending on automation level. Buyers benefit from compact supplier networks—component vendors, tooling workshops, and packaging specialists are typically within a 30km radius—supporting faster iteration and reduced logistics overhead.

How to Choose Plastic Button Maker Suppliers?

Effective supplier selection requires verification across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm compatibility with standard button formats (e.g., 50mm, 58mm, 75mm diameters or rectangular variants). Machines should accommodate plastic domes, mylar covers, and metal backs without requiring third-party adapters. While formal certifications such as CE or ISO 9001 are not universally listed, prioritize suppliers who provide detailed engineering schematics, material safety data sheets (MSDS), and compliance with RoHS directives for EU-bound shipments.

Production Capability Assessment

Evaluate infrastructure indicators including:

- Minimum factory area of 1,000m² for dedicated machinery lines

- In-house tooling and mold-making capabilities for custom die sets

- Presence of post-processing stations (e.g., trimming, magnet attachment, quality inspection)

Cross-reference online revenue metrics and listing volume—suppliers with over 100 product listings in button-making equipment indicate established specialization.

Order Flexibility & Transaction Security

Most suppliers offer MOQs starting at 1 piece, facilitating sample testing and pilot runs. However, unit pricing varies significantly—from $13 for basic handheld models to $2,999 for semi-automatic pneumatic presses. Use platform-backed payment protection where available. Prioritize suppliers with response times under 2 hours and on-time delivery rates exceeding 95% to minimize procurement risk.

What Are the Best Plastic Button Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Yiwu Chuxin Technology Co., Ltd | Zhejiang, CN | Button Making Machines (106) | US $10,000+ | 88% | ≤1h | 16% | Not specified |

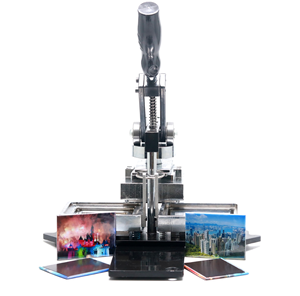

| Dongguan Dinglian Machinery Co., Ltd. | Guangdong, CN | Heat Press Machine (254), Button Making Machines (101) | US $220,000+ | 100% | ≤2h | <15% | Not specified |

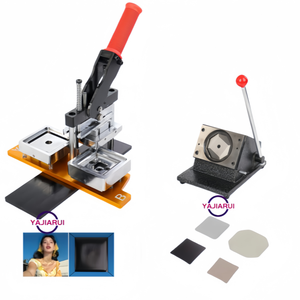

| Foshan Yajiarui Machinery Co., Ltd. | Guangdong, CN | Filling Machines (284), Button Making Machines (82+) | US $130,000+ | 100% | ≤1h | <15% | Not specified |

| Ningbo Bs Printing Machinery Equipment Co., Ltd. | Zhejiang, CN | Post-Press Equipment (211), Button Making Machines (18) | US $50,000+ | 100% | ≤2h | 35% | Color, material, size, logo, packaging, label, graphic |

| Guangzhou Image Art Digital Technology Co., Ltd. | Guangdong, CN | Manual Badge & Button Makers (5+ active listings) | US $110,000+ | 89% | ≤4h | <15% | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Dongguan Dinglian and Foshan Yajiarui demonstrate strong operational reliability with 100% on-time delivery and high online revenue, indicating consistent export experience. Although their reorder rates are below 15%, this may reflect niche positioning in industrial-grade equipment rather than consumer-facing products. Notably, Ningbo Bs Printing Machinery stands out with a 35% reorder rate—the highest among peers—suggesting strong customer satisfaction, possibly due to its broad customization options. Yiwu Chuxin leads in product variety specific to button makers (106 listings), making it suitable for buyers seeking standardized manual models. Guangzhou Image Art offers granular customization but slower response times, which may affect urgent procurement cycles.

FAQs

What is the typical MOQ for plastic button makers?

Most suppliers list a minimum order quantity of 1 piece, allowing for single-unit sampling. Bulk discounts apply at 10+ units, particularly for automated or pneumatic models.

How long does production and shipping take?

Lead time for standard machines ranges from 7–15 days after payment confirmation. Air freight delivery to North America or Europe takes 5–10 days; sea freight requires 25–35 days. Customized units may extend production by 7–14 days.

Can suppliers customize button maker designs?

Yes, select manufacturers like Ningbo Bs Printing Machinery and Guangzhou Image Art support customization of color, material, size, and branding elements. Technical modifications (e.g., press force, die shape) require direct engineering consultation and may involve NRE fees.

Are spare parts and technical support available?

Limited after-sales documentation is publicly available. Buyers should request part diagrams, replacement die availability, and maintenance guidelines prior to purchase. Some suppliers include basic toolkits and instructional videos with shipment.

What payment methods do suppliers accept?

Commonly accepted methods include T/T (bank transfer), Alibaba Trade Assurance, and PayPal for samples. For orders above $10,000, letters of credit (L/C) may be negotiable with high-volume suppliers.