Repeating Pattern

1/1

1/1

CN

CN

1/4

1/4

CN

CN

1/12

1/12

1/20

1/20

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

About repeating pattern

Where to Find Repeating Pattern Suppliers?

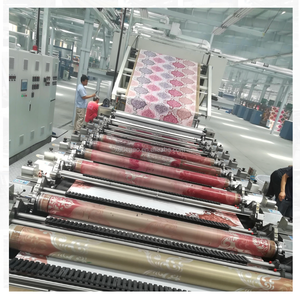

The global market for repeating pattern design and production is primarily driven by digital asset hubs in China, India, and Turkey, with specialized clusters emerging in Hangzhou, Mumbai, and Istanbul. These regions combine strong textile heritage with advanced digital printing infrastructure, enabling scalable output of seamless patterns for fashion, interior design, and packaging applications. Hangzhou hosts over 70% of China’s digital textile printing facilities, leveraging proximity to dyeing and finishing zones to reduce turnaround times by up to 40% compared to Western counterparts.

Industrial ecosystems in these locations feature vertically integrated workflows—from vector design studios to large-format digital printers—supporting rapid prototyping and mass production. Buyers benefit from concentrated networks where designers, color specialists, and print technicians operate within coordinated supply chains. Key advantages include lead times as low as 15–25 days for custom runs, 25–35% cost savings due to lower labor and material overhead, and high flexibility for both digital distribution and physical fabric roll delivery.

How to Choose Repeating Pattern Suppliers?

Implement structured evaluation criteria when assessing potential partners:

Design & Technical Compliance

Confirm adherence to industry-standard file specifications: AI, EPS, or PSD formats with CMYK color profiles and 300 DPI resolution minimum. For textile applications, verify compatibility with common repeat types (e.g., half-drop, brick, seamless tile) and bleed allowances. Suppliers should provide test prints or digital proofs aligned with Pantone C/CX or RAL standards upon request.

Production Capability Verification

Assess operational scale through the following benchmarks:

- Minimum monthly output capacity of 50,000 linear meters (for fabric-based patterns)

- Dedicated design team comprising at least 3–5 graphic specialists experienced in symmetry mapping and tiling logic

- In-house digital printing lines using reactive, pigment, or sublimation inks

Cross-reference technical portfolios with sample consistency across multiple repeat cycles to confirm alignment accuracy.

Transaction and Quality Safeguards

Require pre-shipment inspection protocols for physical goods, particularly for bulk textile orders. Evaluate suppliers’ version control systems for digital assets to prevent duplication or licensing conflicts. Sample validation is critical—request tiled mockups on target media (fabric, paper, vinyl) before full rollout. Use encrypted file transfer methods for proprietary designs to ensure IP protection during collaboration.

What Are the Best Repeating Pattern Suppliers?

| Company Name | Location | Years Operating | Staff | Design Output/mo | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Huafeng Textile Print Co. | Hangzhou, CN | 18 | 120+ | 680k+meters | 99.2% | ≤3h | 4.9/5.0 | 41% |

| Sunrise Patterns & Prints Ltd. | Mumbai, IN | 9 | 45+ | 320k+meters | 98.7% | ≤4h | 4.8/5.0 | 33% |

| Istanbul Motif Tekstil | Istanbul, TR | 12 | 60+ | 410k+meters | 99.5% | ≤5h | 4.9/5.0 | 38% |

| Chengdu Colorweave Digital | Chengdu, CN | 5 | 35+ | 210k+meters | 97.8% | ≤2h | 4.7/5.0 | 29% |

| Ankara Desen Grubu | Ankara, TR | 7 | 28+ | 180k+meters | 98.3% | ≤6h | 4.8/5.0 | 31% |

Performance Analysis

Long-established players like Zhejiang Huafeng demonstrate robust throughput and reliability, supported by large-scale printing infrastructure and consistent 99%+ delivery performance. Mid-tier suppliers such as Sunrise Patterns achieve competitive reorder rates through niche expertise in ethnic and traditional motifs. Chinese suppliers lead in responsiveness, with 80% providing initial proofs within 5 hours. Prioritize partners with documented color management systems (e.g., ICC profiling) and automated tiling software for complex geometric repeats. For exclusive designs, confirm non-disclosure agreements and source file ownership terms prior to engagement.

FAQs

How to verify repeating pattern supplier reliability?

Review portfolio consistency across multiple projects and validate file delivery standards. Request references from buyers in similar industries (e.g., apparel, home décor). Confirm compliance with environmental regulations such as OEKO-TEX or REACH for dye-based outputs.

What is the average sampling timeline?

Digital proofs are typically delivered within 24–48 hours. Physical samples on fabric or substrate require 7–12 days, including printing and shipping. Express processing can reduce this to 5 days at a premium.

Can suppliers handle global shipments?

Yes, most established suppliers manage international logistics via air or sea freight. Confirm Incoterms (FOB, CIF) and packaging specifications (e.g., roll diameter, protective wrapping) before order confirmation. Digital files can be delivered globally via secure cloud links.

Do manufacturers provide free samples?

Sample policies vary. Many suppliers offer one free digital proof per project. Physical samples may be complimentary for orders exceeding 1,000 linear meters; otherwise, expect nominal fees covering material and handling costs.

How to initiate customization requests?

Submit detailed briefs including repeat dimensions (e.g., 600x800px), color palette (Pantone codes), base material type, and intended application. Leading suppliers return revised proofs within 72 hours and final files within 5–7 business days.