Robots Used In Factories

Top sponsor listing

Top sponsor listing

1/15

1/15

1/5

1/5

1/3

1/3

1/33

1/33

CN

CN

About robots used in factories

Where to Find Suppliers for Robots Used in Factories?

China remains a central hub for industrial robotics manufacturing, with key supplier clusters concentrated in Zhejiang, Shandong, and Guangdong provinces. These regions host vertically integrated production ecosystems that combine precision engineering, electronics assembly, and automation R&D. Ningbo and Jinan are notable for articulated and collaborative robot production, while Guangdong specializes in service-oriented commercial robots adapted for smart factory environments.

The industrial infrastructure supports rapid prototyping and scalable output, with suppliers typically operating facilities exceeding 5,000m² and maintaining in-house CNC machining, welding, and control system integration capabilities. This localization reduces component lead times and enables cost efficiencies—production costs in these clusters are estimated 20–35% lower than equivalent systems sourced from Western manufacturers. Buyers benefit from short development cycles, with standard units often available within 30–45 days post-order confirmation.

How to Choose Suppliers for Factory Robots?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm whether the supplier offers certified robotic systems compliant with ISO 9001 and CE standards, particularly for deployment in regulated industries. For collaborative robots (cobots), verify compliance with ISO/TS 15066 for human-robot interaction safety. Request documentation on motor performance, payload capacity, repeatability metrics, and controller compatibility.

Production and Customization Capacity

Assess manufacturing depth through the following indicators:

- Facility size and automation level (e.g., use of robotic arms in final assembly)

- In-house design teams capable of modifying arm reach, end-effector interfaces, or programming environments

- Customization options including software integration, labeling, color schemes, and grid layout designs

Cross-reference declared capabilities with product listings showing configurable parameters such as degrees of freedom, speed, and communication protocols (e.g., Modbus, Ethernet/IP).

Supply Chain Reliability and Transaction Security

Prioritize suppliers with verifiable on-time delivery rates above 90% and response times under 3 hours. Analyze reorder rates as an indicator of customer satisfaction—rates exceeding 50% suggest consistent quality and support. Use secure payment mechanisms and require post-delivery inspection windows before final disbursement, especially when procuring used or refurbished units.

What Are the Leading Suppliers of Robots Used in Factories?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

| Ningbo Vichnet Technology Co., Ltd. | Fencing, Cable Trays, Locks, Wiring Ducts | 100% | 62% | ≤3h | US $630,000+ | Yes (color, material, size, logo, packaging, drawing, mesh height) | Custom Manufacturer |

| Jinan Stark Machinery Equipment Co., Ltd. | Conveyors, Collaborative Robots, Articulated Robots | 92% | 33% | ≤1h | US $80,000+ | No explicit mention | - |

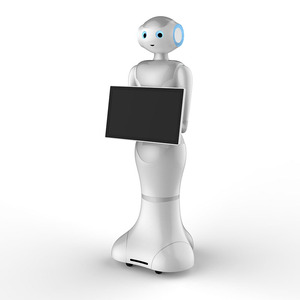

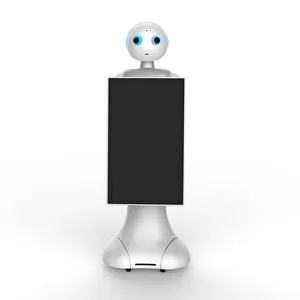

| Guangdong Exhibition Hall Intelligent Equipment Co., Ltd. | Commercial Delivery, Reception, Cleaning Robots | 71% | 50% | ≤1h | US $20,000+ | Yes (intelligent, customizable learning models) | - |

| Yuehda Industry Co.,Ltd. | Used Industrial Machinery, Articulated Robots | 100% | - | ≤12h | - | No explicit mention | - |

| Jinan Uniontech Machinery Co., Ltd. | Industrial Robotic Arms, CNC Robotics | 100% | 17% | ≤2h | US $1,000,000+ | Yes (color, material, size, logo, packaging, graphic) | Custom Manufacturer |

Performance Analysis

Jinan Uniontech and Ningbo Vichnet demonstrate high reliability with 100% on-time delivery and extensive customization capabilities, making them suitable for tailored automation projects. While Yuehda Industry also reports perfect delivery performance, its lack of reorder rate data and slower response time suggest limited repeat business visibility. Jinan Stark stands out for responsiveness (≤1h) and specialization in collaborative systems, though its 92% delivery rate indicates occasional logistical delays. Guangdong Exhibition Hall focuses on AI-integrated service robots, offering programmable learning functions ideal for dynamic factory workflows despite a lower delivery rate. Buyers seeking high-volume, standardized cobots should prioritize suppliers with documented R&D teams and modular design frameworks.

FAQs

How to verify the reliability of a factory robot supplier?

Cross-check ISO and CE certifications with issuing bodies. Request test reports for critical components such as servo motors, gearboxes, and control cabinets. Evaluate supplier credibility through verifiable transaction histories, customer reviews focusing on after-sales technical support, and facility audit trails.

What is the typical lead time for industrial robots?

New units generally ship within 30–45 days after order confirmation. Custom configurations may extend lead times to 60 days. Used or refurbished robots often have shorter wait periods (15–25 days), depending on availability and reconditioning requirements.

Do suppliers offer customization for factory automation robots?

Yes, select manufacturers provide modifications to mechanical structure, software interface, labeling, and integration protocols. Customization scope varies—confirm feasibility through technical drawings and prototype validation prior to full-scale ordering.

Can I procure used industrial robots from these suppliers?

Yes, several suppliers specialize in pre-owned robotic systems, including 6-axis articulated arms from brands like KUKA. Ensure units undergo comprehensive diagnostics and include updated firmware, safety checks, and recalibrated encoders before deployment.

What are common MOQ and pricing structures?

Minimum order quantities are typically set at 1 unit, allowing pilot testing. Pricing ranges from $6,500 for entry-level service robots to over $48,000 for high-payload used industrial arms. Bulk orders may qualify for tiered pricing and extended warranty coverage.