Printed Circuit Board Design And Fabrication

Top sponsor listing

Top sponsor listing

1/3

1/3

1/29

1/29

1/26

1/26

1/26

1/26

1/60

1/60

1/20

1/20

1/61

1/61

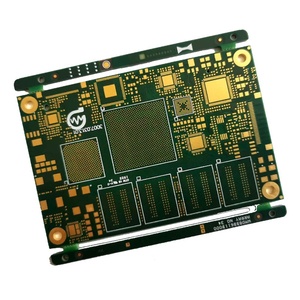

About printed circuit board design and fabrication

Where to Find Printed Circuit Board Design and Fabrication Suppliers?

China remains the global epicenter for printed circuit board (PCB) design and fabrication, with Shenzhen and Dongguan serving as primary manufacturing hubs. These regions host a dense network of vertically integrated suppliers offering end-to-end services—from schematic capture and layout engineering to bare board fabrication, component sourcing, and full PCBA assembly. Shenzhen alone accounts for over 60% of China’s electronics contract manufacturers, supported by mature supply chains for FR4, ENIG, HASL, and flexible substrate materials.

The concentration of technical talent, component distributors, and rapid prototyping facilities within these clusters enables lead times as short as 5–7 days for multilayer prototypes and 12–18 days for production batches. Localized sourcing reduces material costs by 15–25% compared to Western equivalents, while proximity between design houses, fabrication plants, and testing labs ensures tighter quality control and faster iteration cycles. Buyers benefit from scalable solutions ranging from one-off R&D boards to high-volume automated assembly lines capable of processing 10,000+ units monthly.

How to Choose Printed Circuit Board Design and Fabrication Suppliers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Technical Capability Validation

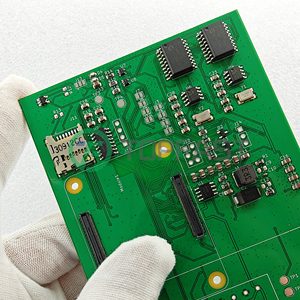

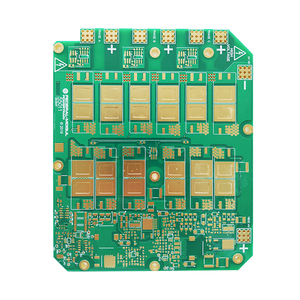

Confirm expertise in required stack-up configurations (1–12 layer standard, up to 32 layers for advanced applications), surface finishes (HASL, ENIG, OSP), and impedance control. Suppliers should support Gerber file validation, DFM checks, and reverse engineering services. Prioritize those with in-house design engineers and experience in complex integrations such as Wi-Fi mesh modules, Raspberry Pi compatibility, or RF/wireless signal integrity.

Production & Quality Assurance Infrastructure

Assess operational scale and process controls through the following indicators:

- On-time delivery rate ≥95%

- Reorder rate exceeding 30% as a proxy for customer satisfaction

- Response time under 4 hours for technical inquiries

- Documented adherence to IPC-A-600/6012 standards and RoHS compliance

- In-house capabilities in wave soldering, SMT, BOM fulfillment, and functional testing

Cross-reference service claims with verifiable performance metrics such as online revenue volume and order history where available.

Transaction Security and IP Protection

Require signed confidentiality agreements prior to sharing sensitive designs or firmware. Utilize secure transaction channels that support milestone-based payments and post-delivery inspection rights. Ensure suppliers can provide full traceability of components, including original source documentation and counterfeit mitigation protocols. Prototyping partners should offer proofing samples with detailed test reports before scaling to mass production.

What Are the Best Printed Circuit Board Design and Fabrication Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| King Field Electronic Co., Ltd. | Shenzhen, CN | Multilayer PCB, FPC, Rigid PCB, PCBA | Design, assembly, copying, logo finish, material selection, Gerber support | 95% | 32% | ≤2h | US $190,000+ | 100 pcs |

| Shenzhen Mrcss Electronic Co., Ltd. | Shenzhen, CN | PCB, PCBA, Component Assembly | Design, component integration, assembly | 91% | <15% | ≤4h | US $490,000+ | 100 pcs |

| DONGGUAN TOPWELL TECHNOLOGY CO.,LTD | Dongguan, CN | Custom PCB, Power Electronics, Enclosure Design | Full electronic design, structural modeling, firmware, RF modules | 100% | <15% | ≤3h | US $680,000+ | 1 set |

| Topfast Technology Co.,Ltd. | Shenzhen, CN | Prototype PCB, PCBA, Multilayer Boards | Prototyping, replication, hotswap, RGB integration, packaging | 97% | 45% | ≤4h | US $610,000+ | 1 piece |

| Shenzhen Fulltronics Corporation Limited | Shenzhen, CN | Multilayer PCB, Double-sided PCB, FPC, PCBA | Limited customization noted; strong in standard multilayer builds | 93% | 18% | ≤4h | US $150,000+ | 1 piece |

Performance Analysis

Top performers like DONGGUAN TOPWELL and Topfast Technology demonstrate robust technical breadth, supporting full-cycle development from concept to finished product. DONGGUAN TOPWELL stands out with a perfect 100% on-time delivery record and low MOQs starting at one set, ideal for early-stage prototyping. Topfast Technology leads in customer retention with a 45% reorder rate, reflecting consistent output quality and responsive service. King Field offers balanced capabilities with extensive customization options across solder resist colors, layer counts, and finish types. While Shenzhen Mrcss reports high transaction volume, its sub-15% reorder rate suggests potential gaps in long-term client satisfaction. Buyers requiring complex board architectures or enclosure-integrated designs should prioritize suppliers with documented experience in thermal management, EMI shielding, and multi-board system integration.

FAQs

How to verify PCB supplier technical competence?

Request sample Gerber files, DFM reports, and material declarations. Verify experience with your specific requirements—such as impedance-controlled layouts, blind vias, or high-frequency routing. Conduct virtual audits to observe engineering workflows and testing procedures.

What is the typical lead time for custom PCBs?

Standard 2-layer boards take 5–7 days for prototypes and 10–14 days for production runs. Multilayer (6–12 layer) boards require 10–15 days for sampling and 18–25 days for volume orders, depending on complexity and finishing processes.

Do suppliers support small-batch or prototype orders?

Yes, most leading suppliers accept MOQs as low as 1 piece or 1 set. Topfast Technology and DONGGUAN TOPWELL explicitly cater to R&D teams with single-unit prototyping and fast turnaround services.

Are RoHS and REACH compliance standards enforced?

Reputable suppliers adhere to RoHS and REACH directives by default, using lead-free materials and maintaining restricted substance inventories. Request compliance certificates and batch-specific test data for regulated markets.

Can suppliers assist with component sourcing and BOM fulfillment?

Yes, full-turnkey providers manage complete BOM procurement, including active components, passives, connectors, and specialized ICs. Confirm availability tracking, substitution policies, and anti-counterfeit measures during due diligence.