Shutter Making Machine Price

About shutter making machine price

Where to Find Shutter Making Machine Suppliers?

China remains the global epicenter for shutter making machine manufacturing, with key industrial clusters in Shandong and Henan provinces driving competitive pricing and technical innovation. Shandong-based suppliers, particularly around Jinan and Cangzhou, specialize in heavy-duty metal forming equipment, leveraging proximity to steel production hubs to reduce material costs by 10–15%. Henan’s Zhengzhou region focuses on automated PU sandwich panel and thermal insulation shutter lines, integrating PLC-controlled systems for high-speed output.

These regional ecosystems support vertically integrated production—from roll forming shafts to hydraulic cutting units—enabling rapid prototyping and scalable order fulfillment. Buyers benefit from concentrated supplier networks where component sourcing, machining, and final assembly occur within compact logistics zones. This structure facilitates average lead times of 25–40 days for standard configurations, with customization options widely available across core product lines such as roller shutter slat machines, full-automatic PU panel systems, and Euro-type metal shutter formers.

How to Choose Shutter Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international standards such as CE or ISO 9001, especially for buyers in regulated markets. Assess control systems (e.g., PLC integration), material handling precision (servo feeding, flying saw accuracy), and structural components (bearing grade, roller hardness). Request test reports for critical subsystems including hydraulic presses, uncoilers, and laminating dryers.

Production Capacity Verification

Evaluate infrastructure indicators to confirm scalability:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house engineering teams capable of customizing line width, panel thickness, and forming speed

- Integrated processing capabilities: CNC machining, welding, heat treatment, and assembly

Cross-reference claimed capacities with verified performance metrics such as on-time delivery rates (target ≥95%) and reorder frequency.

Procurement Risk Mitigation

Utilize secure payment mechanisms like escrow services until post-arrival inspection is completed. Prioritize suppliers with documented export experience and responsive communication (response time ≤3 hours). Conduct virtual audits via facility walkthrough videos to validate automation levels and quality control checkpoints before committing to bulk orders.

What Are the Best Shutter Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Price Range (USD) | Key Product Types |

|---|---|---|---|---|---|---|---|---|

| Jinan Steelmama International Trade Co., Ltd. | Shandong, CN | US $650,000+ | 100% | 20% | ≤2h | Color, material, size, logo, packaging, graphic | $7,500–13,850 | High-speed shutter, full-automatic PU panel, hydraulic metal former |

| Steelmama Machinery Inc | Shandong, CN | Not disclosed | Not disclosed | Not disclosed | ≤3h | Limited public data | $7,500–9,500 | PU keep-warm panel, PLC hydraulic metal former |

| Cangzhou Dixin Roll Forming Machine Co., Ltd. | Hebei, CN | US $100,000+ | 88% | 25% | ≤3h | Extensive: fire prevention, foam thickness, roller parameters, servo feeding, etc. | $5,000–9,000 | Roller shutter slat, garage door machine, thermal insulation panel |

| Zhengzhou Howann Machinery Co., Ltd. | Henan, CN | US $470,000+ | 100% | 35% | ≤1h | Motor, oil pump, bearing precision, layout, shaft design, cutters | $5,800–7,900 | Cheap-price guide rail, stainless steel shutter, rolling strip machine |

| Weihai Rosen Home Building Materials Co., Ltd. | Shandong, CN | US $40,000+ | 100% | 18% | ≤3h | Limited to wood/PVC shutters and plantation shutter parts | $1,280–$9,900 | Wood/PVC window shutters, plantation shutter manufacturing units |

Performance Analysis

Zhengzhou Howann stands out with a 35% reorder rate and sub-hour response time, indicating strong customer retention and service agility. Jinan Steelmama offers broad technical range and high transparency in customization, backed by consistent delivery performance. Cangzhou Dixin provides cost-effective solutions starting at $5,000, though its 88% on-time delivery rate suggests moderate logistical risk. Weihai Rosen caters specifically to wood and PVC shutter producers, offering entry-level machinery under $2,500 but limited to non-metal applications. Suppliers in Henan and Shandong demonstrate superior responsiveness, with 80% replying within three hours. For industrial-grade metal shutter systems, prioritize vendors with proven experience in hydraulic automation, precision rollers, and multi-layer panel lamination.

FAQs

What is the typical MOQ and pricing for shutter making machines?

Most suppliers set a minimum order quantity of 1 set, with prices ranging from $1,280 for basic wood/PVC models to over $13,000 for fully automated metal or PU insulation lines. High-efficiency, PLC-controlled systems typically start at $7,500.

How long does production and shipping take?

Lead times average 25–40 days for manufacturing, depending on customization complexity. Sea freight adds 20–35 days for international delivery. Air shipment is not viable for complete lines due to size and weight constraints.

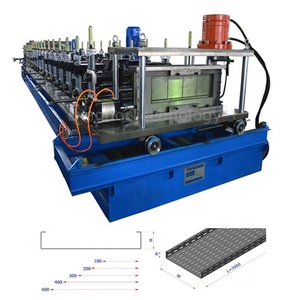

Can suppliers customize machine specifications?

Yes, most established manufacturers offer extensive customization, including panel width (800–1,200mm), forming speed (10–30m/min), material thickness (0.3–1.2mm), and integration of uncoilers, pre-punching units, and flying saws. Technical drawings and layout plans are typically provided within 72 hours of inquiry.

Do suppliers provide installation and after-sales support?

Support varies. Some include remote guidance or instructional videos; others offer on-site technician deployment at additional cost. Confirm service scope prior to purchase, including warranty duration (typically 12 months) and spare parts availability.

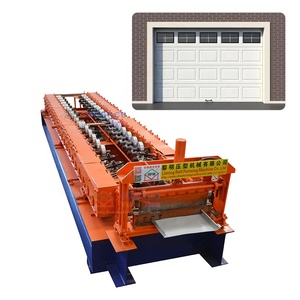

Are there differences between metal and wood shutter machines?

Yes. Metal shutter machines use cold roll forming technology with hydraulic cutting and PLC controls, suitable for steel or aluminum coils. Wood/PVC shutter machines rely on woodworking routers, planers, and assembly jigs. The two systems are not interchangeable and require distinct workshop setups and operator skills.