Robotic Automation In Manufacturing

CN

CN

About robotic automation in manufacturing

Where to Find Robotic Automation in Manufacturing Suppliers?

China leads global production of robotic automation systems for manufacturing, with concentrated industrial hubs in Guangdong, Shenzhen, and Shandong provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable manufacturing. Guangdong and Shenzhen specialize in high-precision articulated and collaborative robots, leveraging proximity to electronics and semiconductor industries. Shandong focuses on heavy-duty automation solutions, including large-payload robotic arms and integrated welding systems, supported by mature metalworking and CNC machining clusters.

The regional ecosystems enable cost efficiencies through localized component sourcing—reducing material lead times by 20–35% compared to offshore alternatives. Facilities typically integrate design, assembly, and testing under one roof, allowing standard orders to be fulfilled within 30–45 days. Buyers benefit from flexible MOQs (as low as 1 set) and access to modular platforms adaptable for pick-and-place, palletizing, welding, and precision handling applications. Average production cost savings range from 25–40% versus Western suppliers, driven by optimized labor structures and streamlined logistics.

How to Choose Robotic Automation in Manufacturing Suppliers?

Evaluate potential partners using the following criteria to ensure technical reliability and transactional security:

Technical Capabilities and Product Range

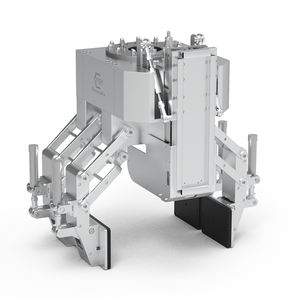

Confirm supplier expertise in relevant robot types: articulated, linear, parallel, or collaborative (cobot) systems. Prioritize companies offering validated performance data such as repeatability (±0.02mm typical), payload capacity (up to 300kg), and axis configurations (4–6 axes standard). Verify compatibility with end-of-arm tooling like grippers and welding heads. Cross-reference product listings with application-specific use cases in electronics, automotive, or packaging sectors.

Quality Assurance and Compliance

While formal certifications (e.g., ISO 9001, CE) are not explicitly stated in available data, assess compliance indirectly via operational metrics. Target suppliers with documented on-time delivery rates ≥97%, response times ≤2 hours, and third-party transaction validation where available. Inquire directly about adherence to IEC 61508 (functional safety) and RoHS standards, particularly for export-bound equipment.

Production Infrastructure and Scalability

Evaluate key indicators of manufacturing maturity:

- Online revenue exceeding US $300,000 annually indicates volume capability

- Dedicated R&D focus evident in customization options (color, size, logo, packaging)

- In-house engineering teams capable of system integration and turnkey solutions

Correlate these factors with reorder rates above 25% to identify reliable, service-oriented suppliers.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk. Request pre-shipment inspection rights and insist on sample testing for critical parameters like cycle time accuracy and thermal stability. For customized systems, require 3D models or simulation files before production begins. Confirm FOB/CIF shipping terms and clarify responsibility for customs clearance and import duties.

What Are the Best Robotic Automation in Manufacturing Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Annual Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Guangdong Borunte Robot Technology Co., Ltd. | Guangdong, CN | Articulated Robots, Collaborative Robots, Welding Arms | $999 – $24,300 | 1 set | 66% | ≤3h | 100% | US $20,000+ |

| Shenzhen Jufeng Jingke Automation Technology Co., Ltd. | Shenzhen, CN | Linear Robots, Actuators, Motion Modules | $65 – $450 | 1 piece | 100% | ≤1h | 25% | US $10,000+ |

| Shenzhen Era Automation Co., Ltd. | Shenzhen, CN | Collaborative Robots, AGVs, Grippers | $360 – $12,900 | 1 set | 100% | ≤2h | <15% | US $350,000+ |

| Shandong UMW Technology Co., Ltd. | Shandong, CN | 6-Axis Articulated Robots, Welding Systems | $3,400 – $25,999 | 1 set | 100% | ≤2h | 29% | US $680,000+ |

| Henan Addis Technology Co., Ltd. | Henan, CN | Palletizing Robots, AGVs, Packaging Lines | $18,800 – $28,500 | 1 set | 100% | ≤2h | <15% | Data Unavailable |

Performance Analysis

Shenzhen-based suppliers demonstrate superior responsiveness, with three achieving average reply times under two hours. Shandong UMW Technology stands out for scale and revenue output (US $680,000+), indicating strong international market penetration and repeat business. Guangdong Borunte exhibits a unique 100% reorder rate despite a lower on-time delivery score, suggesting high customer satisfaction post-delivery. Shenzhen Jufeng Jingke offers the lowest entry price point ($65) for linear modules, making it ideal for budget-sensitive integrations. Henan Addis targets mid-to-high-end automation with fully automatic palletizing systems priced between $18,800 and $28,500, though lack of revenue verification warrants due diligence.

FAQs

How to verify robotic automation supplier reliability?

Request factory audit reports, video walkthroughs of production lines, and references from past buyers. Validate claimed capabilities against listed products and pricing consistency. Use platform-backed transaction systems to monitor fulfillment history and dispute resolution outcomes.

What is the typical lead time for robotic automation systems?

Standard units ship within 20–35 days after order confirmation. Customized robotic cells or integrated production lines may require 45–60 days depending on complexity and component availability.

Do suppliers offer customization for robotic systems?

Yes, multiple suppliers provide tailored solutions in size, color, branding, and functional configuration. Shandong UMW and Shenzhen Era Automation explicitly list customization options for structural and operational parameters, suitable for OEM integration.

Can robotic automation suppliers handle global shipping?

All listed suppliers have international transaction experience. Confirm whether shipping includes export documentation, crating, and insurance. Sea freight is recommended for full-system deployments to minimize transport costs.

Are samples available for robotic automation equipment?

Sample policies vary. Some suppliers offer single-unit purchases at list price, effectively serving as test units. Full-scale prototypes for custom systems may incur development fees but can be credited toward bulk orders.