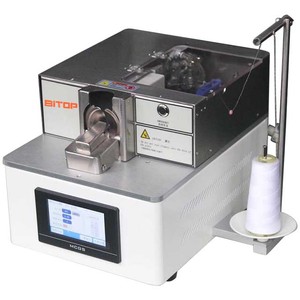

Polyester Button Making Machine

1/29

1/29

1/15

1/15

1/6

1/6

1/12

1/12

1/9

1/9

1/10

1/10

About polyester button making machine

Where to Find Polyester Button Making Machine Suppliers?

China remains the central hub for polyester button making machine production, with key manufacturing clusters in Hebei, Henan, and Zhejiang provinces. These regions host vertically integrated facilities capable of producing both manual and automated machinery for button assembly, lamination, and fastening processes. Hebei-based suppliers leverage proximity to raw material sources for polyester components, reducing input costs by 10–15%. Meanwhile, Zhejiang’s Hangzhou and Yancheng zones specialize in precision engineering for semi-automatic and fully automatic systems, integrating servo controls and pneumatic pressing technologies.

The industrial ecosystems support scalable output, with leading factories maintaining monthly production capacities exceeding 500 units across product lines. Concentrated supplier networks enable rapid component sourcing—particularly for dies, molds, and pressing tools—ensuring lead times of 20–35 days for standard configurations. Buyers benefit from localized supply chains that allow cost efficiencies (20–30% below Western OEMs) and flexibility in customization for size, force pressure, and material compatibility (including polyester films and laminates).

How to Choose Polyester Button Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

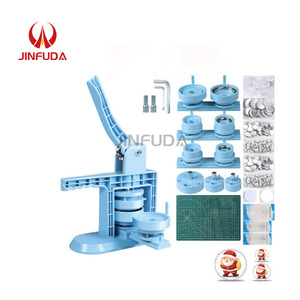

Confirm machine specifications align with intended use: manual models typically suit small-batch operations (e.g., DIY badges), while pneumatic or automatic systems are necessary for industrial throughput. Demand documentation on processing parameters—such as pressing force (measured in kN), cycle time, and compatible button diameters (ranging from 25mm to 75mm). For polyester applications, ensure tooling resists thermal deformation during lamination cycles.

Production Infrastructure Assessment

Evaluate core indicators of manufacturing maturity:

- Minimum factory area of 1,000m² for consistent quality control

- In-house R&D or engineering teams focused on mechanical design and automation

- Integrated testing protocols for durability and safety compliance

Cross-reference declared capabilities with on-time delivery performance (target ≥98%) and reorder rates above 15% as proxies for reliability and customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services until post-delivery inspection is completed. Prioritize suppliers with transparent response times (ideally ≤3 hours) and verifiable online transaction histories. Request functional prototypes or pre-shipment videos for complex configurations. Insist on third-party quality inspections if ordering more than five units to validate consistency in build quality.

What Are the Best Polyester Button Making Machine Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Hengshui Mengshang Trading Co., Ltd. | Hebei, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤2h | Online revenue US $220,000+ | 21% |

| Zhengzhou Jieyuan Machinery Manufacturing Co., Ltd | Henan, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤3h | Online revenue US $10,000+ | <15% |

| Hangzhou Qike Technology Co., Ltd. | Zhejiang, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤2h | Online revenue US $420,000+ | 19% |

| Talent (Tianjin) Electronics Co., Ltd. | Tianjin, CN | Data Unavailable | Data Unavailable | Data Unavailable | 96.0% | ≤10h | Online revenue US $330,000+ | <15% |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Jiangsu, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100.0% | ≤3h | Online revenue US $120,000+ | 17% |

Performance Analysis

Hengshui Mengshang and Hangzhou Qike demonstrate strong market retention, supported by high reorder rates (21% and 19%) and sub-3-hour response times. Hangzhou Qike offers advanced semi-automatic and laminating models suited for polyester composite buttons, reflecting its specialization within apparel machinery ecosystems. Zhengzhou Jieyuan focuses on high-tonnage automatic systems priced above $1,600, indicating orientation toward industrial clients requiring continuous operation. Talent (Tianjin), despite slightly lower on-time delivery (96%), provides extensive customization options—including shape, color, and magnet integration—making it suitable for niche branding applications. Yancheng Stik Pro balances affordability and responsiveness, offering entry-level models starting at $60 per set ideal for startups or promotional product vendors.

FAQs

How to verify polyester button making machine supplier reliability?

Validate supplier credibility through documented transaction volume, response consistency, and delivery track record. Request evidence of ISO 9001 certification where available. Analyze product listings for technical specificity—generic descriptions may indicate trading companies rather than manufacturers. Prefer suppliers who provide detailed schematics, operation manuals, or video demonstrations upon request.

What is the average lead time for sample machines?

Standard sample units ship within 7–15 days after order confirmation. Customized models with specific die sizes or voltage requirements (e.g., 110V vs. 220V) require 20–30 days for configuration and testing. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate OEM/ODM requests?

Yes, multiple suppliers listed offer full customization including logo branding, packaging design, and control panel interfaces. Talent (Tianjin) explicitly lists machine cutter, shape, and graphic customization as available services. Minimum order quantities for branded units typically start at 5 sets.

Do suppliers provide free samples?

Free samples are uncommon due to equipment size and cost. Most suppliers charge full price for initial units but may credit the amount upon placement of a bulk order (typically 10+ sets). Sample pricing generally reflects production cost plus shipping.

What are typical MOQ and pricing ranges?

Manual and small-scale machines start at $29/set with no minimum order beyond one unit. Automated systems have MOQs of 1–5 sets and price points ranging from $1,350 to $1,980 per unit. Larger orders attract incremental discounts averaging 5–12%, negotiable based on payment terms and annual volume commitments.