Robotics Pcb Assembly

CN

CN

CN

CN

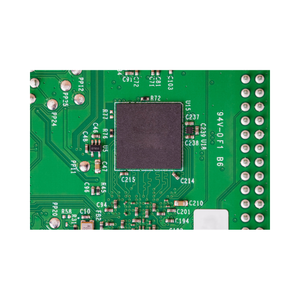

About robotics pcb assembly

Where to Find Robotics PCB Assembly Suppliers?

China remains a central hub for advanced electronics manufacturing, with specialized clusters in Guangdong, Fujian, and Guangxi provinces leading in robotics-focused PCB assembly production. These regions host vertically integrated facilities capable of delivering high-mix, low-to-medium volume orders with rapid turnaround—critical for robotics applications requiring iterative prototyping and customized control systems. Proximity to component distribution centers in Shenzhen reduces material sourcing lead times by 10–15 days compared to offshore alternatives.

The ecosystem supports full-service electronic manufacturing, from SMT and through-hole assembly to firmware programming, box-build integration, and global logistics. Suppliers in this sector commonly offer turnkey solutions, including component procurement, PCB cloning, IC programming, and housing assembly. Buyers benefit from scalable production models: pilot runs as small as 1 piece are feasible, while established suppliers can scale to thousands of units monthly. Average lead times range from 7–21 days depending on complexity, with express services available for urgent prototypes.

How to Choose Robotics PCB Assembly Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Process Compliance

Confirm adherence to IPC-A-610 Class 2 or Class 3 standards for electronics assembly. For robotics applications involving motion control, sensor fusion, or AI processing, verify capabilities in multilayer PCBs (up to 12 layers), high-frequency circuit handling, and precision SMT placement (down to 0201 components). RoHS and ISO 9001 compliance should be documented, especially for export to regulated markets.

Production Capability Assessment

Evaluate the supplier’s infrastructure and service scope:

- In-house SMT lines with automated optical inspection (AOI) and X-ray inspection for BGA packages

- Support for mixed-technology assemblies (SMT + through-hole)

- Firmware/embedded software programming and testing protocols

- Customization options: color, labeling, packaging, logo printing, and housing integration

Cross-reference delivery performance metrics; prioritize suppliers with ≥98% on-time delivery rates and response times under 4 hours.

Procurement & Risk Mitigation

Use milestone-based payment terms with quality holdbacks. Request sample boards before mass production to validate solder joint integrity, component placement accuracy, and functional performance. For complex robotics PCBs involving AI, SLAM, or soft actuation systems, require test reports and, where possible, access to facility walkthrough videos to confirm process control.

What Are the Best Robotics PCB Assembly Suppliers?

| Company Name | Specialization | Min. Order Quantity | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Key Capabilities |

|---|---|---|---|---|---|---|---|---|

| Tecoo Electronics Co., Ltd. | Robotics drive systems, vacuum cleaner PCBs | 10–100 pieces | $2–23.39 | 98% | ≤2h | 35% | Yes | Global component sourcing, clone PCB, IC programming, housing assembly, label & packaging customization |

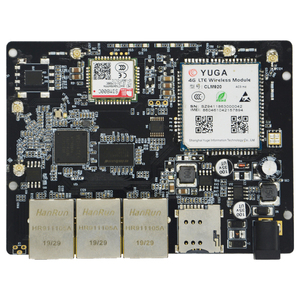

| INTELLISENSE TECHNOLOGY | AI robotics, SLAM, EAP actuators, IoT controls | 99–200 pieces | $99–4,999 | Not specified | ≤4h | Not specified | Limited | Advanced embedded control, custom firmware, AI-driven circuit design, autonomous mobile robot PCBs |

| Liuzhou LUNKO Technology Co., Ltd. | AI-integrated robotics, microwave robotics, OEM vacuum cleaners | 1 piece | $0.20–500 | 100% | ≤5h | Not specified | Yes | Low-MOQ prototyping, color/material/logo customization, flexible packaging, single-piece ordering |

| Fuzhou Zhongwei Electronic Technology Co., Ltd. | Motion sensors, LCD boards, signal conversion modules | 2 sets | $2,000 (set) | 100% | Not specified | Not specified | Yes | Custom multilayer PCBs, single/double-sided assembly, machining integration, motion control electronics |

Performance Analysis

Tecoo Electronics stands out with a verified 98% on-time delivery rate and strong reorder performance (35%), supported by comprehensive customization and global component sourcing. Liuzhou LUNKO offers exceptional flexibility with one-piece minimum orders and competitive pricing down to $0.20/unit, ideal for R&D and prototype phases. INTELLISENSE TECHNOLOGY targets high-end robotics applications with premium-priced boards ($99–$4,999), indicating specialization in AI, SLAM, and soft robotics—suitable for advanced development programs. Fuzhou Zhongwei serves niche industrial clients with high-value custom sets, suggesting focus on engineered-to-order solutions rather than volume production.

FAQs

How to verify robotics PCB assembly supplier reliability?

Check documented compliance with IPC and ISO standards. Request evidence of testing procedures (ICT, functional test, AOI) and review component traceability practices. Analyze response consistency, order fulfillment history, and customer feedback on technical support and defect resolution.

What is the typical MOQ and pricing structure?

MOQs vary widely: from 1 piece (prototyping) to 100+ pieces for cost-optimized runs. Prices range from under $1 for basic designs to over $4,000 for complex AI-enabled boards. Unit costs decrease significantly at volumes above 500 units due to setup amortization.

Can suppliers handle full turnkey assembly?

Yes, many offer end-to-end services including component procurement, PCB fabrication, SMT assembly, programming, testing, and final packaging. Some also provide housing integration and color-box packaging for consumer robotics products.

Do suppliers support PCB cloning and reverse engineering?

Several suppliers, including Tecoo Electronics and Fuzhou Zhongwei, explicitly offer PCB cloning, enabling replication of legacy or competitor boards with updated materials or form factors—useful for maintenance or product redesign.

What are the lead times for samples and bulk orders?

Sample lead times average 7–12 days. Bulk production typically takes 15–21 days after design approval. Express services may reduce timelines by 30–50%, depending on component availability and process complexity.