Prototype Production

Top sponsor listing

Top sponsor listing

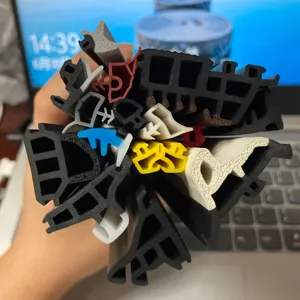

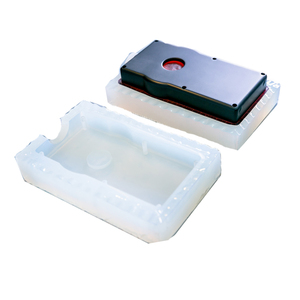

About prototype production

Where to Find Prototype Production Suppliers?

China remains the global hub for prototype production, with key manufacturing clusters in Guangdong, Jiangsu, and Zhejiang provinces driving innovation and efficiency. Shenzhen and Guangzhou specialize in rapid prototyping technologies such as 3D printing, CNC machining, and vacuum casting, supported by dense networks of material suppliers and design engineers. These regions offer vertically integrated ecosystems where product development cycles are compressed through co-located tooling, testing, and low-volume assembly services.

The industrial infrastructure enables fast turnaround times—typically 5–10 days for standard prototypes—with scalability for batch production up to 10,000 units monthly. Localized supply chains reduce material lead times by 30–40%, while proximity to ports like Shekou and Shanghai ensures efficient global shipping. Buyers benefit from flexible MOQs (often starting at 1 piece), competitive labor costs, and access to advanced processing techniques including SLA, SLS, and multi-axis CNC milling.

How to Choose Prototype Production Suppliers?

Selecting a reliable partner requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm expertise in required prototyping methods: CNC machining (metal/plastic), 3D printing (SLA/SLS/FFF), vacuum casting, or sheet metal fabrication. Review equipment inventory, including laser sintering machines or high-precision mills, and validate compatibility with engineering-grade materials such as ABS, PA, PC, aluminum, or stainless steel. Demand sample test reports or digital proof-of-concept renderings before full engagement.

Production Infrastructure Assessment

Evaluate supplier capacity using these benchmarks:

- On-site production lines with documented process control systems

- Dedicated quality inspection stations (e.g., CMM, optical comparators)

- In-house mold-making or CAD/CAM design teams

Cross-reference facility size and response time metrics with on-time delivery performance (target ≥97%) to assess operational reliability.

Quality & Transaction Assurance

Prioritize suppliers demonstrating consistent quality management—look for ISO 9001 compliance or equivalent frameworks. Analyze reorder rates (above 40% indicates strong customer satisfaction) and response times (≤4 hours suggests dedicated support). Utilize secure payment mechanisms and request post-delivery validation protocols, especially for functional or cosmetic prototypes intended for user testing or investor presentations.

What Are the Best Prototype Production Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Verified Type |

|---|---|---|---|---|---|---|---|

| Zhangjiagang Friend Machinery Co., Ltd. | Plastic Extruders, Granulators, Pipe Making Machinery | Nozzle diameter, material thickness, width, capacity | 100% | 25% | ≤11h | US $690,000+ | Custom Manufacturer |

| Guangzhou Seal Laser Rapid Prototype Co., Ltd. | 3D Printing, SLA, Vacuum Casting, RIM | Color, material (PA), mold type, packaging, logo, 3D drawings | 100% | 50% | ≤4h | US $10,000+ | Custom Manufacturer |

| Shenzhen Kaier Wo Prototyping Technology Co., Ltd. | Vacuum Casting, CNC Machining, Die Casting | Anodization, resin material, mold design, rapid prototyping | 100% | 42% | ≤2h | US $650,000+ | Custom Manufacturer |

| Suzhou Whale Stone 3d Technology Co., Ltd. | Machining Services, SLA, Aluminum Prototypes | Material type, part geometry, weight-based pricing | 64% | 33% | ≤3h | US $20,000+ | - |

| Torch Mold Limited | CNC Machining, Plastic/Metal Prototypes | Color, surface finish, packaging, assembly, drawing specs | 97% | 26% | ≤2h | US $130,000+ | Multispecialty Supplier |

Performance Analysis

Suppliers like Shenzhen Kaier Wo and Guangzhou Seal Laser demonstrate high service responsiveness (≤2h and ≤4h response times, respectively) and perfect on-time delivery records, indicating robust internal coordination. Guangzhou Seal Laser stands out with a 50% reorder rate—suggesting strong client retention driven by customization depth and quality consistency. In contrast, Suzhou Whale Stone shows lower on-time performance (64%), which may reflect capacity constraints despite offering gram-based pricing ideal for small, lightweight prototypes.

Established players such as Zhangjiagang Friend Machinery and Torch Mold Limited report higher online revenue volumes, correlating with broader machinery integration capabilities. For buyers requiring end-to-end development—from concept modeling to pilot runs—suppliers with in-house mold design, material sourcing, and finishing options provide greater control over final output fidelity.

FAQs

How to verify prototype supplier reliability?

Request evidence of quality control processes, including inspection checklists, equipment calibration logs, and sample traceability records. Validate technical claims through video audits of production floors and review digital portfolios of past projects. High reorder rates and sub-4-hour response times serve as proxy indicators of operational stability.

What is the typical lead time for custom prototypes?

Standard lead times range from 3 to 7 days for 3D-printed or CNC-machined parts, depending on complexity and finishing requirements. Vacuum casting or urethane molding typically takes 5–10 days, including master model creation and demolding. Expedited services may reduce timelines by 40% with premium fees.

Do suppliers support low-volume production after prototyping?

Yes, many manufacturers offer seamless transition to small-batch production (MOQ 1–100 units). Suppliers with integrated tooling and assembly lines can maintain design integrity while scaling output, minimizing requalification efforts for pre-launch validation stages.

Are material certifications available for regulated industries?

Reputable suppliers provide material datasheets and RoHS compliance documentation upon request. For medical or aerospace applications, confirm availability of UL-listed resins, FDA-approved polymers, or MIL-STD testing alignment prior to order placement.

How are design files protected during prototyping?

Establish NDAs before file submission and confirm data handling policies. Leading suppliers implement encrypted file transfer systems, restrict internal access, and delete client designs post-project unless storage agreements are in place.