Rapid Prototype Molding

Top sponsor listing

Top sponsor listing

CN

CN

About rapid prototype molding

Where to Find Rapid Prototype Molding Suppliers?

China remains the global hub for rapid prototype molding, with key manufacturing clusters concentrated in Guangdong Province—particularly Shenzhen and Dongguan. These regions host vertically integrated supply chains combining precision tooling, CNC machining, 3D printing, and injection molding under one ecosystem. Proximity to material suppliers, electronics manufacturers, and logistics networks enables agile development cycles critical for prototyping.

The industrial infrastructure supports both low-volume sampling and scalable production transitions. Facilities typically integrate digital design validation, vacuum casting, SLA/SLS 3D printing, and soft-tool injection molding, allowing clients to iterate designs within 3–7 days. Localized sourcing of engineering resins (ABS, nylon, TPU, POM) and metals (aluminum 7075, stainless steel) reduces input costs by 18–25% compared to Western counterparts. Buyers benefit from short lead times (5–15 days for prototypes), flexible MOQs starting at 1 piece, and seamless transition paths to mass production.

How to Choose Rapid Prototype Molding Suppliers?

Selecting reliable partners requires a structured evaluation across technical, operational, and transactional dimensions:

Design & Engineering Capabilities

Confirm access to multidisciplinary design support including mechanical engineering, PCB integration, firmware development, and structural simulation. Top-tier suppliers offer full ID/MD design services, 3D rendering, and functional prototyping. Verify expertise in biodegradable materials, overmolding, insert molding, and multi-material assembly when required.

Production Infrastructure

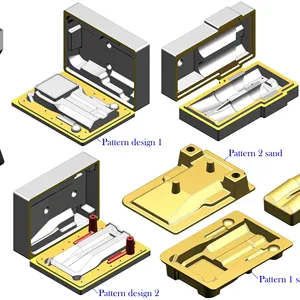

Assess core competencies through these indicators:

- In-house capabilities spanning CNC machining, 5-axis milling, sheet metal fabrication, and vacuum casting

- Use of industrial-grade 3D printing (MJF, SLS, SLA) for high-detail prototypes

- Dedicated mold-making workshops with steel/hardened tooling options

Cross-reference service breadth with online revenue data and reorder rates to gauge market validation.

Quality & Responsiveness Metrics

Prioritize suppliers demonstrating 100% on-time delivery and response times under 4 hours. Reorder rates above 50% indicate strong client retention and satisfaction. While formal certifications (ISO 9001, RoHS) are not explicitly listed in available data, consistent performance metrics suggest robust internal quality management systems. Request QC documentation, material traceability reports, and test samples before scaling orders.

What Are the Best Rapid Prototype Molding Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

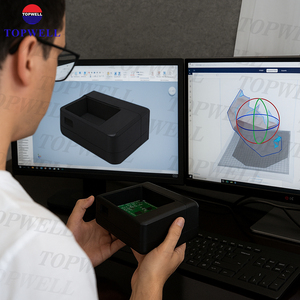

| Shenzhen Topwell Innovations Co., Ltd. | Shenzhen, CN | Moulds, PCBA, Machining Services, Smart Watches | Full product development: ID design, electronics, firmware, packaging, magnets, resin, TPU, die-cast | 100% | ≤4h | 50% | US $700,000+ |

| Dongguan Yyi Technology Co., Ltd. | Dongguan, CN | Machining Services | Material selection (ABS, nylon, PP), vacuum casting, 3D printing, auto parts molding | 100% | ≤3h | 58% | US $40,000+ |

| TONGSHENG TONGCHUANG INTELLIGENT EQUIPMENT COMPANY LIMITED | Not specified | Machining Services, Moulds, Sheet Metal, Springs | Stainless steel CNC, aluminum 7075, large-scale MJF 3D print | 100% | ≤10h | - | US $90+ |

| Guangzhou Mr.mould Electrical Appliance Co., Ltd. | Guangzhou, CN | Other Plastic Products, Moulds, Medical Plastic | Injection molding (ABS, POM, PA), metal/plastic CNC prototypes | 100% | ≤4h | <15% | US $90,000+ |

| Yuyao City Yunpeng Plastic Mould Co., Ltd. | Yuyao, CN | Plastic Moulds, 3D Printing (SLA/SLS) | Color, material, size, logo, packaging, label customization | 100% | ≤3h | <15% | - |

Performance Analysis

Shenzhen Topwell stands out with comprehensive end-to-end product development capabilities, serving clients requiring full-system integration from concept to assembled units. Its high reorder rate (50%) and substantial online revenue reflect proven scalability and customer trust. Dongguan Yyi Technology excels in responsiveness (≤3h) and repeat business (58% reorder rate), indicating strong service consistency despite lower revenue volume.

Yuyao City Yunpeng and Guangzhou Mr.mould focus on core molding and 3D printing services with moderate customization depth. Though both maintain perfect on-time delivery records, their sub-15% reorder rates suggest limited post-prototype engagement or niche positioning. TONGSHENG TONGCHUANG offers broad machining and spring component capabilities but lacks verifiable transaction history, warranting further due diligence.

FAQs

What is the typical lead time for rapid prototype molds?

Simple silicone molds for vacuum casting take 3–5 days. Hard steel injection molds require 7–14 days depending on complexity. 3D-printed prototypes can be delivered in 2–4 days with express processing.

What are common MOQs in rapid prototype molding?

MOQs range from 1 piece for 3D printed or cast prototypes to 100–500 units for soft-tool injection runs. Some suppliers offer zero-MOQ sampling at higher per-unit costs.

Can suppliers handle electronic integration in prototypes?

Yes, select suppliers like Shenzhen Topwell provide full PCB design, firmware programming, and electromechanical assembly, enabling fully functional prototypes for smart devices and IoT products.

How are materials selected for prototype fidelity?

Suppliers match material properties (flexibility, heat resistance, tensile strength) to final production specs. Common choices include ABS for rigidity, TPU for elasticity, and nylon for wear resistance. Biodegradable options are available upon request.

What should buyers verify before placing an order?

Request design review feedback, sample photos, material datasheets, and QC checklists. Conduct video audits of production lines if transitioning to volume manufacturing. Use milestone-based payment terms to mitigate risk during initial collaborations.