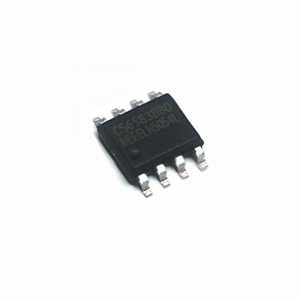

Precision Constant Current Source Ic

About precision constant current source ic

Where to Find Precision Constant Current Source IC Suppliers?

China remains the central hub for semiconductor component manufacturing, with Shenzhen emerging as a dominant cluster for integrated circuit (IC) sourcing. The city hosts a dense ecosystem of electronics suppliers specializing in precision analog ICs, including constant current source solutions. This concentration enables streamlined access to design support, testing facilities, and logistics networks optimized for global component distribution.

Shenzhen-based suppliers benefit from proximity to wafer fabrication services, packaging subcontractors, and quality control laboratories, reducing production lead times by 20–30% compared to non-specialized regions. The local supply chain supports rapid prototyping and low-volume sampling, with many firms offering turnkey solutions from die-level design to finished tape-and-reel packaging. Buyers gain flexibility in order scale, with standard lead times averaging 15–25 days for stocked items and 4–6 weeks for custom configurations.

How to Choose Precision Constant Current Source IC Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Competence & Product Range

Verify supplier expertise in analog IC applications such as LED drivers, sensor biasing, and precision instrumentation. Leading suppliers offer parts compliant with AEC-Q100 (for automotive), RoHS, and REACH standards. Confirm availability of supporting documentation—detailed datasheets, application notes, thermal models, and SPICE simulation files—are provided for all listed components.

Production and Quality Assurance

Assess internal capabilities through verifiable indicators:

- On-time delivery performance exceeding 97%

- Response time under 3 hours for technical inquiries

- Evidence of systematic quality management (e.g., ISO 9001 alignment)

- Use of automated optical inspection (AOI) and burn-in testing for batch validation

Prioritize suppliers with dedicated R&D teams focused on power management IC development, particularly those offering high-precision references (±0.5% or better) and low temperature drift characteristics.

Procurement Flexibility and Risk Mitigation

Evaluate minimum order quantities (MOQs), pricing tiers, and sample policies. Many suppliers accommodate MOQs as low as 1 piece for evaluation, though volume pricing typically begins at 50–100 units. Utilize secure transaction methods where available, ensuring payment protection until product verification is complete. Request sample batches to validate parametric accuracy, load regulation, and thermal stability before scaling procurement.

What Are the Best Precision Constant Current Source IC Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Wanxinwei Technology Co., Ltd. | LED drivers, current sensing ICs, operational amplifiers | US $850,000+ | 100.0% | 26% | ≤5h | 1 piece | $0.01–1.00 | Yes |

| Shenzhen Jeking Electronic Corp. | Step-down converters, constant voltage/current controllers | US $320,000+ | 100.0% | 39% | ≤3h | 2 pieces | $0.10–0.60 | Yes |

| Shenzhen Pengying Electronics Co., Ltd. | Precision linear ICs, LED step-down controllers | US $50,000+ | 100.0% | 26% | ≤1h | 1 piece | $0.16–0.95 | No |

| Shenzhen E-Solution Technology Limited | High-precision PSR, sensor interface ICs | US $50,000+ | 100.0% | 15% | ≤4h | 10 pieces | $0.10–2.00 | No |

| Shenzhen By Technology Co., Ltd. | PMICs, current monitors, reference ICs (e.g., LM4040, INA203) | US $30,000+ | 100.0% | <15% | ≤2h | 50 pieces | $0.48–17.19 | No |

Performance Analysis

Shenzhen Wanxinwei leads in accessibility with sub-dollar pricing and single-unit MOQs, making it ideal for prototype development and small-scale integration. Jeking demonstrates strong customer retention (39% reorder rate), suggesting consistent product reliability and responsive service. Pengying excels in responsiveness (≤1h average reply time), a critical factor for time-sensitive design cycles. By Technology focuses on higher-end PMIC-grade components, reflected in elevated price points and larger MOQs, aligning with industrial and automotive-tier requirements. While none explicitly list ISO certification, all maintain 100% on-time delivery records, indicating robust order fulfillment systems.

FAQs

How to verify precision constant current source IC supplier reliability?

Cross-check technical specifications against published datasheets from original manufacturers. Request evidence of incoming material inspection reports and final electrical testing procedures. Analyze reorder rates and response times as proxies for service consistency. For mission-critical applications, require sample validation using precision source-measure units to confirm current accuracy and thermal drift performance.

What is the typical sampling timeline for ICs?

Stocked components are generally shipped within 3–7 business days after payment. Custom programming or labeling extends lead time to 10–15 days. Air freight adds 5–10 days for international delivery. Plan for up to 4 weeks if new part qualification or lot testing is required.

Can suppliers provide RoHS-compliant or automotive-grade variants?

Many suppliers list compliance as part of product descriptions. However, explicit confirmation and documentation (e.g., IPC/JEDEC test reports, SGS certificates) should be requested prior to procurement. Automotive-grade suitability often requires AEC-Q100 qualification, which must be verified per part number.

Do suppliers support private labeling or packaging customization?

Selected suppliers, including Shenzhen Jeking and Wanxinwei, offer packaging, label, and logo customization for orders above 1,000 units. Lead time may increase by 5–7 days. Minimum fees may apply for small-batch branding requests.

How to negotiate better pricing for volume orders?

Leverage tiered pricing structures by aggregating demand across projects. Suppliers typically offer 10–25% discounts when moving from 100 to 1,000+ unit tiers. Establish long-term agreements with forecast sharing to secure allocation priority during supply constraints. Always confirm whether quoted prices include tape-and-reel, cut-tape, or tube packaging.