Pointer Producer

1/11

1/11

0

0

1/3

1/3

0

0

1/18

1/18

1/3

1/3

1/3

1/3

1/25

1/25

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

About pointer producer

Where to Find Pointer Producer Suppliers?

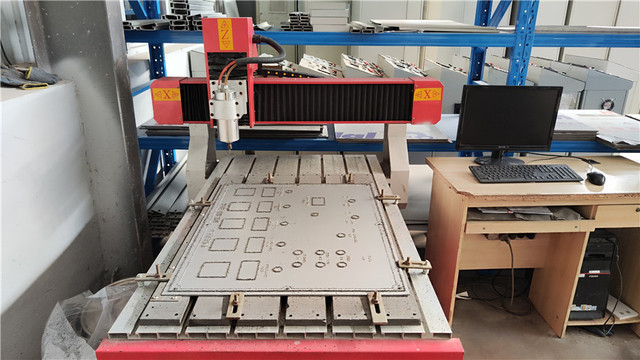

China remains the central hub for industrial pointer production, with key manufacturing clusters in Henan, Shandong, and Jiangsu provinces driving efficiency and specialization. Zhengzhou in Henan Province hosts integrated machinery ecosystems that support full-cycle production of automated systems, including precision pointers used in measurement, control, and instrumentation equipment. These regions benefit from concentrated supply chains—ranging from CNC machining centers to electronic component suppliers—enabling rapid prototyping and scalable manufacturing.

The industrial clusters offer logistical and cost advantages, with established export infrastructure supporting global distribution. Suppliers leverage localized access to raw materials such as aluminum alloys, stainless steel, and engineering plastics, reducing material procurement lead times by up to 30%. Average production cycle times range from 30–60 days depending on customization complexity, with bulk orders benefiting from vertical integration across casting, machining, surface treatment, and assembly stages. Buyers gain flexibility in both standard and OEM configurations, supported by widespread adoption of modular design principles.

How to Choose Pointer Producer Suppliers?

Selecting a reliable supplier requires systematic evaluation of technical capability, quality assurance, and transaction reliability:

Production Infrastructure Verification

Assess whether suppliers operate dedicated production lines capable of maintaining consistency in dimensional accuracy and surface finish. Prioritize manufacturers with documented in-house capabilities in CNC machining, laser marking, and robotic assembly. Minimum facility size should exceed 2,000m² for high-volume contracts, with evidence of process automation to ensure repeatability. Confirm integration of calibration protocols for pointer components requiring ±0.01mm tolerance.

Quality Management Standards

Require ISO 9001 certification as a baseline for quality system compliance. For applications in regulated industries (e.g., aerospace, medical devices), verify adherence to ISO 13485 or AS9100 where applicable. Request test reports for material composition, corrosion resistance (e.g., salt spray testing for coated pointers), and durability under operational stress. CE marking may be necessary for European market entry, particularly if the pointer is part of a larger CE-certified system.

Customization & Technical Support

Evaluate suppliers’ ability to accommodate custom specifications:

- Material options: aluminum, brass, stainless steel, polycarbonate, or composite polymers

- Surface treatments: anodizing, powder coating, plating, or UV-resistant printing

- Dimensional adaptability: length, thickness, pivot mechanism, balance weight integration

- Graphic labeling: laser engraving, silk screening, or digital printing for scale alignment

Confirm availability of CAD modeling support and prototype validation within 10–14 days. Suppliers offering collaborative design reviews and 3D renderings demonstrate higher engineering engagement.

Transaction Reliability Indicators

Analyze performance metrics such as on-time delivery rate (target ≥98%), reorder frequency, and response time. Suppliers with response times under 2 hours typically maintain dedicated international sales teams. Use verifiable transaction volume indicators—such as annual online revenue exceeding US $50,000—as proxies for export experience. Prefer partners offering secure payment terms and third-party inspection options prior to shipment.

What Are the Best Pointer Producer Suppliers?

| Company Name | Location | Main Products | Production Type | Price Range (Unit or Set) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|---|

| Zhengzhou Yugong Construction Machinery Co., Ltd. | Henan, CN | Construction machinery production lines | Multispecialty Supplier | $7,800–8,900/set | 1 set | 100% | ≤2h | 40% | US $700,000+ |

| Jiaozuo Shuangyi Filter Co., Ltd. | Henan, CN | Filter components, precision parts | Custom Manufacturer | $1.80–2.80/piece | 20 pieces | 100% | ≤2h | 35% | US $60,000+ |

| Shandong Xulida Machinery Co., Ltd. | Shandong, CN | Wood panel, gluing, coating machinery | Own Production Line | $18,000–22,000/set | 1 set | 100% | ≤1h | <15% | US $10,000+ |

| Nanjing Energy Intelligent Co., Ltd. | Jiangsu, CN | Safety monitoring systems, metal processing lines | OEM/ODM Capable | $300,000/set | 1 set | 100% | ≤9h | - | - |

| Wenzhou Vince Machinery Science Co., Ltd. | Zhejiang, CN | Dairy, beverage, food processing lines | Turnkey System Provider | $96,000–158,000/set | 1 set | 100% | ≤4h | <15% | US $5,000+ |

Performance Analysis

Zhengzhou Yugong and Jiaozuo Shuangyi stand out for strong reorder rates (40% and 35%, respectively) and fast response times, indicating robust customer satisfaction and service responsiveness. Jiaozuo Shuangyi offers the lowest MOQ and unit pricing, making it suitable for small-scale or trial orders involving precision pointer components. Nanjing Energy Intelligent targets high-end automation systems with large capital investments, suggesting suitability for integrated pointer-based monitoring solutions. Shandong Xulida demonstrates the fastest average response time (≤1h), reflecting efficient communication protocols despite lower reorder frequency. Wenzhou Vince provides mid-range pricing for complete processing lines where pointers are embedded in control panels or gauges.

FAQs

How to verify pointer producer reliability?

Cross-validate ISO certifications and request factory audit reports or video tours confirming in-house machining and quality inspection stations. Examine transaction history for consistent on-time delivery and review customer feedback focusing on product accuracy and post-sale support.

What is the typical minimum order quantity?

MOQ varies significantly: component-level suppliers like Jiaozuo Shuangyi accept 20-piece orders, while full production line integrators require single-set purchases. Negotiate tiered pricing for volumes exceeding 100 units or equivalent system installations.

Can suppliers customize pointer design and materials?

Yes, most suppliers support customization of color, material (metal/plastic), dimensions, labeling, and graphic elements. Confirm feasibility through technical drawings and sample prototypes before mass production.

Do manufacturers provide samples?

Sample availability depends on complexity. Simple pointer parts may be provided at partial cost, especially with confirmed purchase intent. For integrated system pointers, expect sampling lead times of 10–20 days and associated tooling fees for custom molds or fixtures.

What are standard lead times for production and shipping?

Manufacturing lead times range from 30 days for standard components to 60 days for fully customized or automated systems. Sea freight adds 20–35 days for international delivery, while air shipping reduces transit to 5–10 days at higher cost.