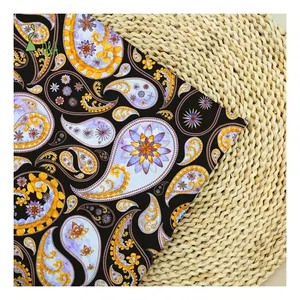

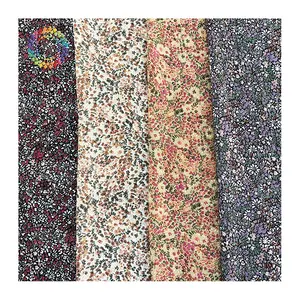

Repeat Pattern

CN

CN

0

0

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/26

1/26

1/3

1/3

0

0

1/3

1/3

0

0

0

0

0

0

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/2

1/2

1/2

1/2

About repeat pattern

Where to Find Repeat Pattern Suppliers?

No verified suppliers for repeat pattern manufacturing were identified in the current dataset. As a result, no concentrated production clusters or established industrial ecosystems can be confirmed for this product category at this time. Typically, repeat pattern production—used in textiles, wallpapers, and digital design applications—relies on regions with strong capabilities in digital printing, textile engineering, or graphic design services. In mature markets, such capabilities are often found in Guangdong, Zhejiang, and Jiangsu provinces in China, where integrated supply chains support high-volume surface pattern replication across fabric and material substrates.

In absence of supplier data, buyers should consider that effective repeat pattern sourcing depends on access to advanced digital design tools, color-matching systems, and scalable output infrastructure. Facilities equipped with CAD/CAM software, automated looms, or wide-format printers typically offer higher precision in pattern alignment and repeatability. Lead times for customized designs generally range from 10–25 days depending on complexity, with MOQs varying from 50m² for printed materials to 500 linear meters for woven textiles. Without active supplier presence, cost advantages linked to regional clustering—such as reduced material handling or shared logistics networks—cannot be leveraged.

How to Choose Repeat Pattern Suppliers?

Due to the absence of available suppliers, selection criteria must remain anticipatory. However, based on industry benchmarks for similar design-intensive manufacturing sectors, the following verification protocols are recommended when evaluating future partners:

Technical Compliance

Confirm adherence to international quality standards such as ISO 9001 for design process control. For EU-bound products, verify compliance with REACH and RoHS regulations regarding dye chemicals and substrate materials. Request documentation of colorfastness testing (e.g., ISO 105-B02) and seam alignment accuracy reports, particularly for large-scale installations.

Production Capability Audits

Assess technical infrastructure through documented evidence of:

- Digital design suites supporting AI, EPS, and PSD file formats

- Minimum 8-color rotary screen or digital inkjet printing capacity

- In-house prototyping with physical sample turnaround under 7 days

Validate integration between design software and output machinery to ensure seamless tiling, registration, and scale consistency across batches.

Transaction Safeguards

Implement escrow-based payment terms until design approval and sample validation are completed. Prioritize suppliers offering revision cycles and pixel-perfect alignment guarantees. Where platform transaction histories exist, analyze dispute resolution records related to color deviation, pattern mismatch, or minimum order enforcement.

What Are the Best Repeat Pattern Suppliers?

No supplier data is currently available for repeat pattern manufacturers. The absence of operational entities in the dataset precludes performance benchmarking, facility comparisons, or responsiveness analysis. Consequently, no companies can be listed or evaluated for factory size, delivery reliability, staff expertise, or customer retention metrics.

Performance Analysis

Without active suppliers, market differentiation factors such as reorder rates, response speed, or customization agility cannot be assessed. Buyers should remain cautious of unverified listings claiming high-volume capabilities or rapid turnaround without verifiable audit trails. When suppliers emerge, prioritize those demonstrating integration between creative design workflows and industrial production systems—particularly those offering DPI resolution above 300, tile registration tolerance within ±0.5mm, and scalable roll-to-roll processing.

FAQs

How to verify repeat pattern supplier reliability?

In the absence of supplier data, verification remains contingent on future due diligence. Once candidates emerge, request third-party audit reports covering design workflow management, ink/material sourcing, and batch consistency controls. Evaluate sample outputs against specified repeat type (e.g., half-drop, brick, or seamless). Confirm ownership of original design files and rights clearance for commercial use.

What is the average sampling timeline?

For standard repeat patterns using existing templates, expect 5–7 days for digital proofs and 7–10 days for physical samples. Custom artwork development may extend timelines to 14–21 days, especially when color matching to Pantone or RAL standards is required. Add 5–8 days for international express shipping.

Can suppliers ship repeat pattern products worldwide?

When available, established manufacturers typically support global distribution via air or sea freight. Confirm whether goods are shipped in rolled form or panelized, as this affects packaging dimensions and import classification. Clarify FOB terms and responsibility for customs clearance, particularly for printed textiles subject to anti-dumping duties in certain jurisdictions.

Do manufacturers provide free samples?

Sample policies vary by material and volume commitment. Some suppliers waive costs for small-format swatches (e.g., A4 or 12"x12") if followed by orders exceeding 200 units or 100 linear meters. Larger format or backlit material samples usually incur fees covering material and handling expenses.

How to initiate customization requests?

Submit vector-based artwork (AI, PDF, or SVG) with clearly defined repeat parameters: offset values, symmetry type, and bleed margins. Specify substrate requirements (cotton, polyester, vinyl, etc.), fire ratings (e.g., ASTM E84), and environmental conditions (indoor/outdoor). Reputable suppliers will return proof renders within 48–72 hours and confirm print readiness within one week.